Quasi-crystalline hydrated magnesium-aluminium hydroxy carboxylates, their preparation and their use

A technology for hydrating magnesium hydroxycarboxylate and hydrating hydroxycarboxylic acid is applied in the field of preparing magnesium-aluminum solid solution and anionic clay, and can solve the problems of limiting the operating conditions of the preparation method, equipment corrosion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060]The magnesium acetate solution was prepared as follows. To deionized water (1108 g) was added glacial acetic acid (996 g). To this solution, 335 g of MgO (Spectrum Chemical Company; Hoavy USPpower; MA125) was slowly added with stirring until the MgO was completely dissolved, resulting in a solution with a pH of 5.45.

Embodiment 2

[0062] An alumina sol was prepared by adding 50.0 g of Catapal A(R) to a mixture of 3.45 g of glacial acetic acid and 245.0 g of deionized water and mixing in a Waring mixer at high speed for 15 minutes. To the resulting mixture was added 103.4 g of the magnesium acetate solution of Example 1. The resulting mixture was mixed in a mixer for 20 minutes to obtain a gel having a pH of 5.53 and a Mg / Al molar ratio of 0.5. The gel was aged at 80°C for 27 hours in a closed container. The product was dried in an oven at 100°C overnight and ground to a fine powder.

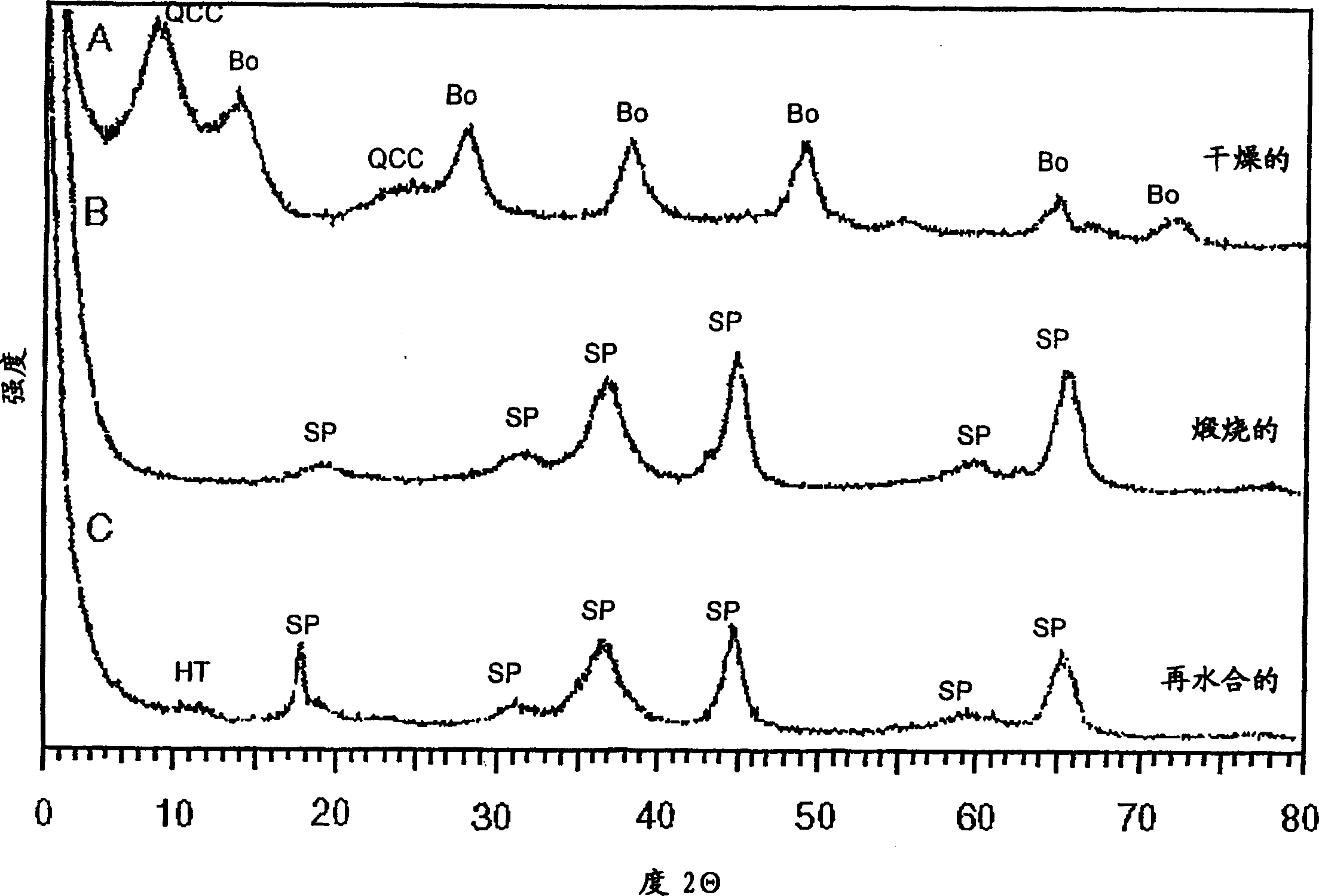

[0063] figure 1 The PXRD pattern of the sample obtained by using CuK-α rays with a wavelength of 1.5418 Å is shown. The spectrum contains the characteristic reflection of unreacted pseudoboehmite and two reflections of the QCC at about 9° and 24° 2Θ, corresponding to intervals of about 11.1 and 3.7 Å. The reflection of the pseudo-boehmite phase hides a third QCC reflection near 38° 2θ (2.4 Å). figure 1 Also shown is...

