Drawing frame and sliver blocking sensor

A sensor, draw frame technology, used in spinning machines, textiles and paper, drafting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

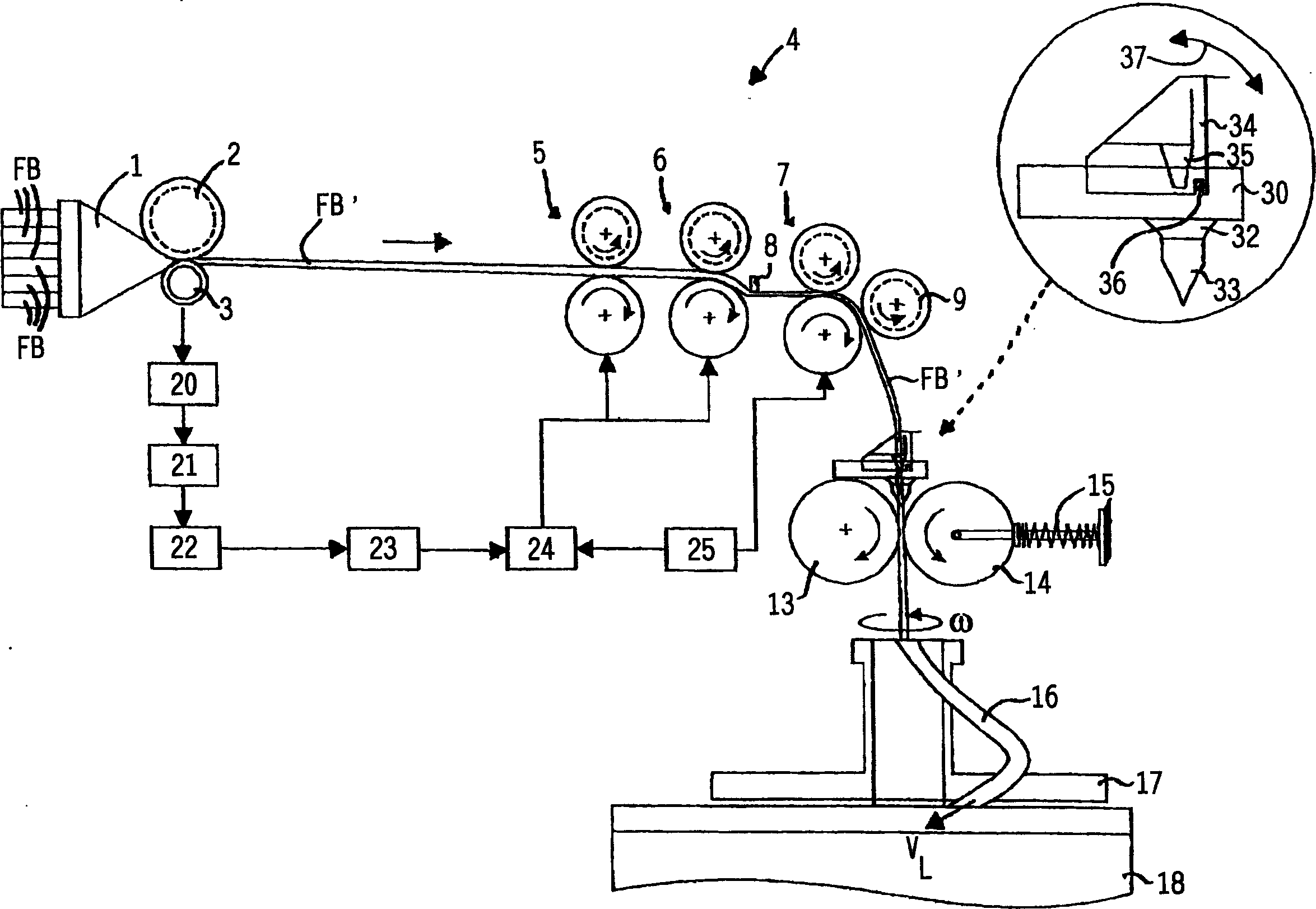

[0035] The following is based on figure 1Describe the basic operating principle of the draw frame. According to an example of the prior art, a plurality of untwisted draw frame slivers FB are fed side by side. It is also possible to feed only one fiber sliver FB to the draw frame. A trumpet head 1 of compacted fiber sliver FB is arranged at the input end of the draw frame. Other compaction devices may also be used. A compacted fiber strip FB' consisting of a plurality of individual fiber strips FB is fed into a drafting device 4 by means of a detection device 2, 3 consisting of a pair of rollers. Its drafting unit 4 generally comprises three drafting elements or roller pairs, between which the actual drafting takes place. The pairs of rollers are input roller pairs 5, intermediate roller pairs 6 and output or supply roller pairs 7, which rotate at successively increasing peripheral speeds. With such a configuration, the fiber strand FB' is drawn according to the periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com