Nano antibacterial non-woven fabric filtering material and its preparation method

A nano antibacterial powder, non-woven technology, applied in the directions of botanical equipment and methods, separation methods, chemical instruments and methods, can solve the problems of silver ion precipitation and loss, reduction of antibacterial and bactericidal effects, etc., and achieve good antibacterial effect. , obvious antibacterial effect, strong antibacterial and bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

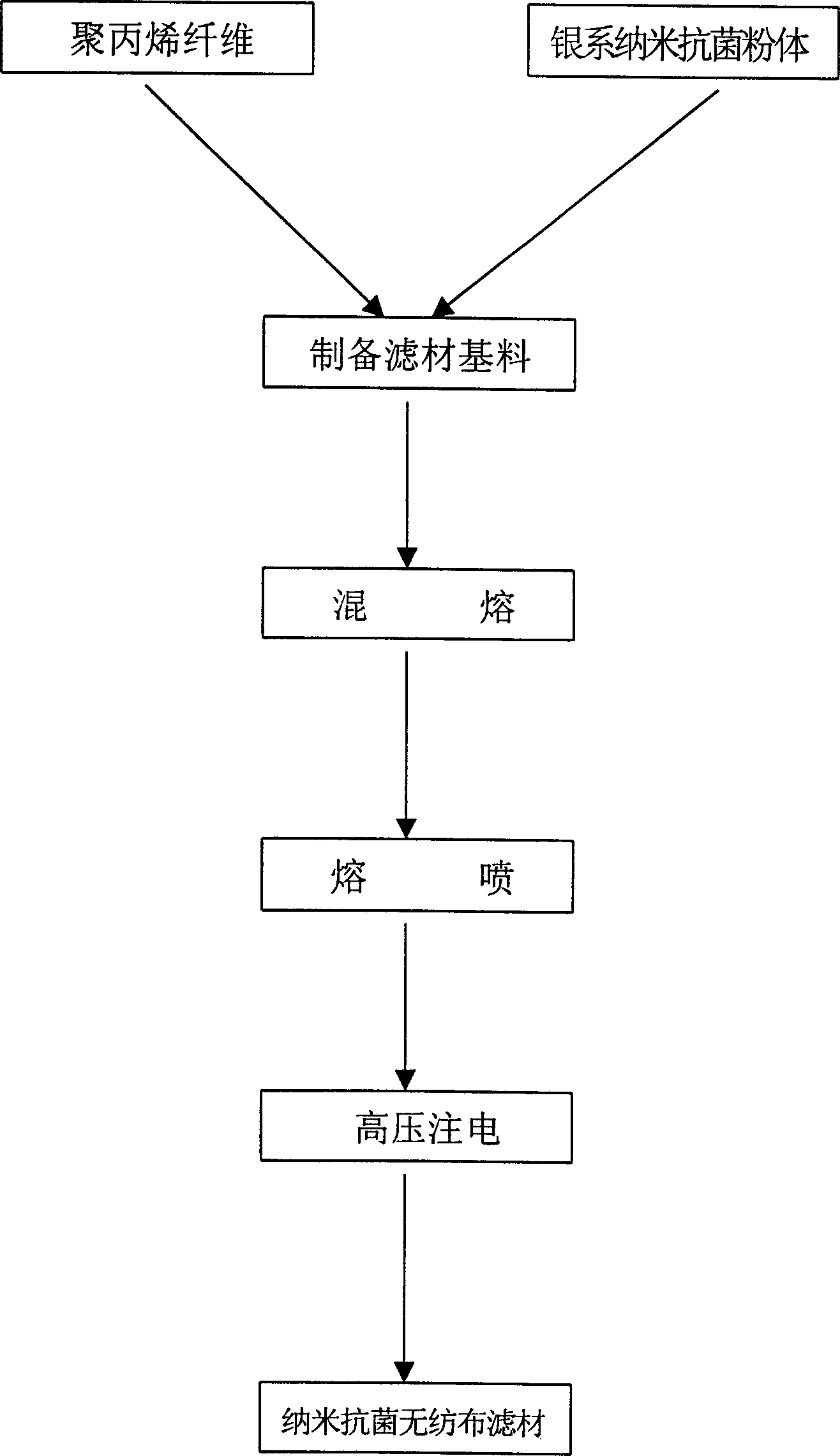

[0018] Prepare the preparation method of above-mentioned nano antibacterial non-woven fabric:

[0019] A. Preparation of non-woven filter material base material

[0020] First, weigh the polypropylene fiber and the silver-based nano-antibacterial powder according to the above-mentioned ratio of parts by weight, put the two into a high-speed stirrer and fully stir and mix them for ten minutes to make the base of the antibacterial non-woven filter material. material;

[0021] B. Mixed melting

[0022] Put the base material of non-woven filter material into the extruder, the inner temperature is 140-180℃, 4-6kg / cm 3 Mixing and melting under working conditions, extruded to make a liquid mixture;

[0023] C. Meltblown

[0024] Fill into the melt-blown injection molding equipment in the ultraviolet disinfection workshop, at 140-180°C, 4-6kg / cm 3 Under the working conditions of the melt-blown injection molding machine, the liquid mixture is melt-blown and injected, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com