New type composite board and its processing technology

A processing technology and composite board technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of board limitation, heavy, high production cost, reduce processing and material costs, and facilitate locking The effect of joining and snapping, enhancing the strength of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

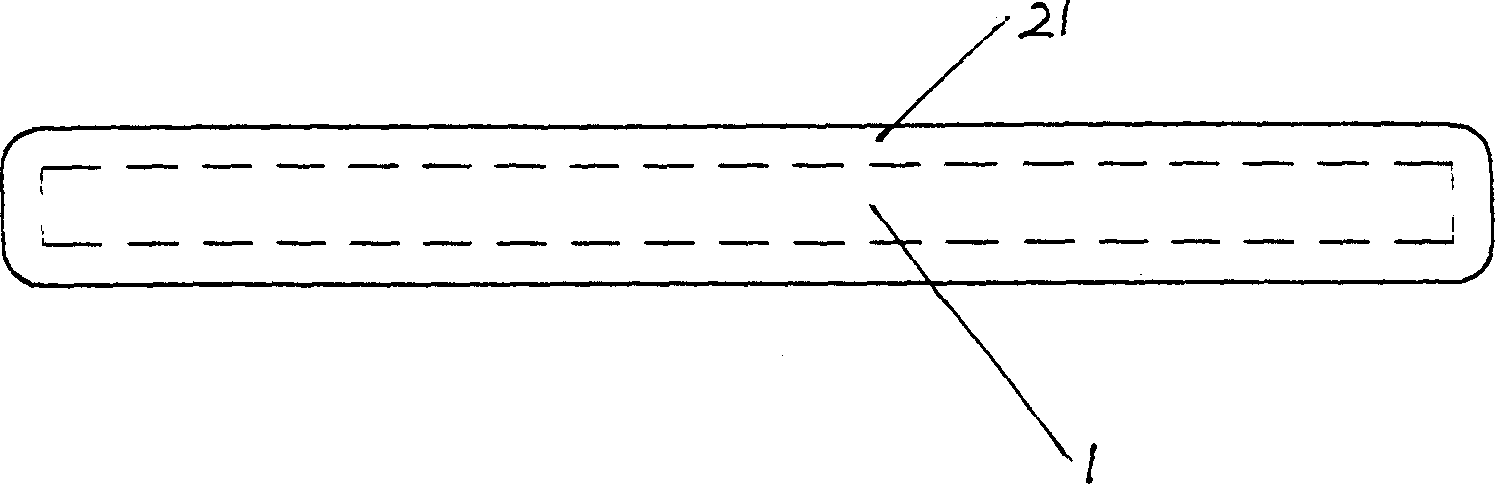

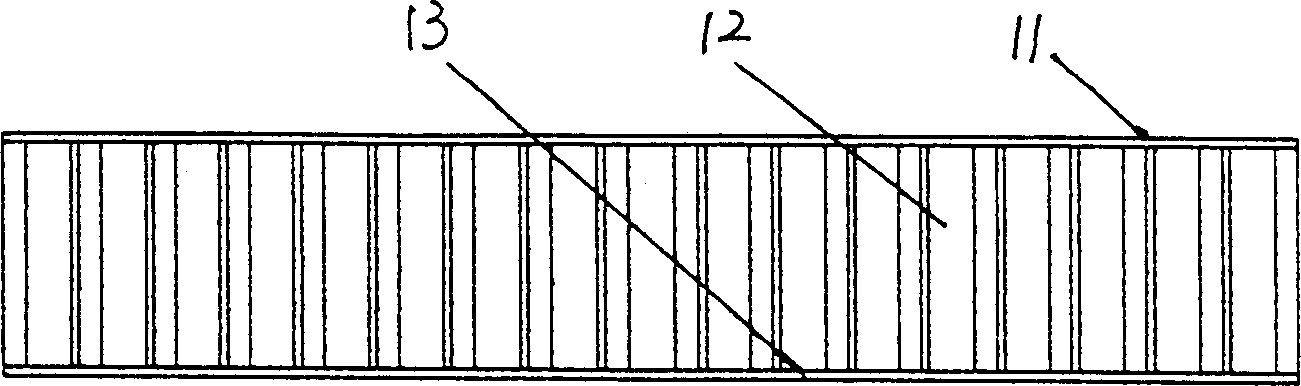

[0047] Embodiment one, see figure 1 , figure 2 , as shown in Figure 3, the present embodiment is to produce a polyurethane rigid foam desktop, wherein the honeycomb panel 1 is made of honeycomb paper 12, face paper 11, and base paper 13, and the honeycomb paper 12 is sandwiched between the face paper 11 and the base paper 13 between, and bonded with the surface paper 11 and the bottom paper 13, the honeycomb panel 1 is made into a square shape; the plastic foam filler 21 is made of white material and black material at a ratio of 1:1.05; the black material is MDI, which can be made of It is purchased directly from the market, and the white material is prepared according to the following ratio (weight ratio):

[0048] Mixed Polyether 100

[0049] Amine Catalyst C 2.0

[0050] Silicon Copper Foam Stabilizer 2.0

[0051] water 2.0

[0052] Physical blowing agent 28

[0053] First put the white material weighed in the above preparation ratio into the mixe...

