Capacitor element of solid electrolytic capacitor and method for manufacturing the same, solid electrolytic capacitor

A technology of solid electrolysis and capacitors, which is applied in the direction of solid electrolytic capacitors, electrolytic capacitors, fixed capacitor parts, etc., can solve the problems of unavoidable reduction of capacitor capacity, reduce the occurrence rate of defective products, simplify the process, and avoid large-scale Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

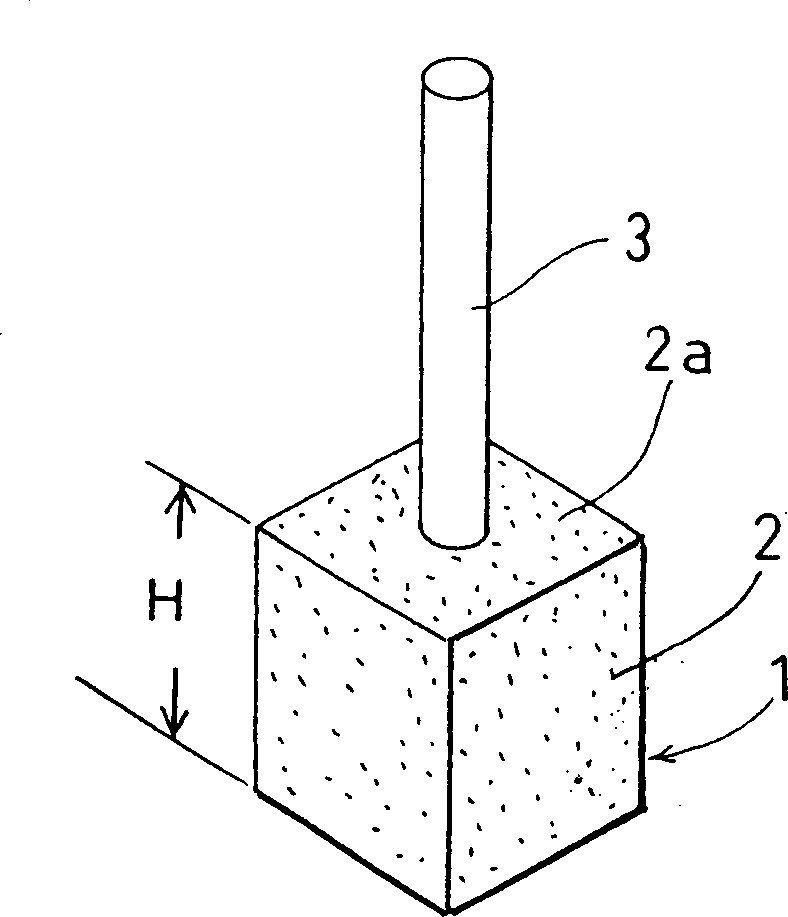

[0104] First, tantalum powder such as Figure 16 As shown, the porous anode electrode body 22 is fixed and then sintered, and an anode metal wire 23 made of tantalum and having a diameter d0 (about 150 to 200 micrometers) protrudes from one end surface 22 a of the anode electrode body 22 .

[0105] On the other hand, from a plate made of a raw material such as a transparent thermoplastic synthetic resin having hydrophobicity and thermal shrinkage such as a fluororesin with a melting point of about 270°C, through perforation, etc., such as Figure 16 As shown, an annular body 28 having a thickness T (about 100 micrometers) and a diameter D (about 600 micrometers) having a through hole 28 a with an inner diameter d is fabricated in advance. Then, if Figure 17 As shown, the annular body 28 is embedded and installed on the root of the anode metal wire 23 with a diameter d0 protruding from one end surface 22a of the anode electrode body 22 relative to the anode electrode body 22,...

Embodiment 3

[0124] First, if Figure 22 As shown, tantalum powder is fixed to form a porous anode electrode body 32 and then sintered, and an anode wire 33 made of tantalum protrudes from one end surface 32 a of the anode electrode body 32 .

[0125] When the anode electrode body 32 is fixedly formed, a recess 32c having a depth h that surrounds the anode wire 33 protruding from the end surface 32a is provided on the end surface 32a.

[0126] On the other hand, from a raw material plate made of a hydrophobic transparent thermoplastic synthetic resin such as a fluorine-based resin with a melting point of about 270°C, through perforation, etc., such as Figure 22 As shown, an annular body 38 having a thickness dimension T having a through hole 38a is prepared in advance. Then, if Figure 23 As shown, the annular body 38 is embedded and mounted on the root of the anode metal wire 33 protruding from one end surface 32 a of the anode electrode body 32 relative to the anode electrode body 32 ...

Embodiment 4

[0143] First, if Figure 27 As shown, tantalum powder is fixed to form a porous anode electrode body 42 and then sintered, and an anode wire 43 made of tantalum protrudes from one end surface 42 a of the anode electrode body 42 .

[0144] On the other hand, from a raw material sheet made of a transparent thermoplastic synthetic resin such as a fluorine-based resin with a melting point of about 270°C that is hydrophobic and shrinkable when heated, through perforation, etc., such as Figure 27 As shown, an annular body 48 having a through hole 48a having an inner diameter d, a thickness dimension T, and a diameter D is prepared in advance. Then, if Figure 28 and Figure 29 As shown, the annular body 48 is inserted and installed in the base of the anode wire 43 protruding from the one end surface 42 a of the anode electrode body 42 relative to the anode electrode body 42 .

[0145] Next, the anode electrode body 42 is kept in an upward posture with its end surface 42a facing up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com