Device for welding nut or the like

A welding device and nut technology, applied in welding equipment, resistance welding equipment, pressure electrodes, etc., can solve the problems of difficult and precise detection, position accuracy error, easy wear of cylinders, etc., and achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

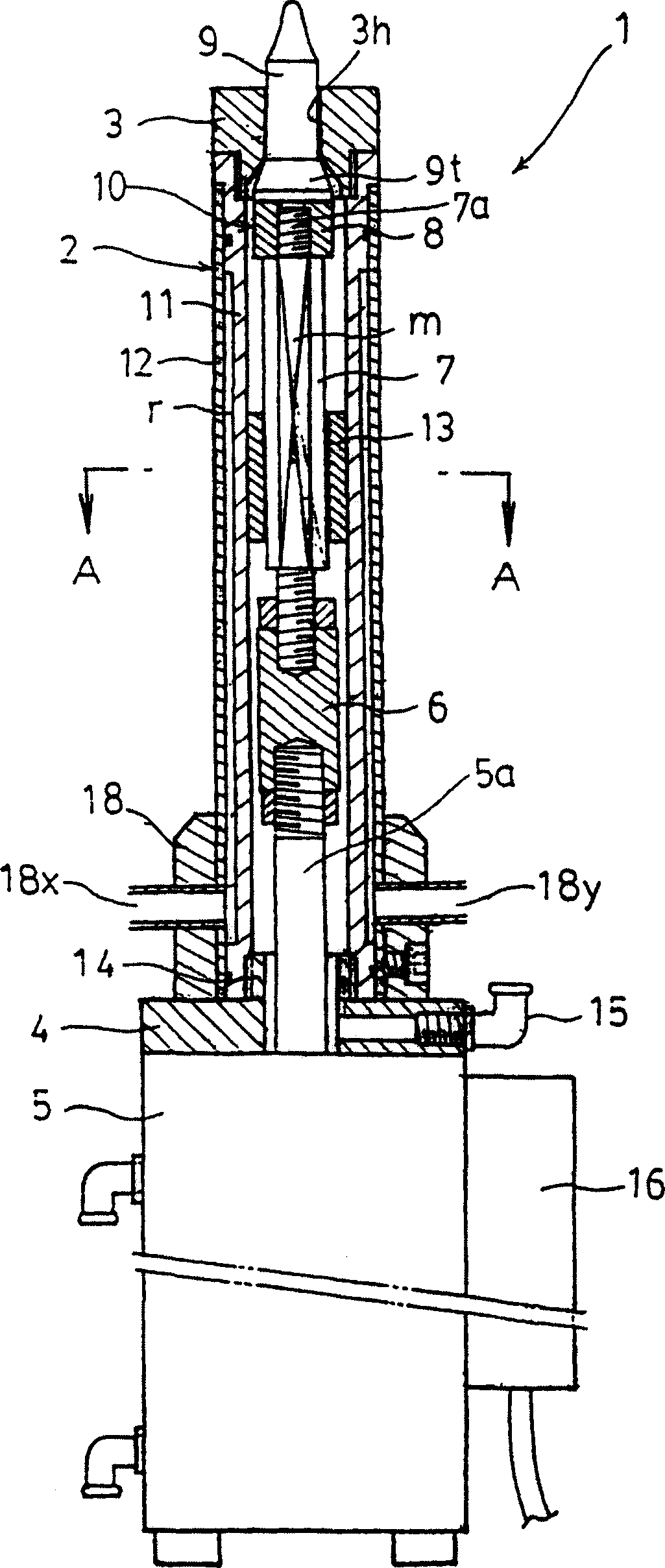

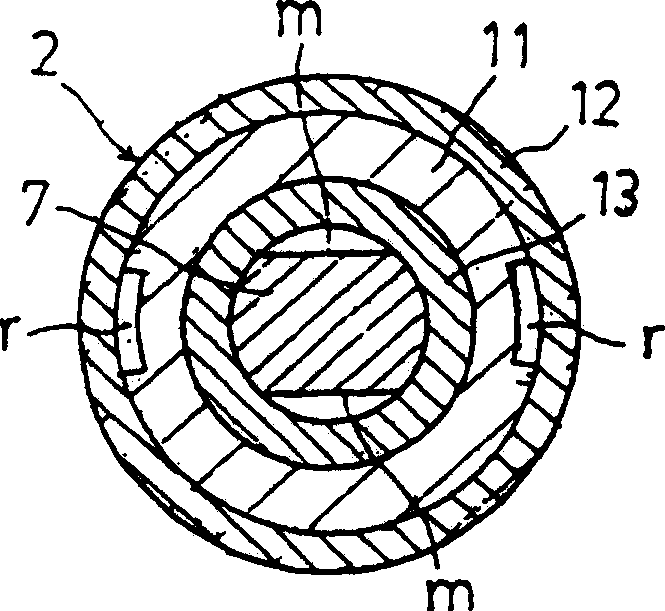

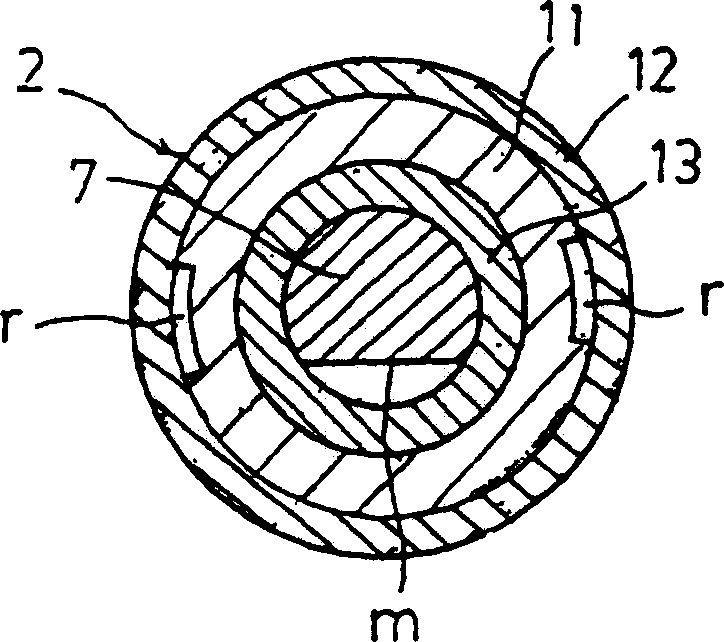

[0046] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

[0047] The welding device 1 such as a nut of the present invention is made so that it can accurately detect the protruding position of the positioning pin, and at the same time, it can prevent spatters generated during welding from entering the cylinder of the electrode holder, thereby improving the life. Such as figure 1 As shown, it has an electrode holder 2 with a double cylinder structure, a lower electrode 3 connected to the top of the electrode holder 2, and a cylinder 5 connected to the bottom of the above-mentioned electrode holder 2 through an insulating material, and the connecting rod 7 is connected to the bottom of the electrode holder 2 through an insulating material. While on the cylinder rod 5a of the above-mentioned cylinder 5, a pin connecting portion 10 is arranged on the top of the connecting rod 7. In this embodiment, a ceramic positioning pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com