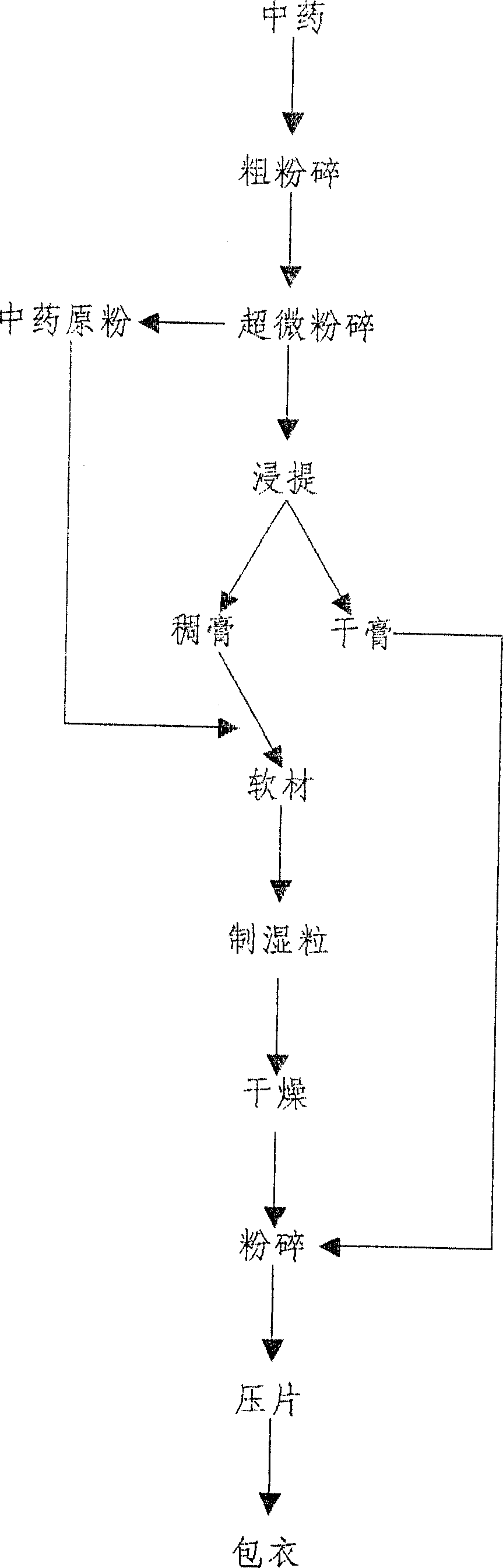

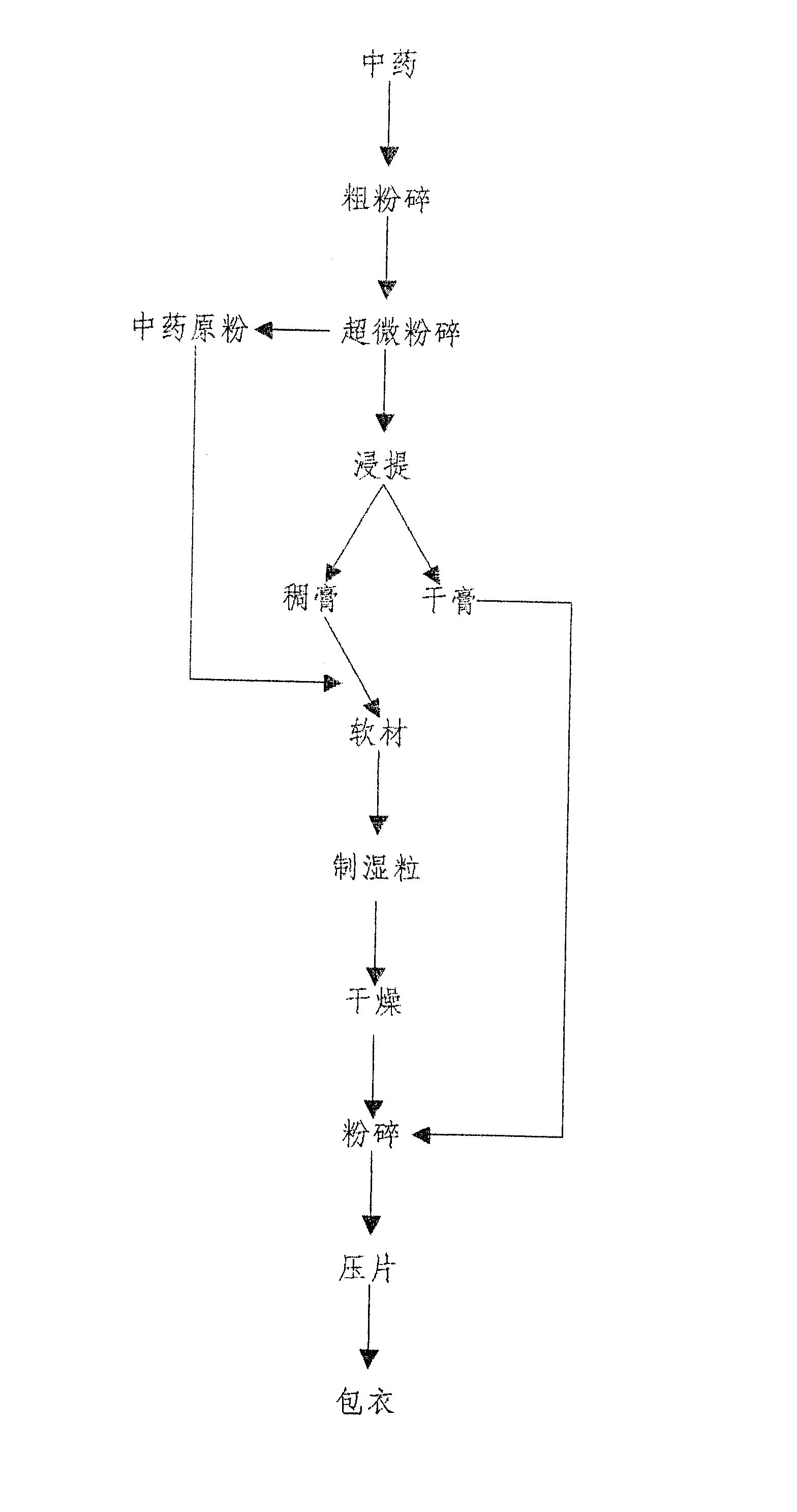

Method for preparing Chinese medicinal tablet by ultramicropulverization technology

An ultrafine pulverization technology and ultrafine pulverizer technology, which are applied in the direction of medical formula, medical preparations containing active ingredients, pill delivery, etc., can solve the problems of high waste of traditional Chinese medicine resources, low extraction rate of active ingredients, and low utilization rate of drugs and other problems, to achieve the effects of quick onset, saving of traditional Chinese medicine resources, and high utilization of medicines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After the traditional Chinese medicine is crushed into coarse particles with a particle size of 200 mesh, it is injected into a superfine pulverizer together with freeze-dried air at a temperature of 0°C and a water content of 0.5%, and a high-speed airflow is used to prepare an ultrafine Chinese medicine powder with a particle size of 2500 mesh . The Miyou brand airflow mill was selected as the ultrafine pulverizer, the product model is QYF-260, the working pressure is 1MP, the internal working temperature is 8°C, and the pressure of the compressed air is 0.8MP. When the coarse particles of traditional Chinese medicine are ultrafinely pulverized, the airflow accompanied by ultrafine traditional Chinese medicine powder is filtered and collected by dust removal to make ultrafine traditional Chinese medicine powder.

[0022] Take out 1 / 5 of the ultrafine Chinese medicine powder and mix it into the original Chinese medicine powder for later use; fully dissolve the remainin...

Embodiment 2

