Injection molding device and member used thereof and surface treatment method

An injection molding device and component technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of protrusions, incorporation, and poor molding quality of molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

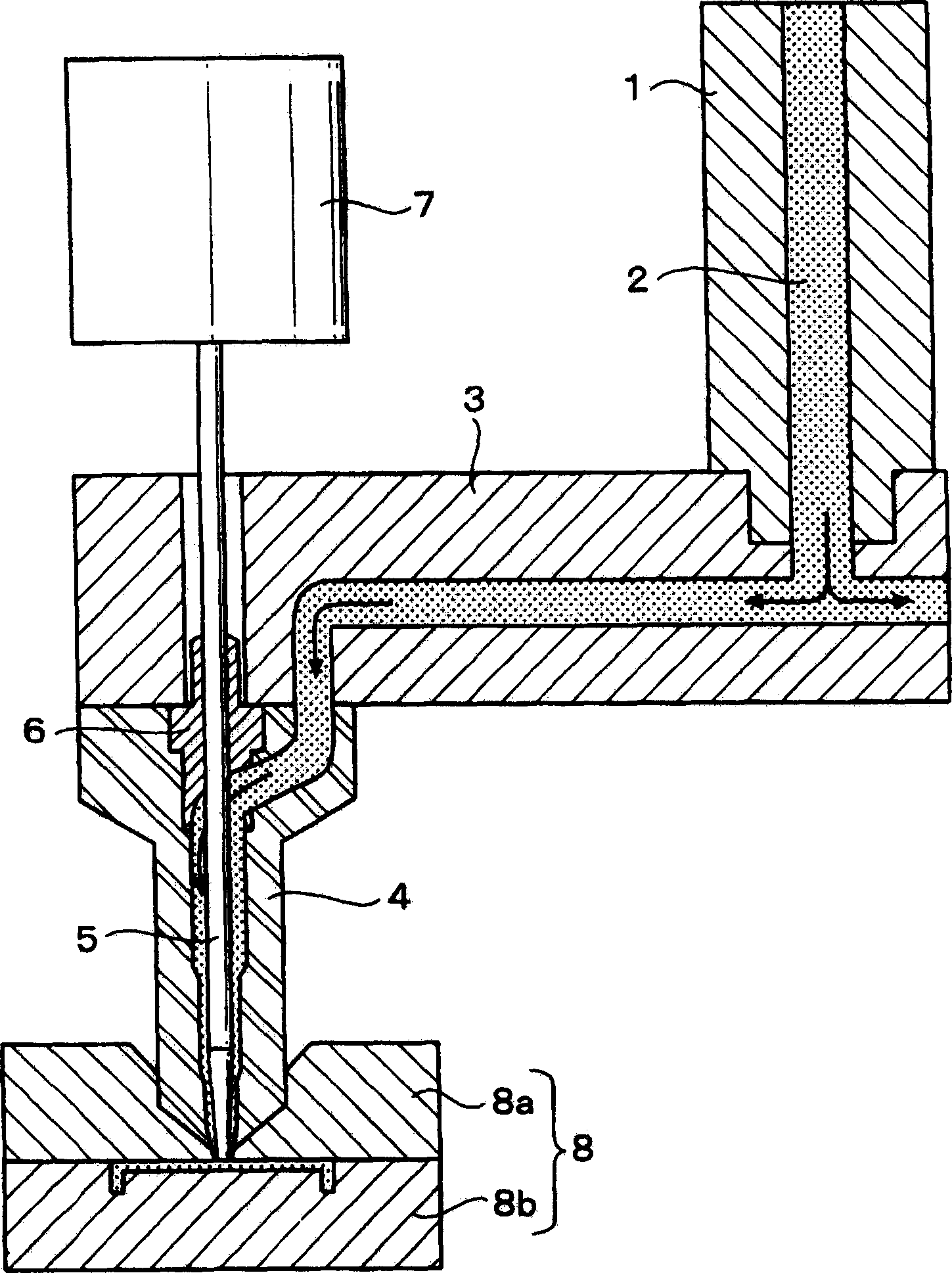

[0040] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is an explanatory drawing of the injection part of the injection molding apparatus of 1st Embodiment.

[0041] 1 in the figure is a gate for supplying molten resin 2 such as ABS resin to the manifold 3, and 4 is a plurality of nozzle bodies installed at the front end of the manifold 3 ( figure 1 Only one nozzle main body 4) is drawn, 5 is a movable injection needle for sealing resin disposed in the nozzle main body 4, 6 is an injection needle guide bush that holds the injection needle 5 at the center of the nozzle main body 4, and 7 is a built-in drive The cylinder of the piston for the injection needle 5, 8 is a molding die, and consists of a fixed side die 8a and a movable side die 8b.

[0042] The molten resin 2 supplied from the gate 1 is divided into the direction of each mold 8 along the manifold 3, and is injected into the mold 8 (cavity) from the fron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com