Optical film, diffusion chip, reflection plate, surface light source device and liquid crystal device

An optical film and light incident surface technology, which is applied in the fields of surface light source devices, liquid crystal display devices, reflectors, optical films, and diffusers, and can solve the problems of large scattering, increased cost, and limited thickness of thin surface light source devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

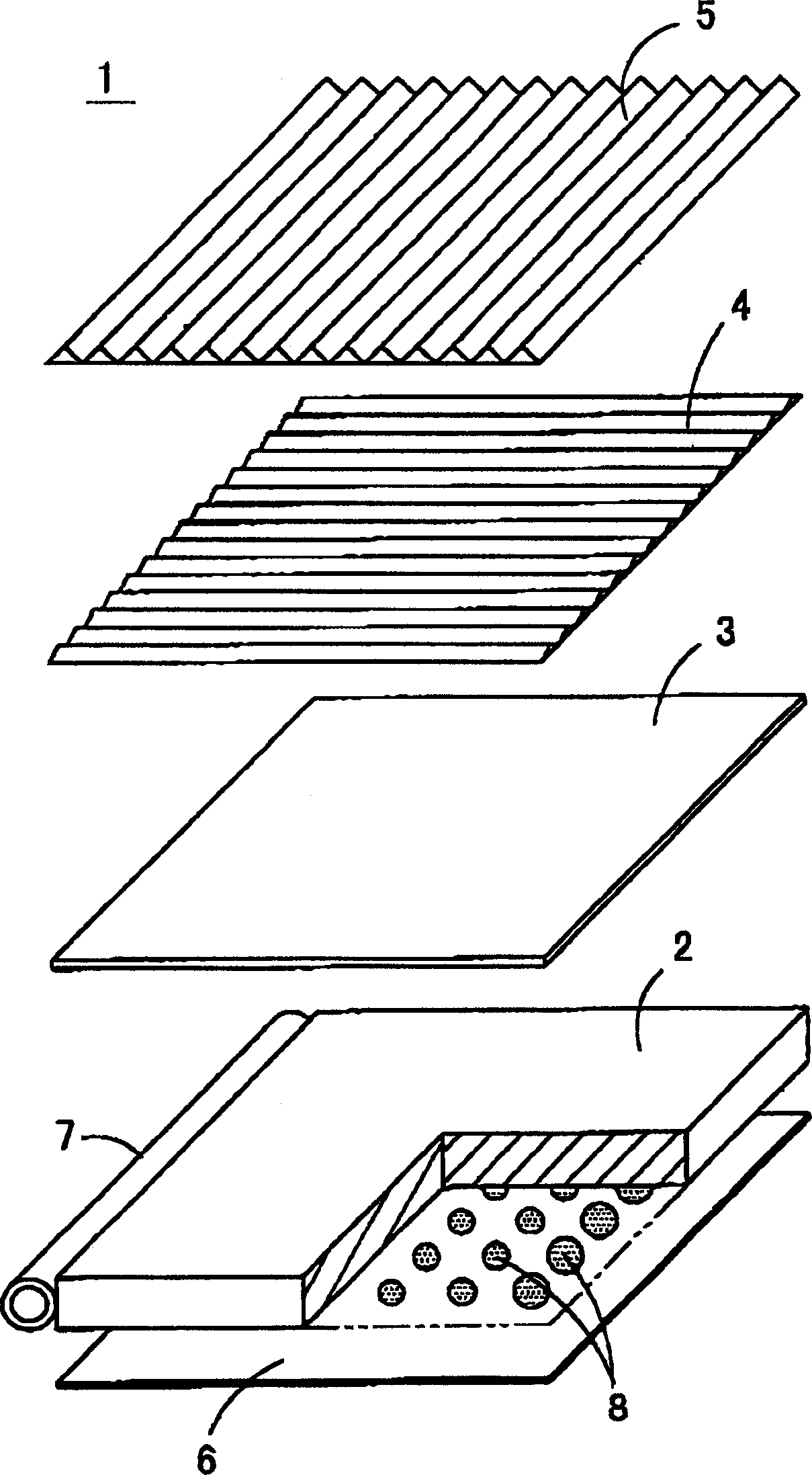

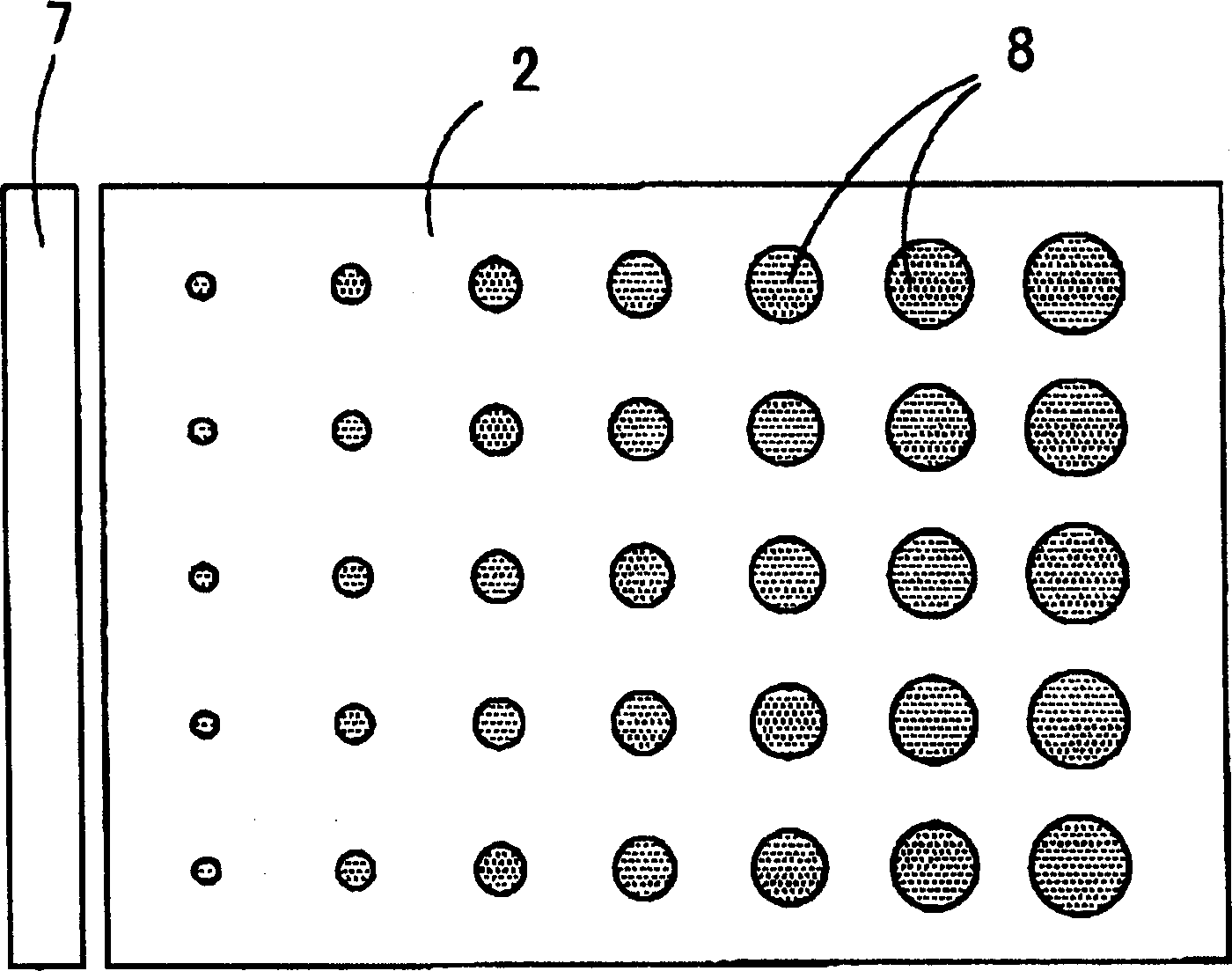

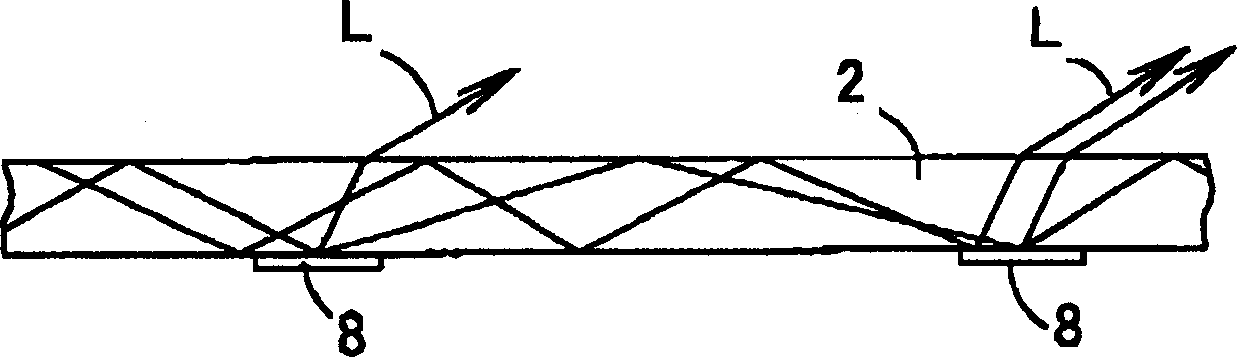

[0052] Picture 10 Is an exploded perspective view of a surface light source device 21 according to an embodiment of the present invention, Picture 11 Is its side view. The surface light source device 21 is composed of a light guide plate 22, an optical film 23 arranged on the upper surface of the light guide plate 22, a reflective plate 24 arranged under the light guide plate 22, and a light source 25 arranged on the side surface of the light guide plate 22. The light source 25 can be a light emitting diode (LED), a cold cathode ray tube, an electroluminescence (EL), etc. The light guide plate 22 is formed of a transparent