Acidifying unblocking liquid for unblocking stratum of water injection well

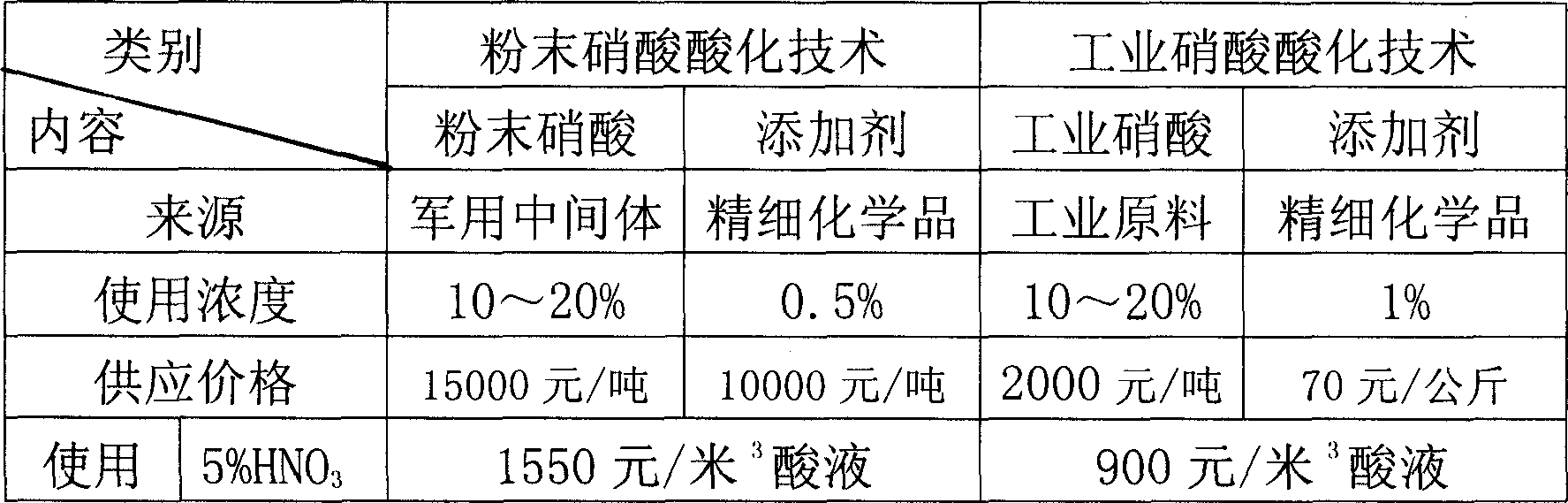

A technology for water injection wells and formations, applied to drilling equipment, etc., can solve the problems of high effective concentration of nitric acid, low cost, slow corrosion of oil pipes, etc., achieve high effective concentration of nitric acid, excellent corrosion inhibition performance, and ensure construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

