Inductance element

A technology of inductive elements and metal parts, applied in the improvement field of its shielding structure, can solve the problems of cumbersome operation, complicated installation, low productivity, etc., and achieve the effect of convenient fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Next, an inductance element using the present invention will be described with reference to the drawings.

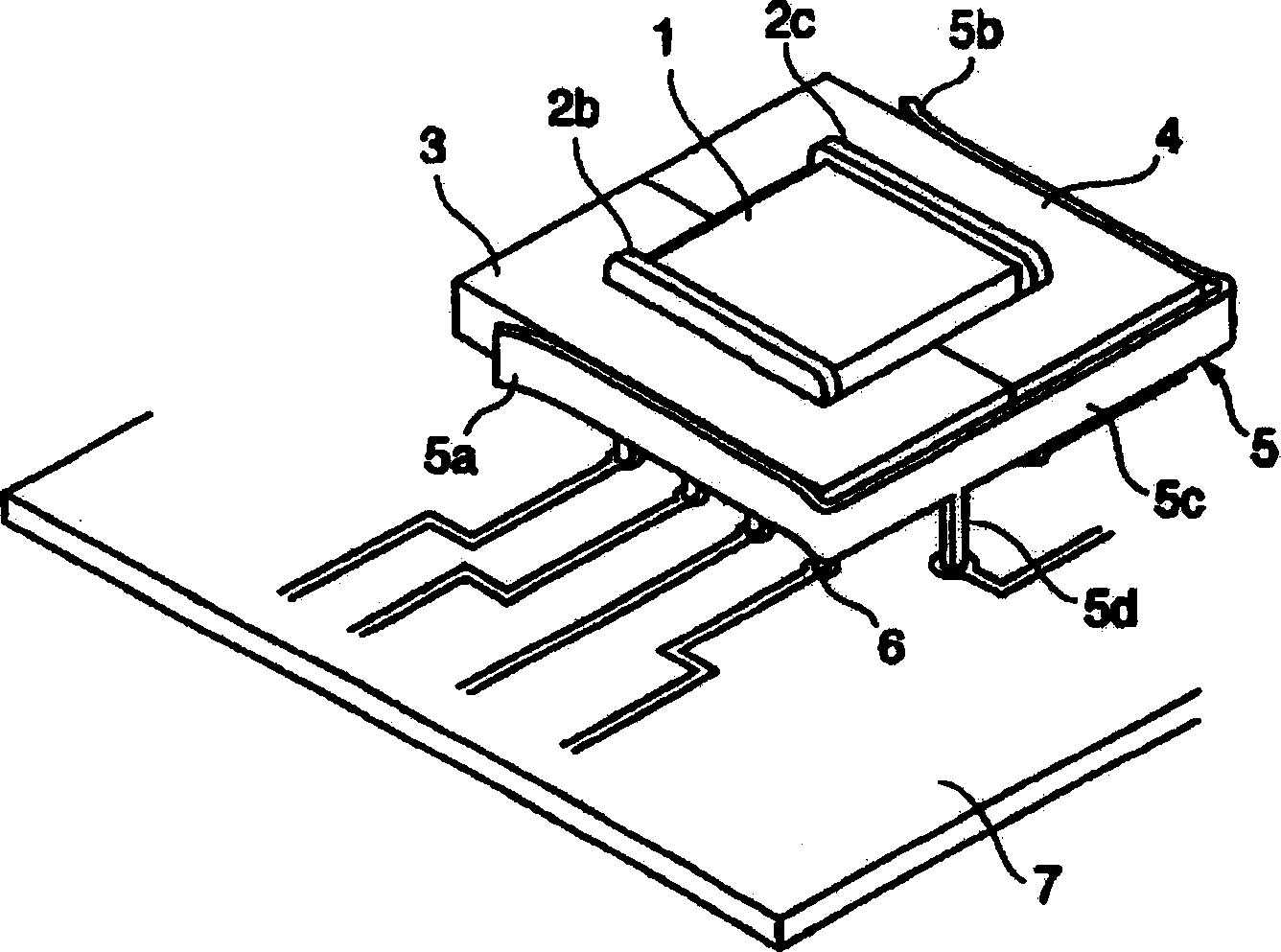

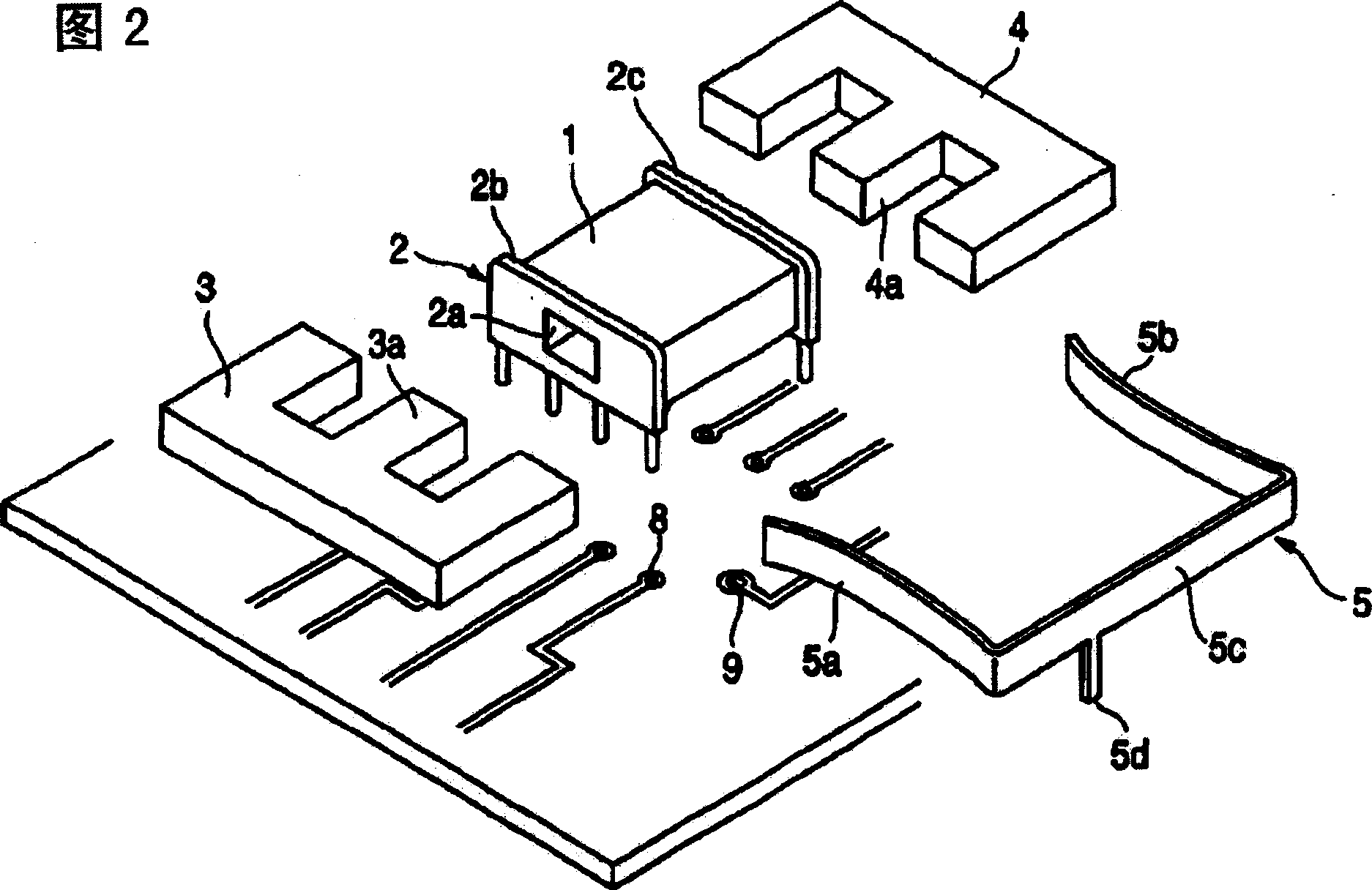

[0015] figure 1 and FIG. 2 is an example of a transformer using the conversion element of the present invention, particularly a transversal magnetic core. figure 1 Fig. 2 shows a situation in which the transformer using the present invention is mounted on a printed circuit board, and Fig. 2 shows a situation in which the transformer using the present invention is disassembled.