resin or glass material with high refractive index such as methacrylic resin or polycarbonate resin as a flat plate. In the lower surface of the light guide plate 22, minute concave-convex patterns 26 with circular or triangular cross-sections are formed, and the distribution density of the concave-convex patterns 26 gradually increases as it moves away from ...

no. 2 approach

[0071] Figure 18 It is an exploded perspective view of a surface light source device 41 according to another embodiment of the present invention. In this surface light source device 41, an optical film 42 and a prism sheet 43 are stacked on the light guide plate 22.

[0072] The prisms 27 formed on the upper surface of the optical film 42 are in one direction, but they do not extend over the entire width of the optical film 42 but are appropriately divided and arranged on the upper surface of the optical film 42. In addition, the size of the prism 27 is not uniform, but is formed into a random size.

[0073] The diffusion patterns 28 arranged under the optical film 42 are also in the same direction. Each diffusion pattern 28 can extend over the entire width of the optical film 42, and each diffusion pattern 28 can also be appropriately divided and arranged under the optical film 42. . In addition, the diffusion patterns 28 are also formed in random sizes, but have shapes that ar...

no. 3 approach

[0077] Fig. 19(a) is a partial plan view of an optical film 45 according to still another embodiment of the present invention, Fig. 19(b) is a X1-X1 sectional view in Fig. 19(a), and Fig. 19(c) is a back view thereof , Fig. 19(d) is a cross-sectional view of X2-X2 in Fig. 19(c). The optical film 45 can be used for example Figure 18 Such a surface light source device is shown. Similarly, the prism 27 on the upper surface of the optical film 45 is appropriately divided and arranged. In addition, the size of the prism 27 is not uniform, but is formed into a random size. Furthermore, in the optical film 45, each prism 27 is divided into a tortoise shell shape, and the degree of randomness is very high.

[0078] The diffusion pattern 28 provided under the optical film 45 is also divided into tortoiseshell-shaped regions and arranged at a high degree of randomness. Furthermore, in this optical film 45, as shown in FIG. 19(b), the diffusion pattern 28 is composed of the main inclined su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com