Embodiment 3

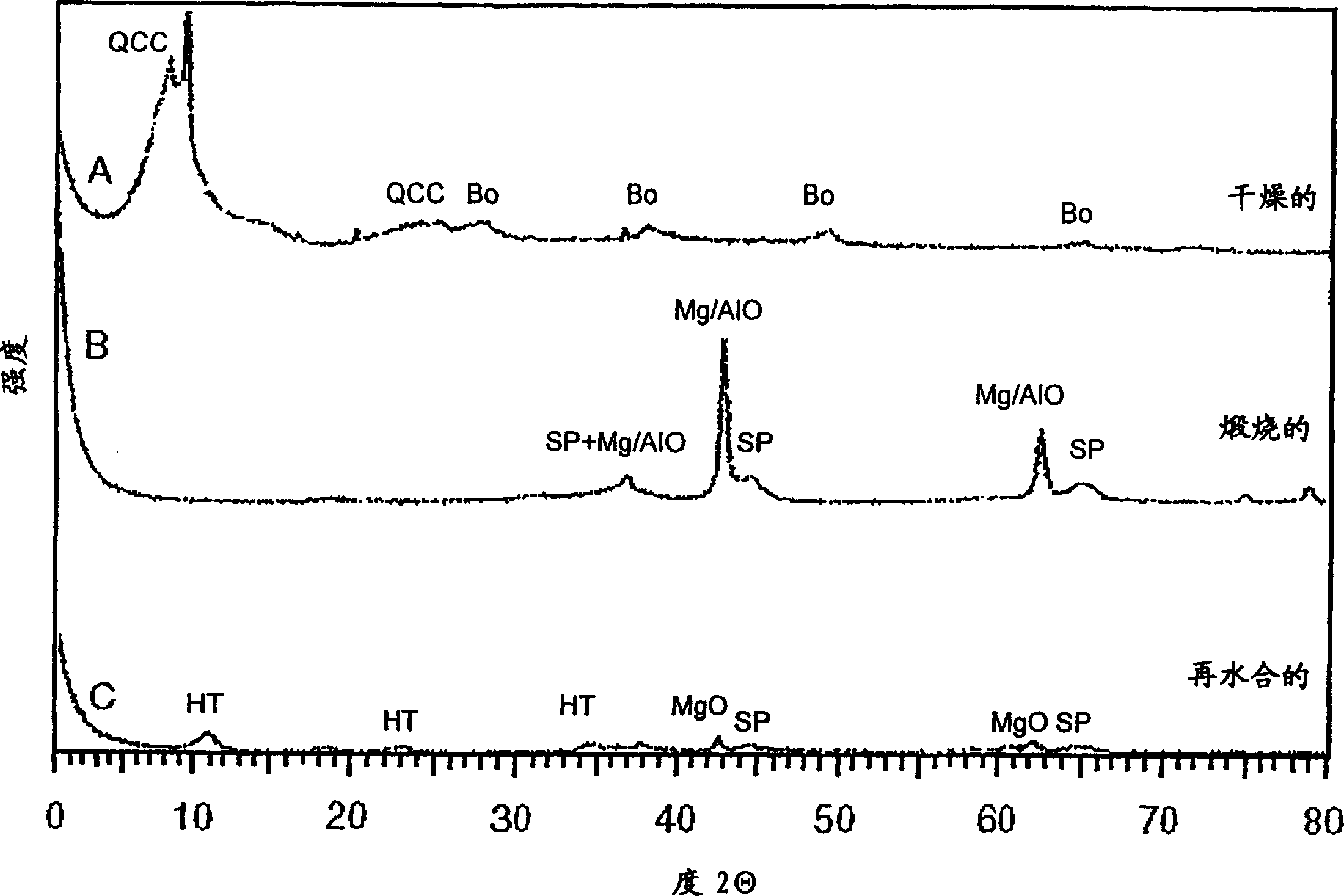

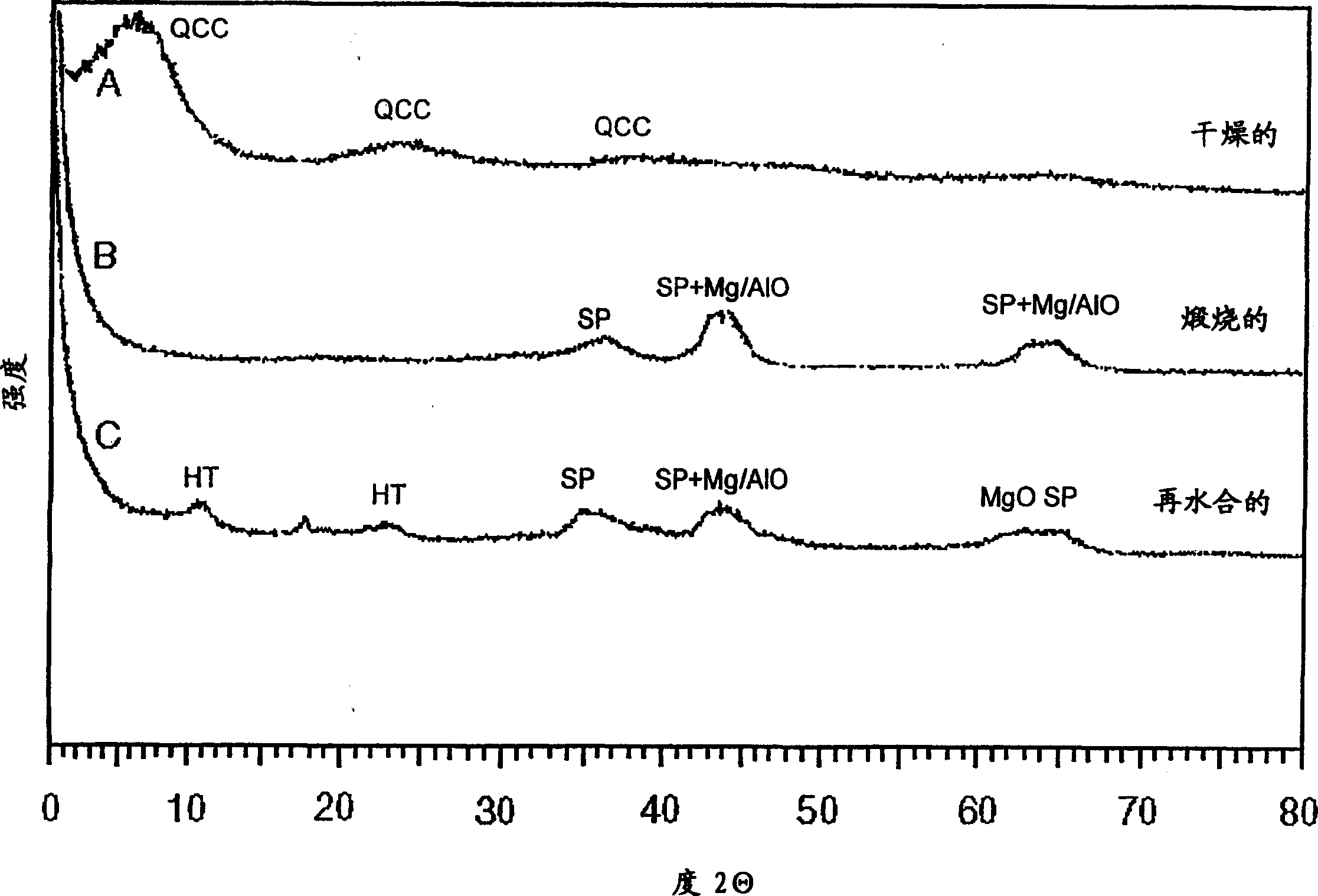

[0065] Example 2 was repeated except that 413.5 g of magnesium acetate solution was used, resulting in a Mg / Al ratio of 2.0. The pH of the gel was 5.45. figure 2 The PXRD pattern of the product is shown. This pattern indicates the formation of QCC and pseudoboehmite. figure 2 Also shown is the PXRD pattern of this sample after calcination at about 732°C and subsequent rehydration. These patterns show that after calcination, both spinel and Mg / Al solid solution are present. By rehydrating the calcined material, the solid solution was transformed into anionic clay, brucite and magnesia.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com