Inductive motor and method for producing induction motor rotor and stator

A technology of induction motor and manufacturing method, which is applied in the field of stator manufacturing, induction motor and induction motor rotor, can solve the problems of large resistance, reduce the efficiency of induction motor, cannot ensure insulation, etc., so as to reduce iron loss and shorten eddy current path. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

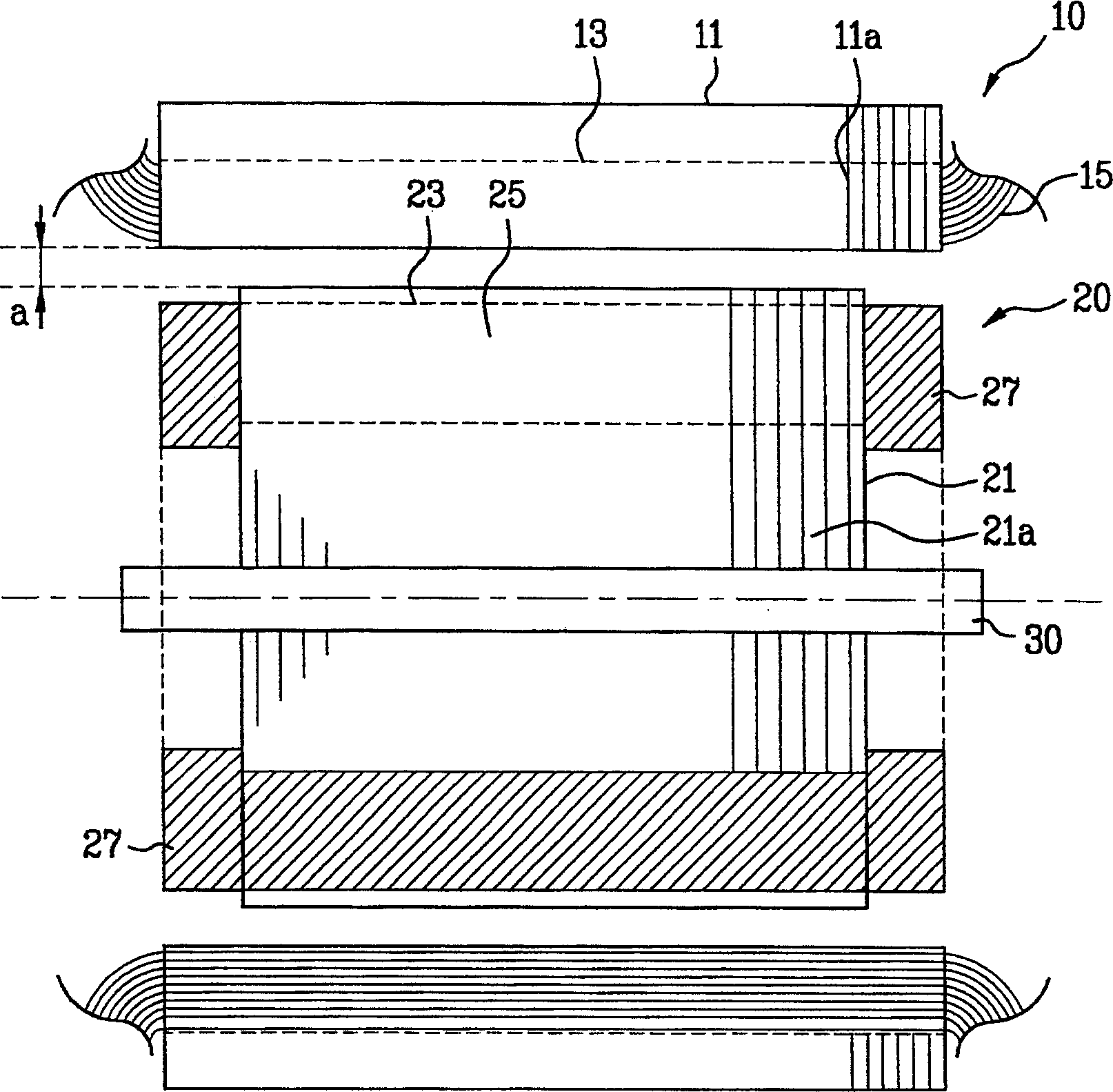

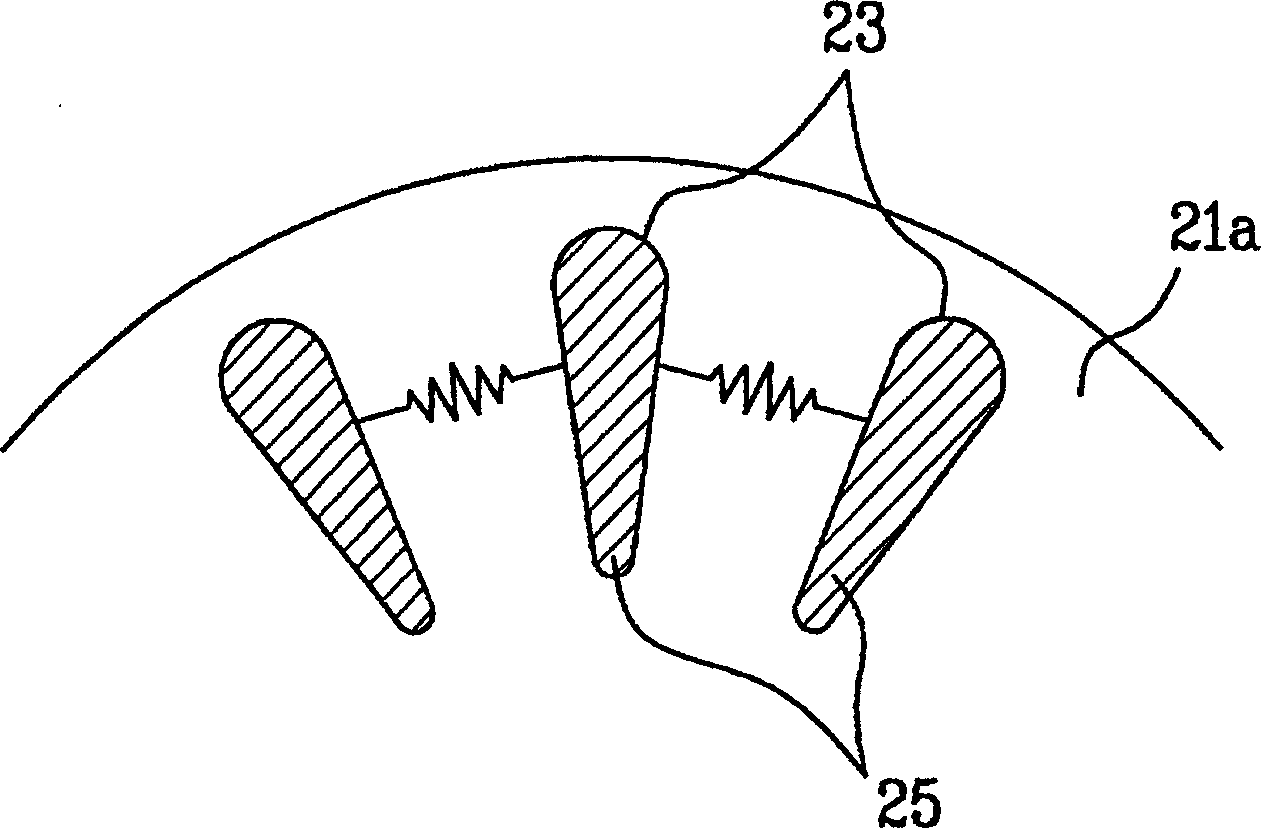

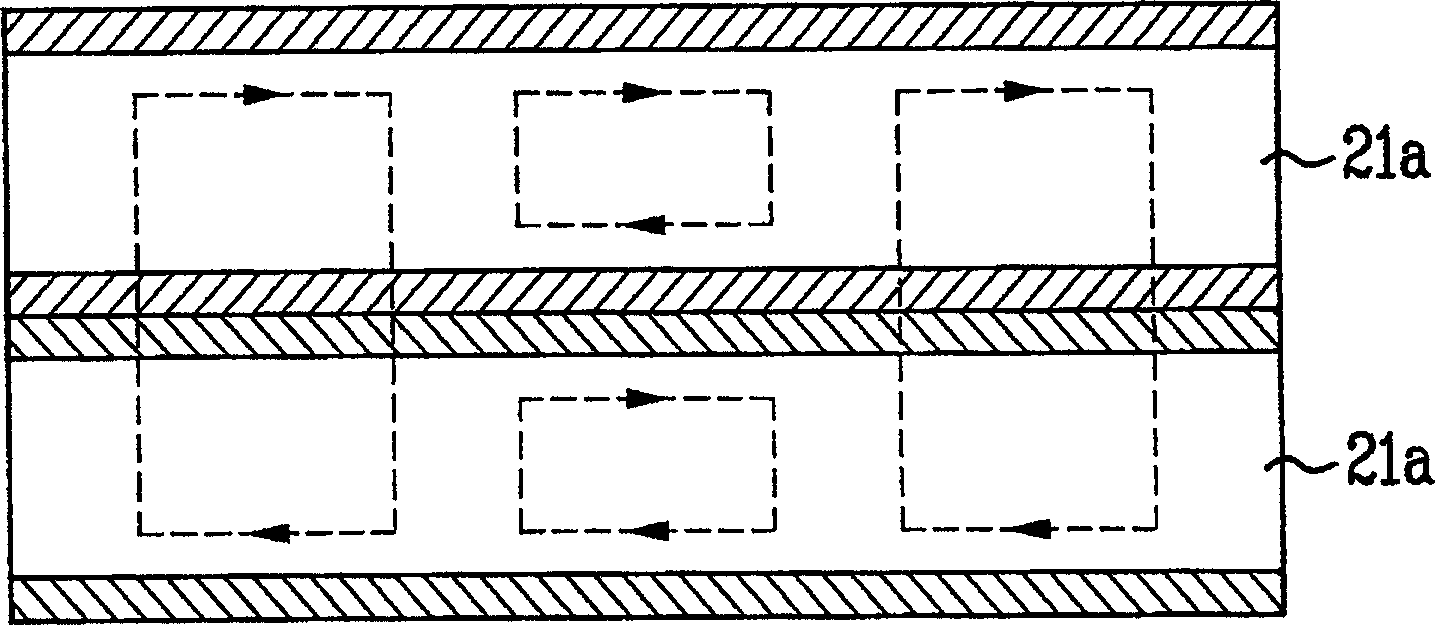

[0045] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: image 3 is a cross-sectional view of the structure of the induction motor according to the first embodiment of the present invention. Figure 4 yes image 3 Partial cross-sectional view of the rotor silicon steel sheet of an induction motor. Figure 5a yes image 3 Flowchart of the induction motor fabrication method. Figure 5b yes image 3 A flowchart of the induction motor manufacturing method and a detailed flowchart of the insulating film formation stage.

[0046] Such as image 3 As shown, the induction motor of the first embodiment of the present invention has the following structure: the induction motor is generally composed of a stator 10 , a rotor 20 and a shaft 30 . The rotor 20 forms a concentric circle with the stator 10 and maintains a certain gap a with the inner peripheral edge of the stator 10 . The shaft 30 is press-fitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com