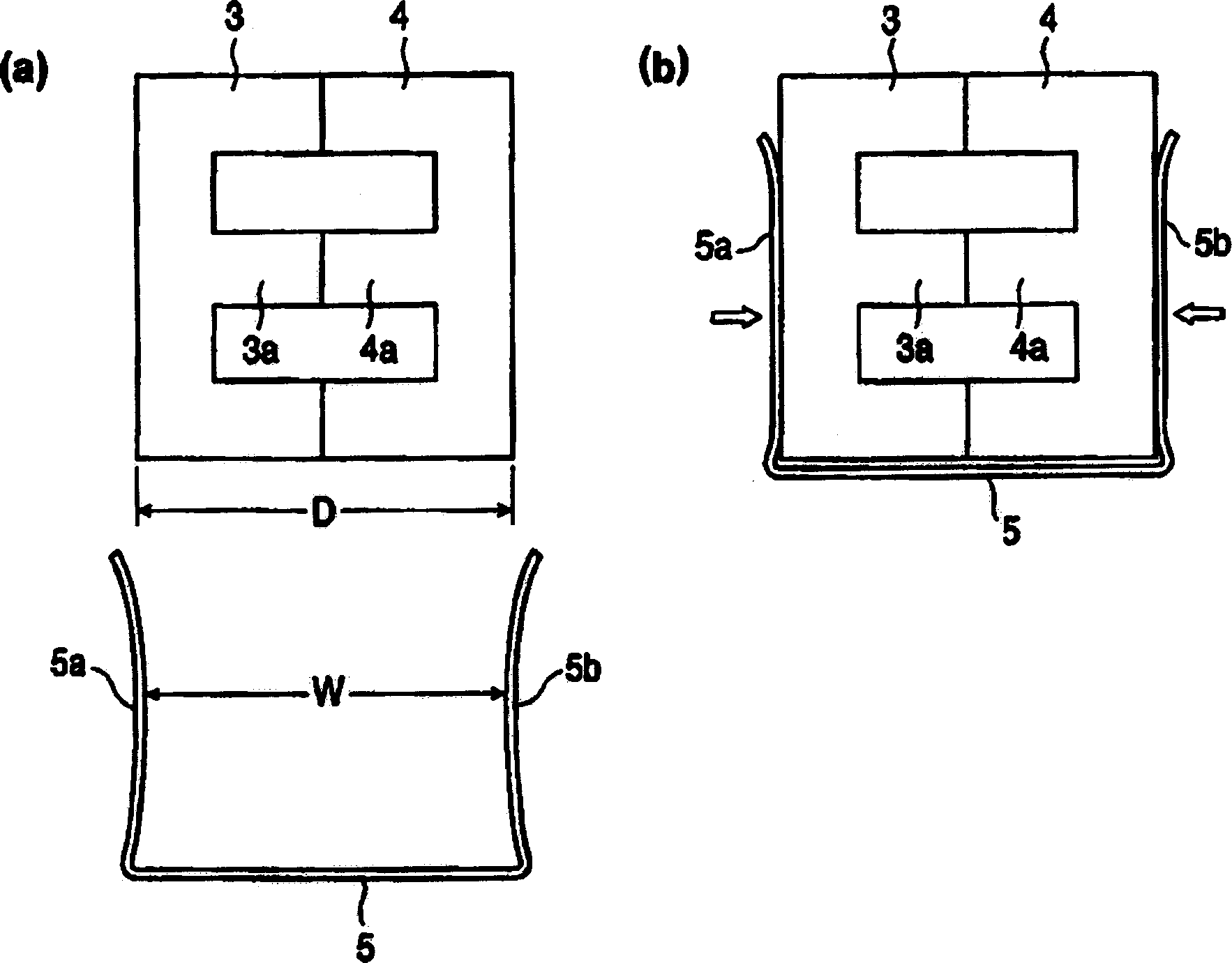

[0016] The transformer of this embodiment is composed of a coil bobbin 2, a pair of iron cores 3, 4 and a fixed metal part 5, the coil bobbin 2 is wound with a winding 1 such as a primary coil and a secondary coil, and the iron cores 3, 4 are inserted into the coil bobbin In the coil hole 2a of 2, a fixing metal piece 5 made of metal is used for assembling these iron cores 3, 4.

[0017] The bobbin 2 consists of a molded part, for example of plastic, with flanges 2b, 2c at its ends. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com