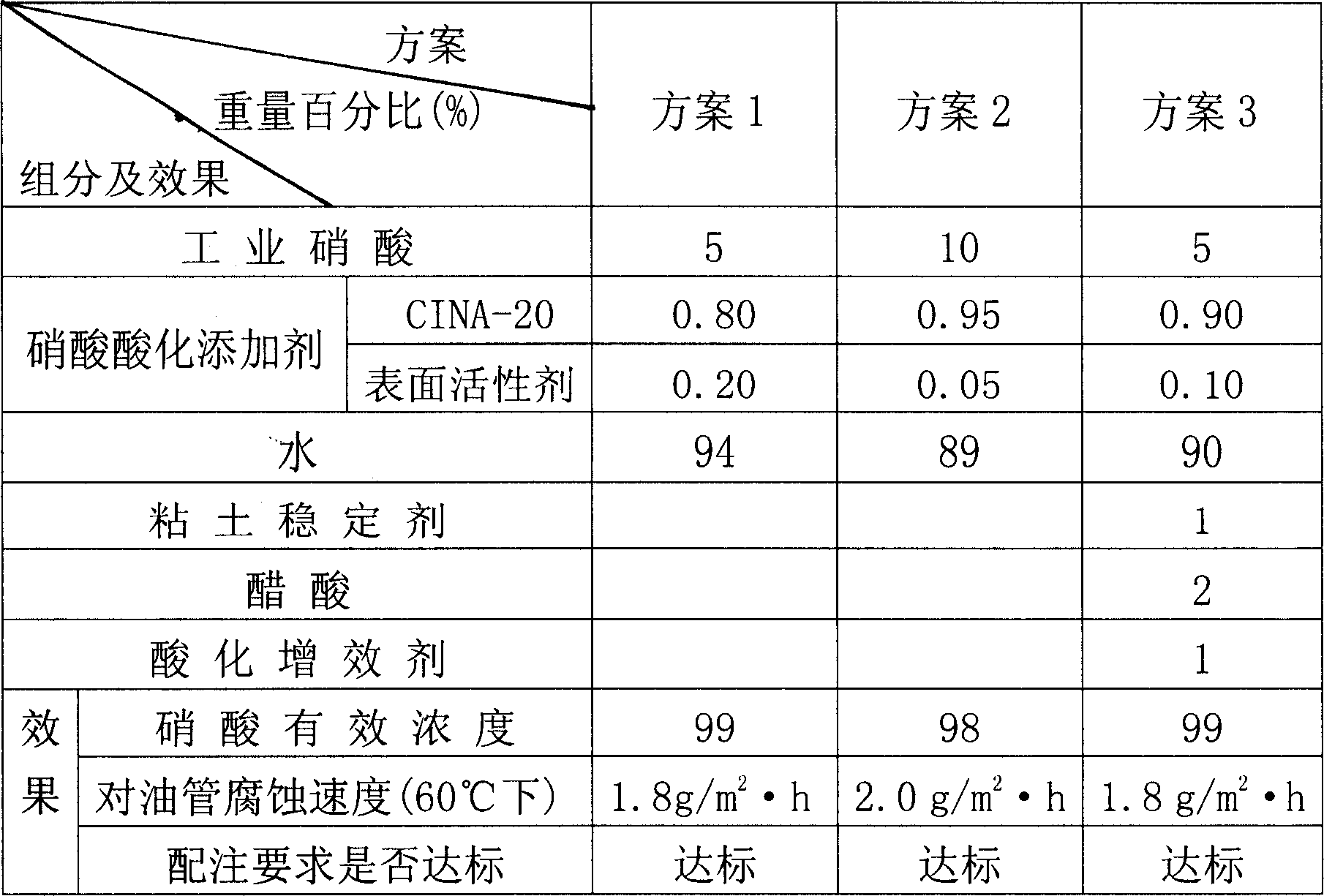

[0025] Example 1. Well Pu 66-79 is a water injection well of the No. 7 Oil Production Plant of Daqing Oilfield Company. Under the water injection pressure of 15.5MPa, Pu 17 2 The water absorption of the layer is 1 meter 3 / day, less than 10 meters 3 / Day's allotment requirements to decide on Luso 17 2 The nitric acid acidification technology is used to remove the blockage and increase the injection in the layer and below layers, and the nitric acid acidification solution prepared in the scheme 1 in the above table 3 is used, and the nitric acid acidification solution is squeezed into 6 meters 3 , and then squeezed into 12 meters of soil acid acidification solution composed of 13.5% HCL+1.5% HF+ additives 3 . After acidification, under the water injection pressure of 13.7Mpa, Pu 17 2 The water absorption of the layer is 13 meters 3 / day, up to 10 meters 3 / day dispensing required, valid for up to 8 months.

Embodiment 2

[0026] Example 2. Well Pu 10-6-G56 is a water injection well of the No. 7 Oil Production Plant of Daqing Oilfield Company. The wellhead pressure is 13.5Mpa. Well Pu 10-6-G56 has two water injection layers in total. Before acidification, the Pu 17-8 layer The water absorption capacity is 3 meters 3 / day, the water absorption of Pu 110 layer is 18 meters 3 / day, the total water absorption is 21 meters 3 / day, 50 meters away from the distribution requirements 3 / day is still 27 meters short 3 / day, use the nitric acid acidizing fluid prepared in the scheme 2 in the above table 3 to carry out acidizing, plugging removal and increasing injection for the whole well, and squeeze into the nitric acid acidizing fluid for 18 meters 3 , and then squeezed into 17 meters of soil acid acidification solution composed of 13.5% HCL+1.5% HF+ additives 3 , under the water injection pressure of 12.7MPa, the water absorption of Pu 17-8 layer is 25 meters 3 / day, the water absorption of Pu ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com