Anti-polarizing mode chromatic dispersion (PMD), system

A pulley, radius technology, applied in the field of anti-PMD system, can solve the problem of high fiber PMD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

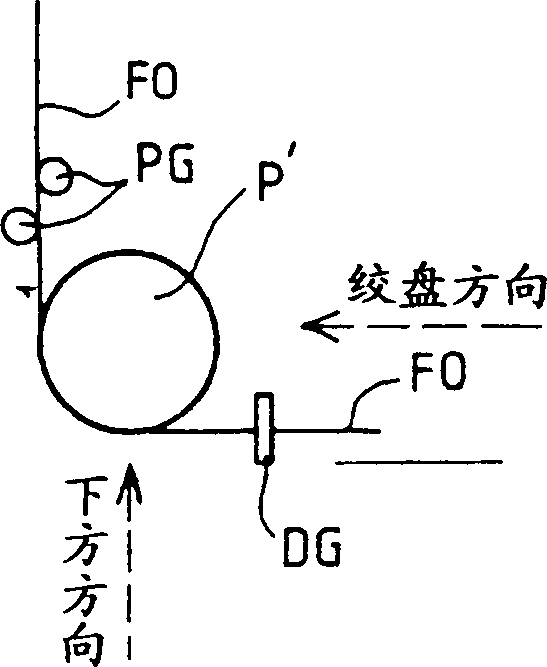

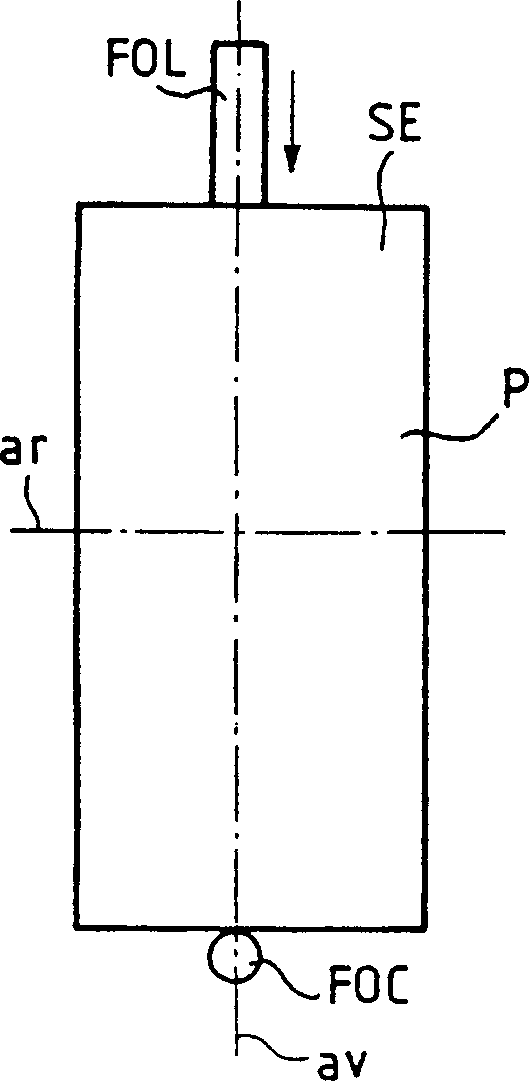

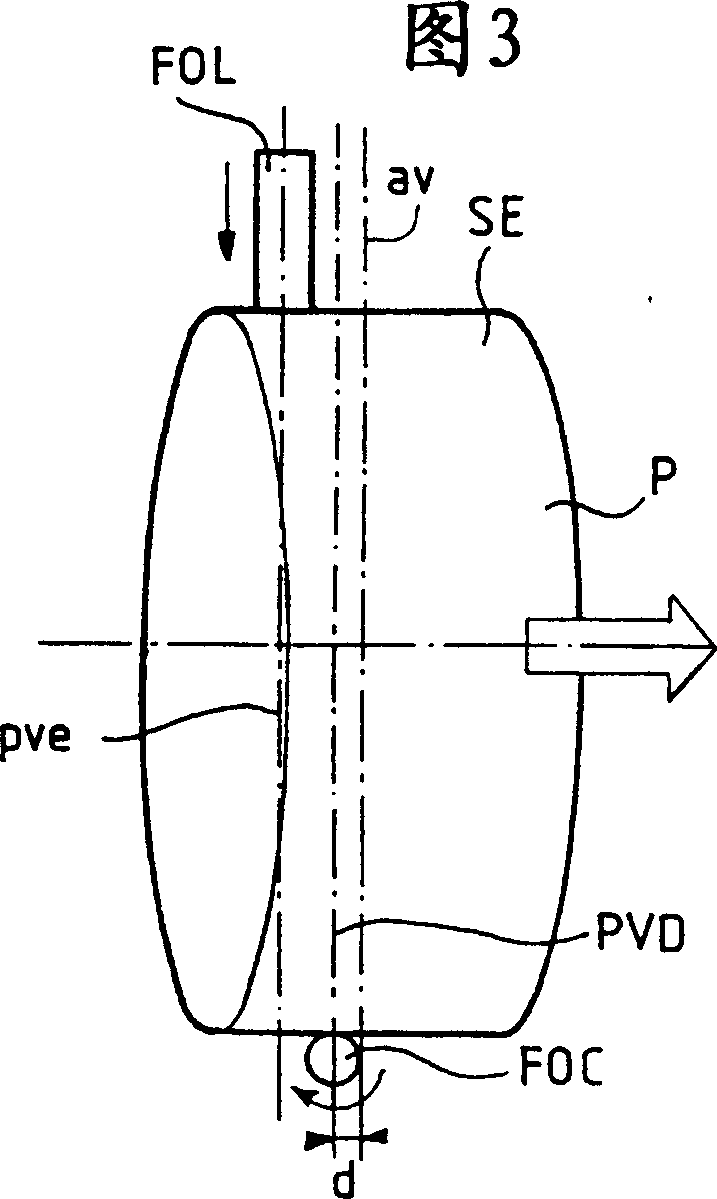

[0010] figure 1 is a schematic illustration of a section of an optical fiber drawing system starting from a preform in which an anti-PMD system according to the present invention is incorporated. figure 1 The section of the fiber drawing system shown is located below the draw tower. The fiber FO coated with two layers of coating moves in the direction indicated by the solid arrow. The optical fiber FO is also guided in vertical movement by guide wheels PG. Subsequently, the fiber FO changes direction while passing the oscillating pulley P'. At the exit of the oscillating pulley P', the optical fiber FO is guided to move horizontally by the guide shaft (guide finger) DG. For simplicity, figure 1 A winch, not shown in , is located behind (downstream) the guide shaft DG. Dashed arrows indicate different viewing directions taken in subsequent views.

[0011] During the fiber drawing process, the different manufacturing stages of the fiber have a significant impact on the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com