Beating arrangement

A hammer and component technology, applied in the direction of grain processing, etc., can solve the problem of the knife body being useless, and achieve the effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

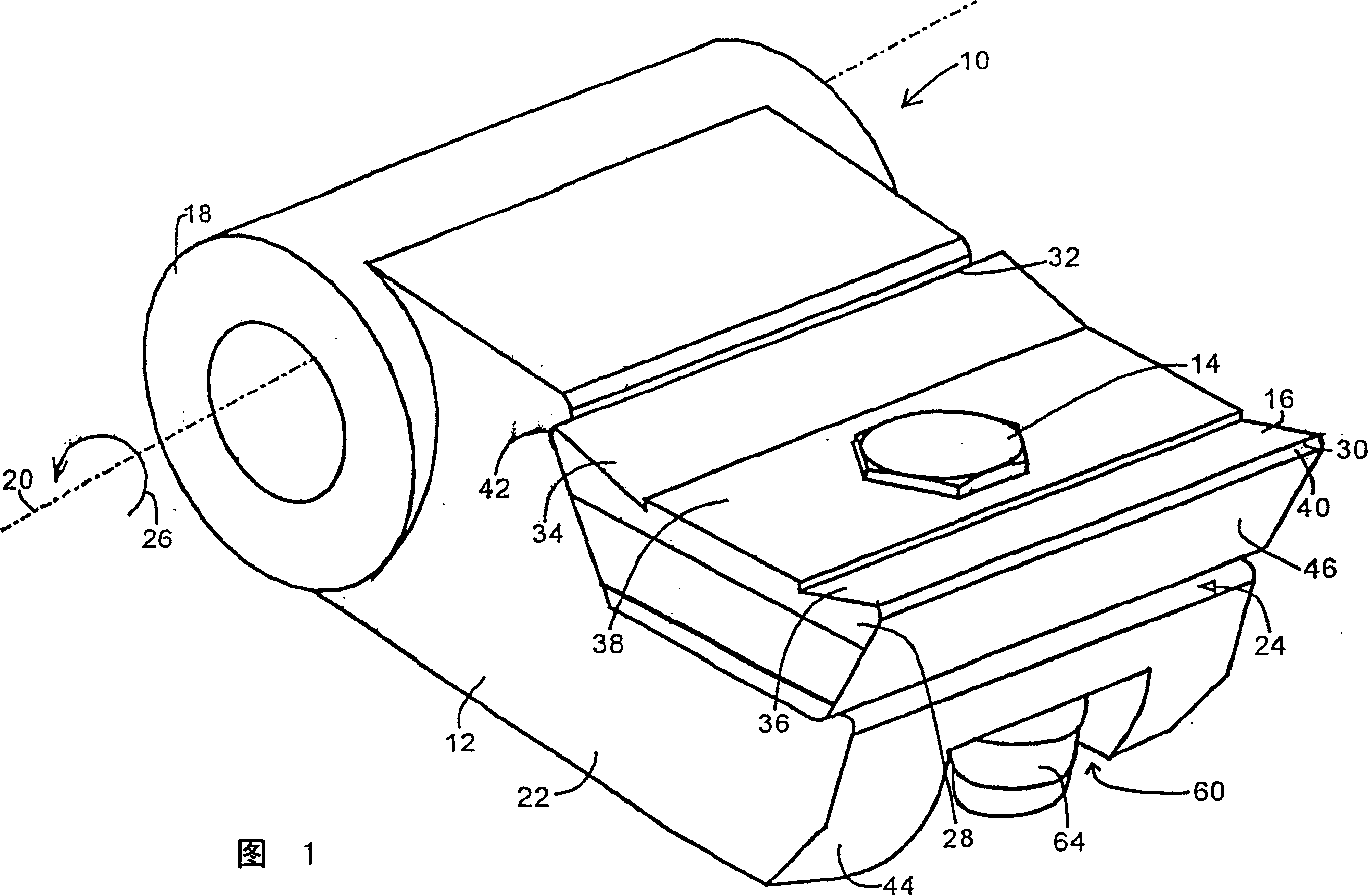

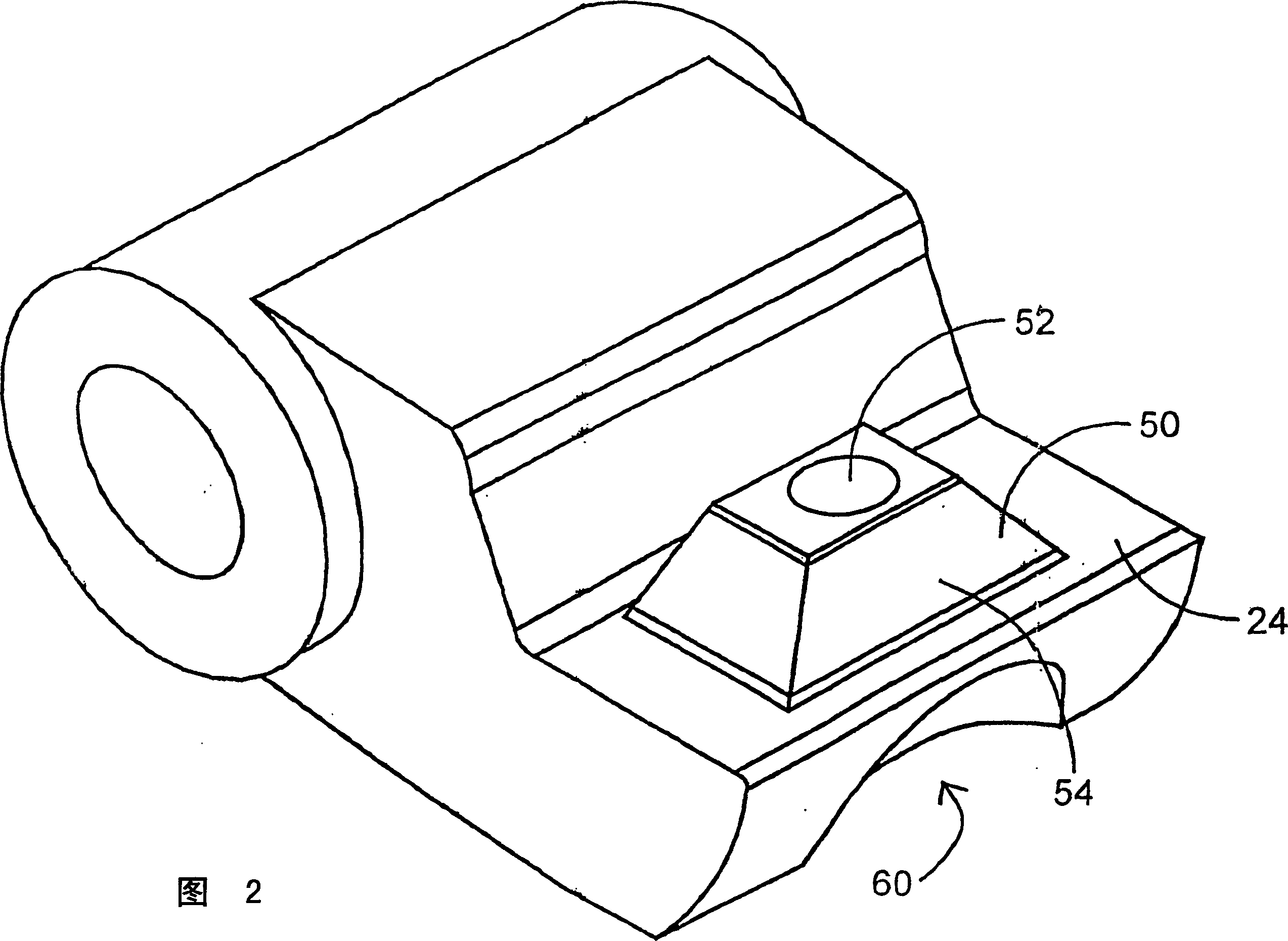

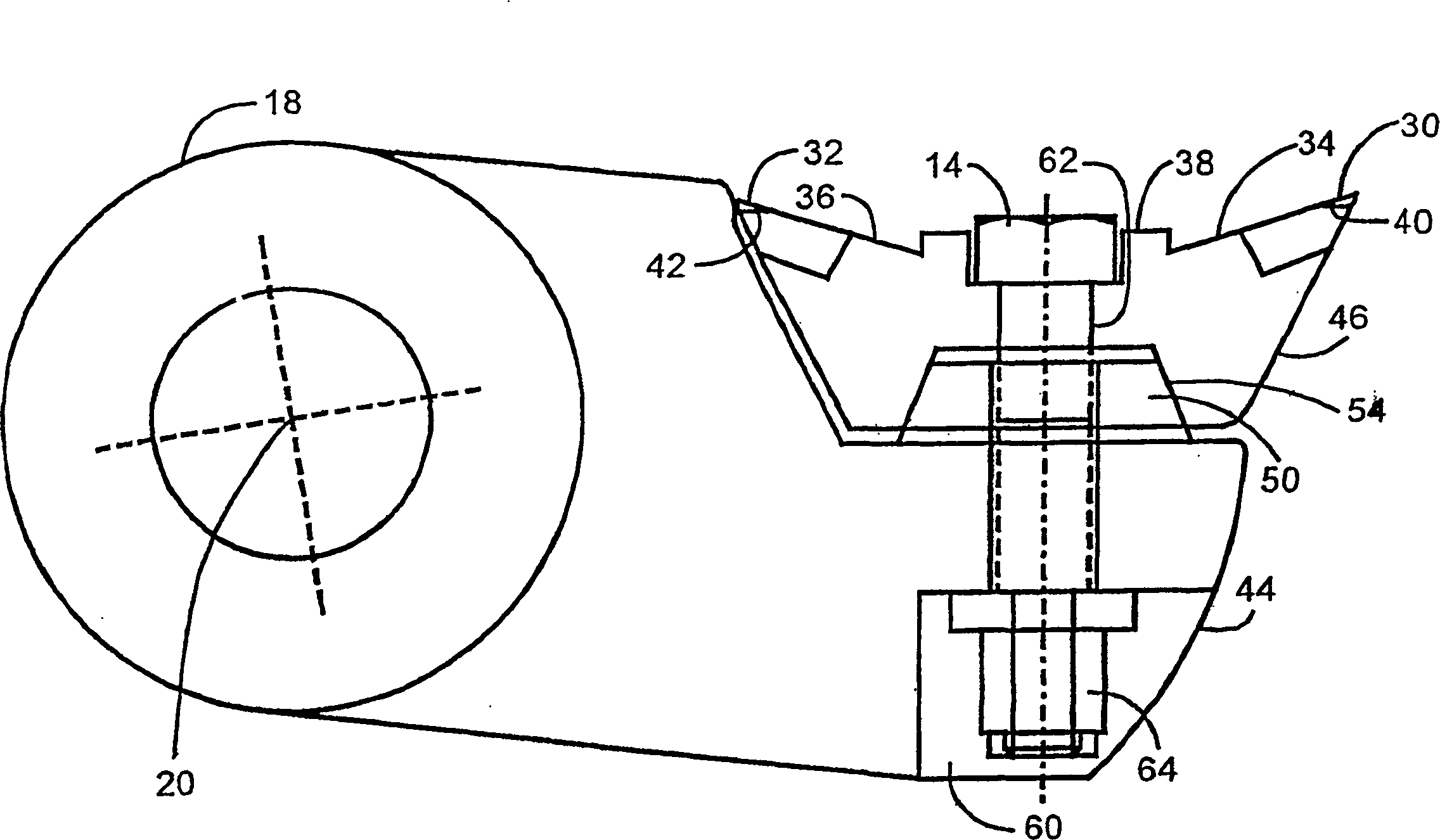

[0017] In Fig. 1, 10 represents a rotary hammer. Rotary hammer 10 comprises a main body 12 and a cutter body 16 screwed thereto by means of a bolt 14, which forms the hammer head. The main body 12 includes a hollow cylinder 18 rotatably mounted about an axis 20 . A protrusion 22 is provided on the hollow cylinder. The protrusion 22 is formed substantially as a step, wherein the "step" has a surface 24 on which the body 16 rests. Surface 24 points in the direction of rotation indicated by an arrow 26 in FIG. 1 . It thus forms the front surface of the body 12 . The knife body 16 is positively seated on the main body 12 . Due to the stepped structure, the cutter body 16 is surrounded on both sides by the main body 12 and forms a unit with it, with no possibility of cutting material getting in between.

[0018] The cutter body 16 has the same trapezoidal cross-section over its entire width. The smaller parallel face 26 of the trapezoid forms the back of the body 16 adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com