Pressure device and method

A technology of applying pressure and vacuum pressure, applied in the vacuum pressure device and the pressure field, can solve the problems of large-scale device, large-scale high cost, high cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

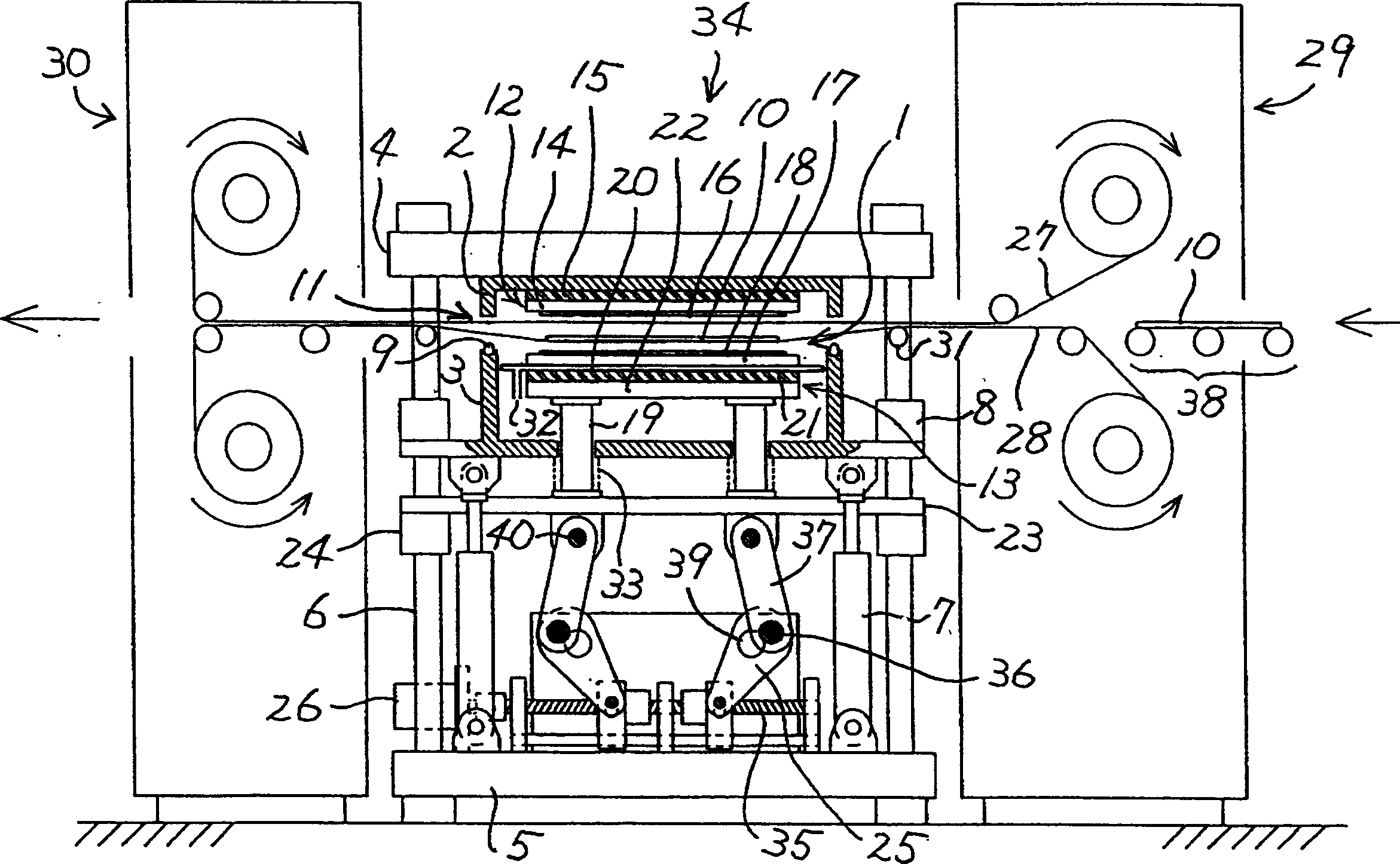

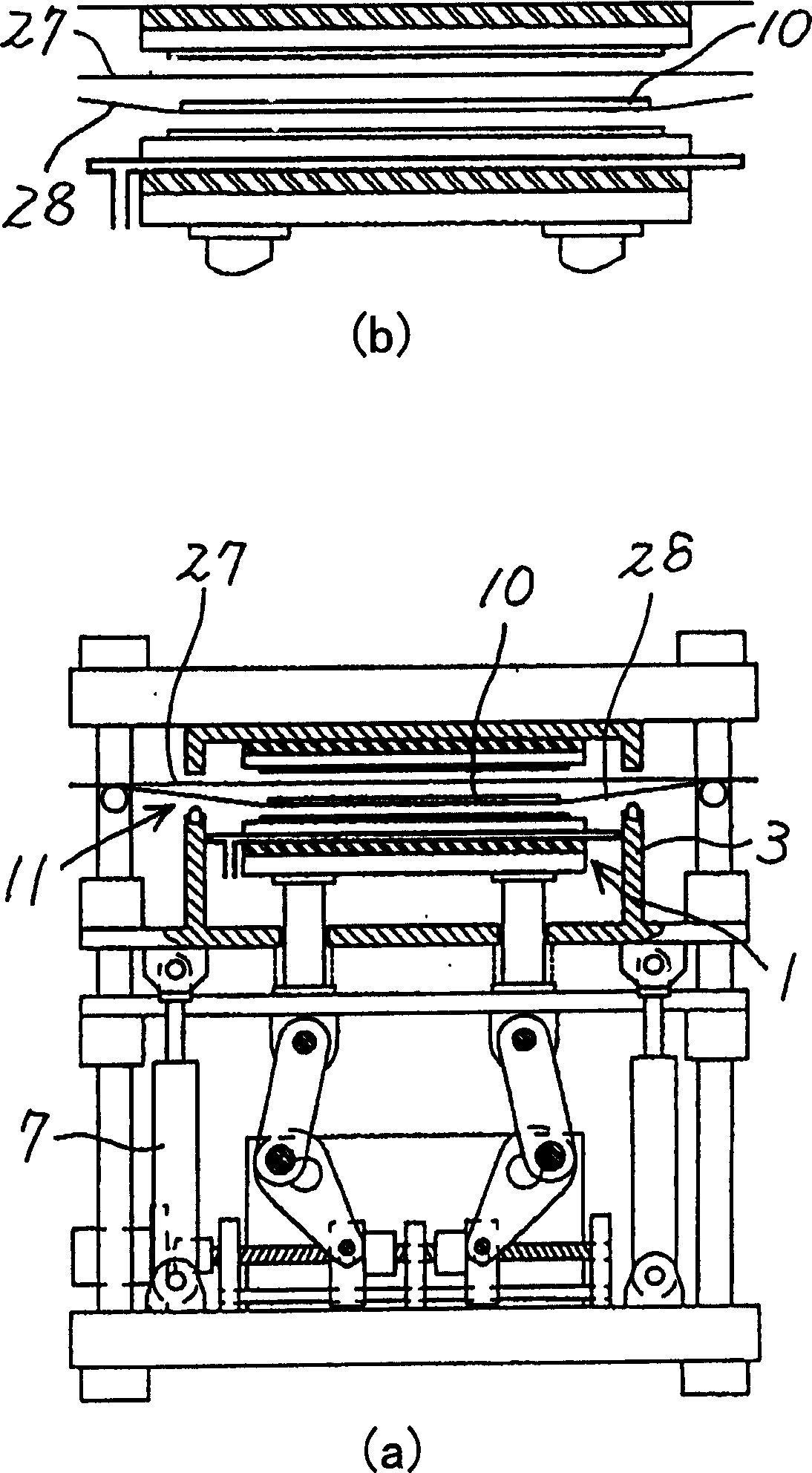

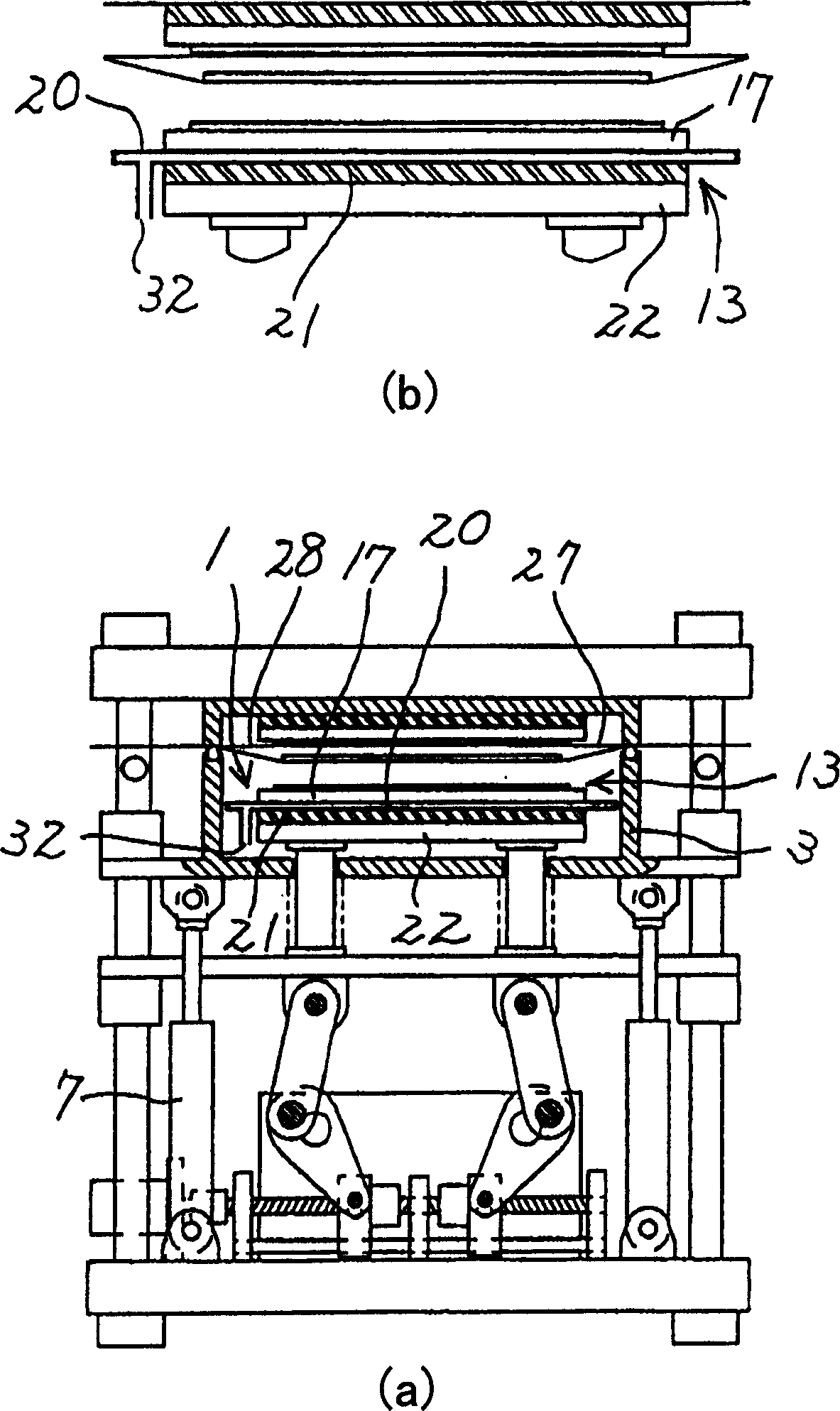

[0042] figure 1 It is a partially cutaway side view showing a vacuum pressure device according to an embodiment of the present invention.

[0043] The vacuum chamber 1 is provided on the vacuum pressure part 34 of the vacuum pressure device. The vacuum chamber 1 is composed of an upper case member 2 and a lower case member 3 .

[0044] The upper housing part 2 is mounted on a support block 4 . In addition, a lower support member 5 as a base is provided on the vacuum pressure part 34, and the support block 4 and the lower support member 5 are connected to each other by a pillar 6 whose upper end is fixed on the support block 4 and whose lower end is fixed on the lower support member 5. connect.

[0045] On the lower surface of the lower case member 3 which is the other member forming the vacuum chamber 1, a driving device 7 such as an air cylinder device is pivotally connected. Furthermore, a guide mechanism 8 for reliably moving the lower case member 3 up and down along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com