Multi-junction solar cell, photovoltaic conversion component and compound semiconductor layer-by-layer structure

A technology for solar cells and compounds, applied in electrical components, semiconductor devices, energy conversion devices, etc., can solve problems such as lattice mismatch and quality degradation of compound semiconductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

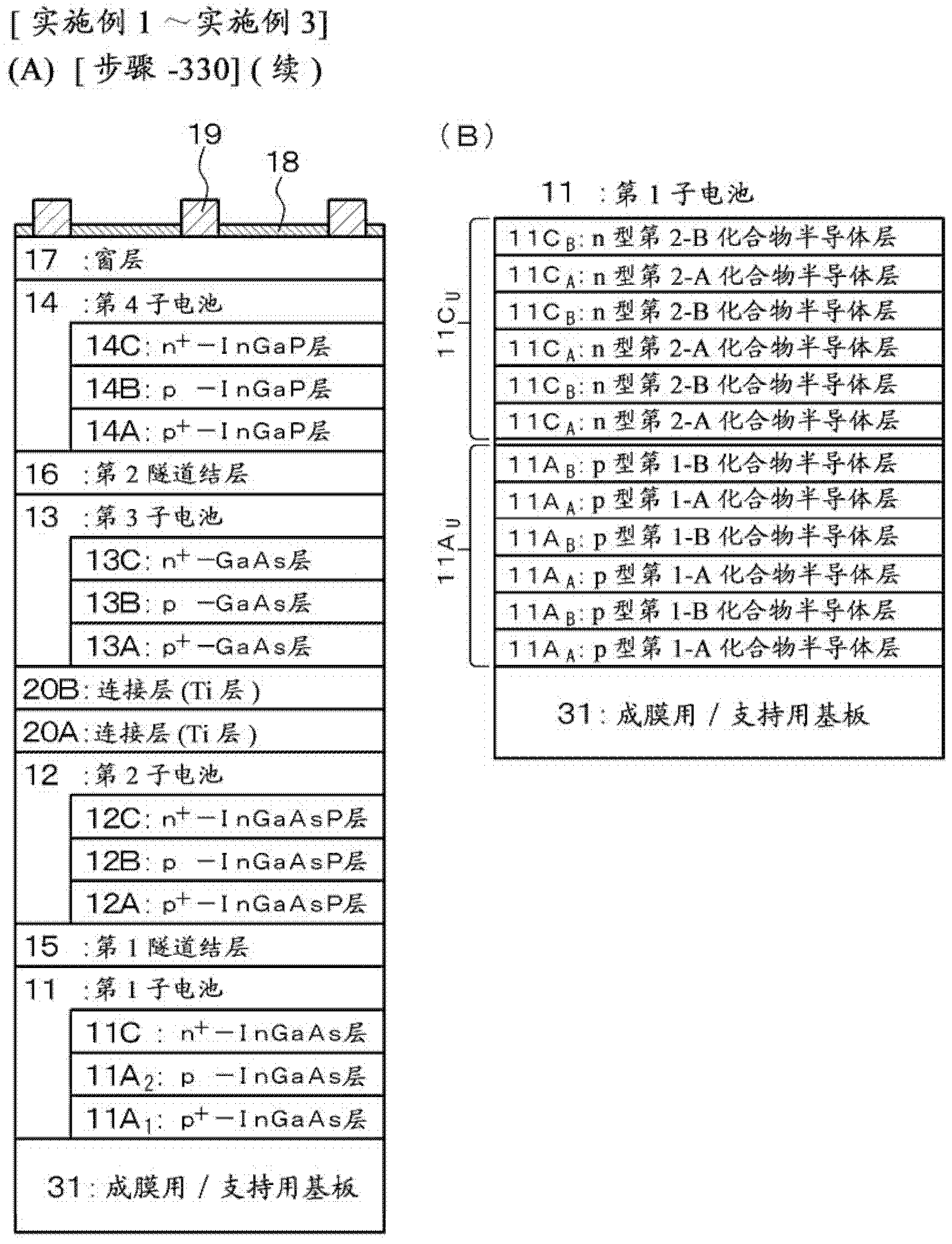

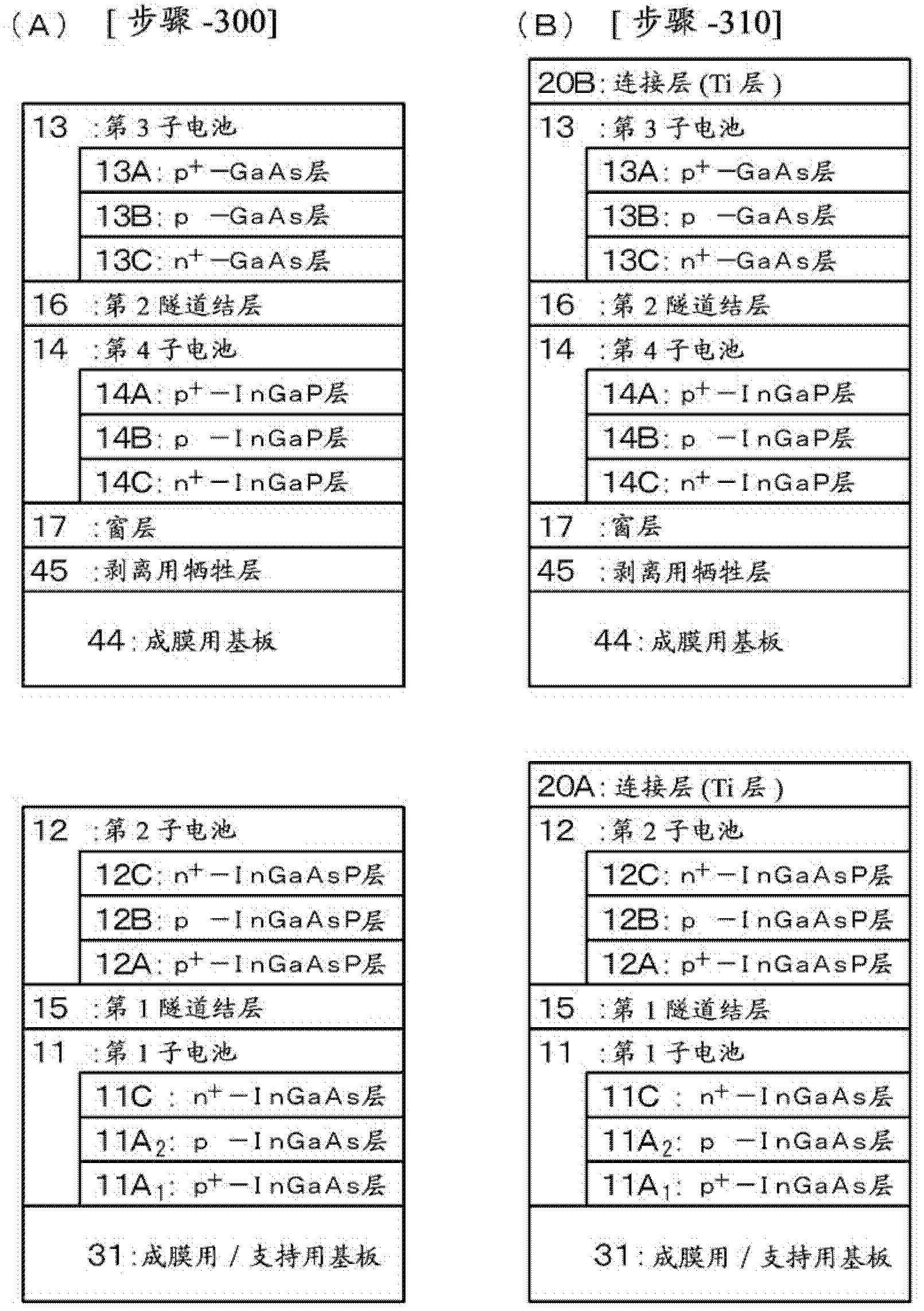

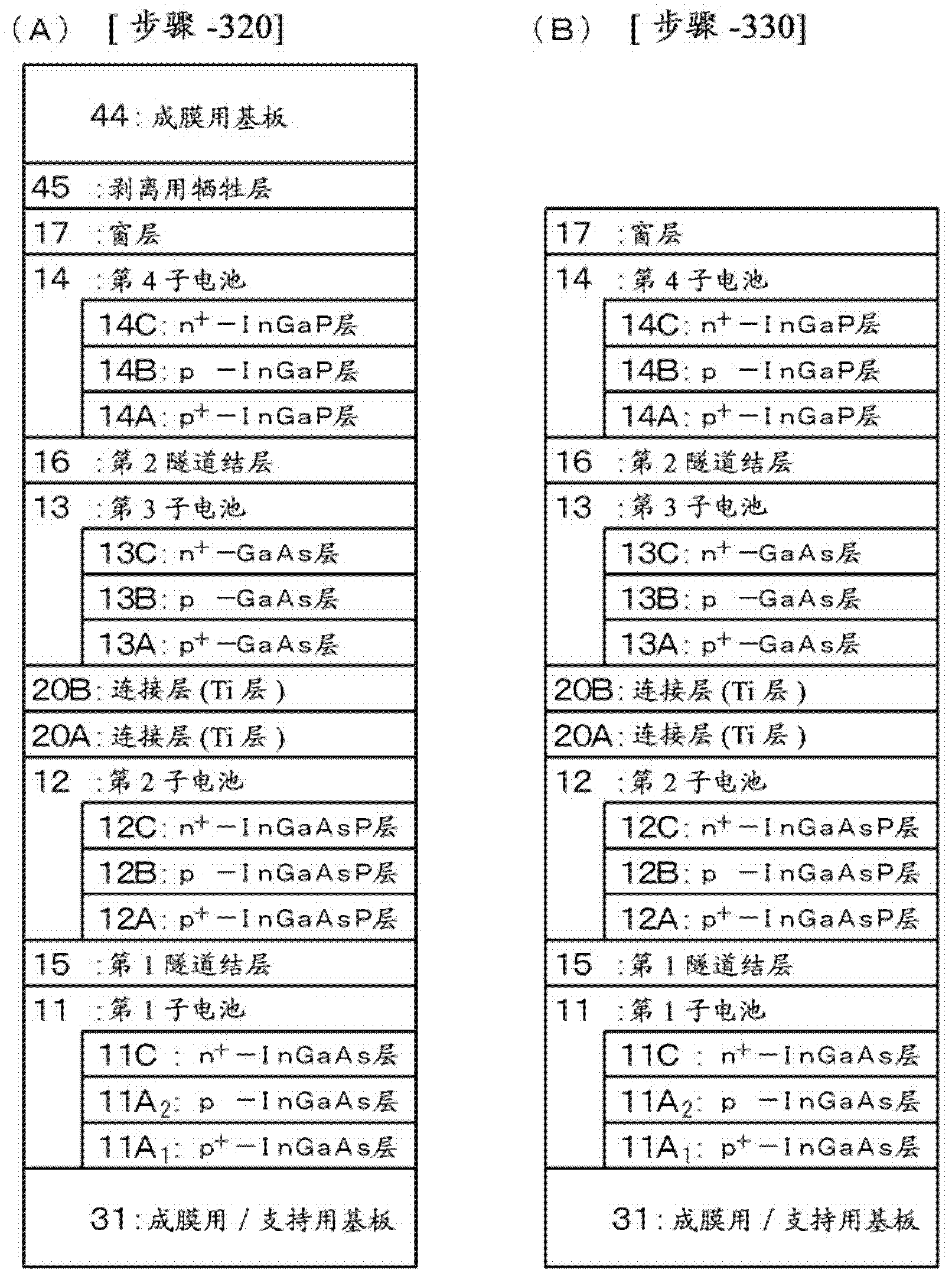

[0112] 2. Example 1 (multi-junction solar cell, photoelectric conversion element, and compound semiconductor layer stacked structure of the present invention)

Embodiment 2

[0113] 3. Embodiment 2 (variation of embodiment 1)

[0114] 4. Embodiment 3 (other modifications of Embodiment 1)

[0115] 5. Embodiment 4 (variation of embodiment 3)

[0116] 6. Embodiment 5 (other modifications of Embodiment 3)

Embodiment 6

[0117] 7. Embodiment 6 (further other modifications of Embodiment 3)

[0118] 8. Embodiment 7 (variation of Embodiment 6), others

[0119] [Comprehensive description of the multi-junction solar cell, photoelectric conversion element, and compound semiconductor layered structure of the present invention]

[0120] In the multi-junction solar cell of the present invention, the specific sub-cell may be located in the lowest layer. The stacking order of the plurality of sub-cells is as follows: the closer to the light incident side, the larger the band gap of the compound semiconductor constituting the sub-cells, that is, from a support substrate, etc. to be described later. From the side to the second electrode side, the band gap increases sequentially. As the case may be, a portion of the plurality of subcells may consist of a Ge layer.

[0121] For the multi-junction solar cell of the present invention, the photoelectric conversion element of the present invention, or the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com