Embodiment 2

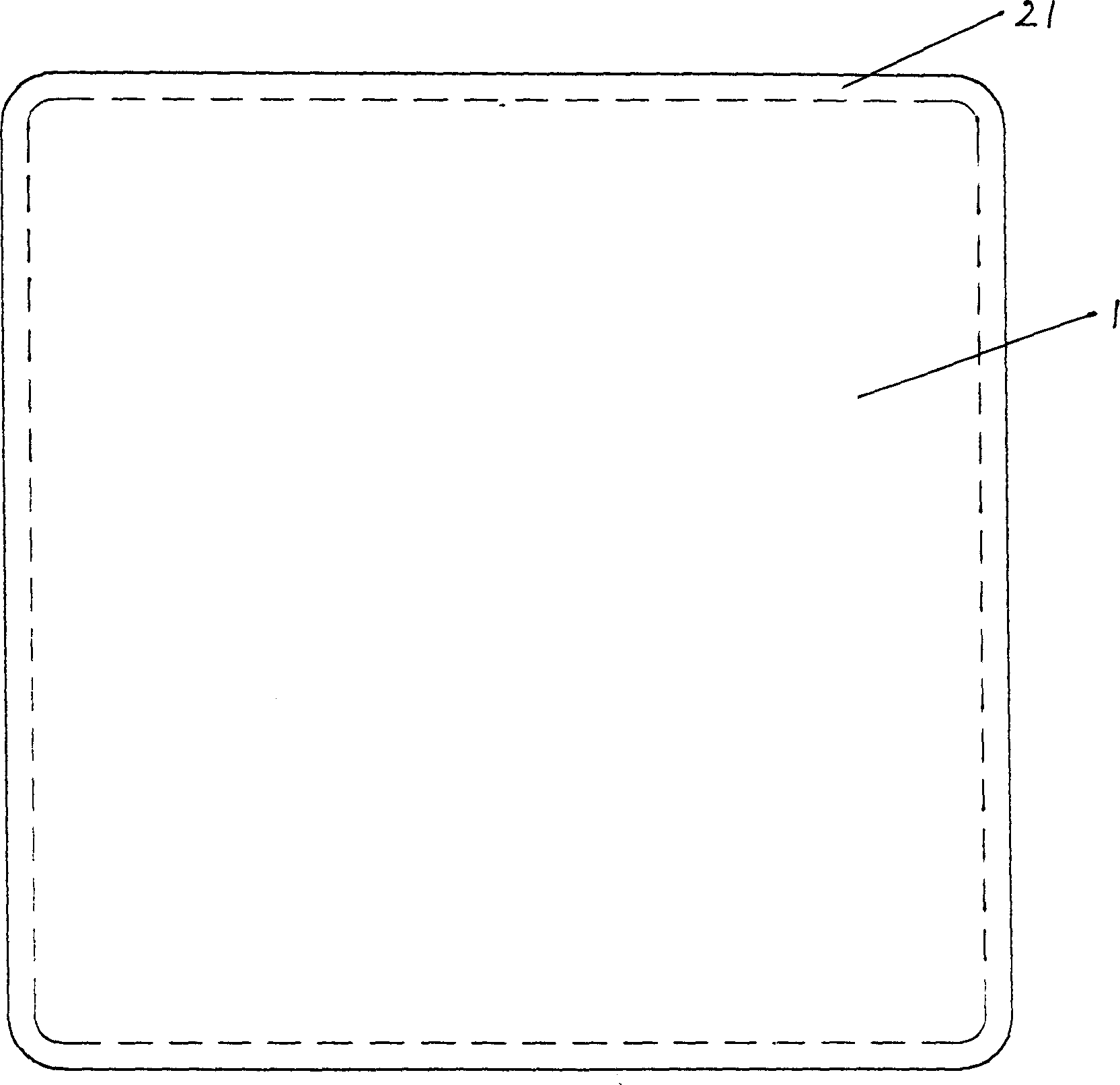

[0063] Embodiment two, referring to Fig. 3, Figure 4 , Figure 5 As shown, this embodiment is to produce a molded self-skinned table top, wherein the honeycomb panel 1 is composed of honeycomb paper 12, face paper 11, and base paper 13, and the honeycomb paper 12 is sandwiched between the face paper 11 and the base paper 13 , and bonded with the surface paper 11 and the bottom paper 13, the honeycomb panel 1 is made into a circular shape; the plastic foam filling body 22 is compounded by white material and black material in a ratio of 100:40~60; the black material is composed of two It is composed of phenylmethane diisocyanate and toluene diisocyanate, which can be purchased directly from the market. The white material is prepared according to the following ratio (weight ratio):

[0064] Mixed Polyether 100

[0065] Amine Catalyst A 2.0

[0066] Amine catalyst B 0.1

[0067] Silicon Copper Foam Stabilizer 2.0

[0068] Cross-linking agent 0.5

[0069]...

Embodiment 3

[0080] Embodiment three, referring to Fig. 3, Image 6 , Figure 7 As shown, the novel composite panel of the present invention includes a honeycomb panel 1, a plastic foam filling body 23, and an angular metal reinforcing plate 32. The honeycomb panel 1 is composed of a honeycomb paper 12, a face paper 11 and a bottom paper 13. Between the surface paper 11 and the bottom paper 13, and bonded with the surface paper 11 and the bottom paper 13; put the honeycomb panel 1 on the process ejector pin of the mold cavity to be formed, and place it on the two ends of the honeycomb panel 1 Add an angular metal reinforcing plate 32 each, inject plastic foam filling material and close the mold, the top of the mold cavity is a curved surface, the bottom is a plane, and the shape is square, and the plastic foam filling material fills the honeycomb panel 1. Angular metal The non-contact gap between the reinforcing plate 32 and the mold cavity makes the honeycomb panel 1, the angular metal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com