[0032] After the traditional Chinese medicine is crushed into coarse particles with a particle size of 60 mesh, it is injected into a superfine pulverizer together with freeze-dried air at a temperature of 10°C and a water content of 1%, and a superfine Chinese medicine powder with a particle size of 1250 mesh is prepared by high-speed airflow . The Miyou brand jet mill was selected as the ultrafine pulverizer, the product model is QYF-260, the working pressure is 1.5MP, the internal working temperature is 3°C, and the pressure of the compressed air is 1MP. When the coarse particles of traditional Chinese medicine are ultrafinely pulverized, the airflow accompanied by ultrafine traditional Chinese medicine powder is filtered and collected by dust removal to make ultrafine traditional Chinese medicine powder.

[0033] Take out 1 / 3 of the superfine Chinese medicine powder and mix it into the original Chinese medicine powder for later use; fully dissolve the remaining superfine C...

Embodiment 3

[0037] After the traditional Chinese medicine is crushed into coarse particles with a particle size of 300 mesh, it is injected into a superfine pulverizer together with freeze-dried air at a temperature of 5°C and a water content of 0.1%, and a superfine Chinese medicine powder with a particle size of 12,500 mesh is prepared by high-speed airflow . The Miyou brand airflow mill was selected as the ultrafine pulverizer, the product model is QYF-260, the working pressure is 0.9MP, the internal working temperature is 10°C, and the pressure of the compressed air is 1.5MP. When the coarse particles of traditional Chinese medicine are ultrafinely pulverized, the airflow accompanied by ultrafine traditional Chinese medicine powder is filtered and collected by dust removal to make ultrafine traditional Chinese medicine powder.

[0038] Take out 1 / 4 of the ultrafine Chinese medicine powder and mix it into the original powder of traditional Chinese medicine for later use; fully dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com