Method for preparing silicon-carbon negative electrode of lithium battery through mechanical compounding without firing

A lithium battery, silicon carbon technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of large specific surface area of negative electrode materials, poor electrolyte infiltration effect, complexity, etc., so as to improve the composite ability and reduce the preparation process. , the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

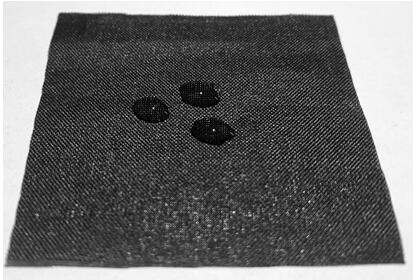

Image

Examples

Embodiment 1

[0025] Step S1, blend nano-silica powder, carbon powder, CMC, SBR styrene-butadiene latex, and deionized water, add to a ball mill and mill for 30 minutes, mix calcium aluminosilicate, carbon black conductive filler, sodium-based bentonite suspending agent, room temperature curing epoxy Put the binder and deionized water into the ball mill, and continue the ball milling for 60 minutes to obtain a slurry mixture; 10 parts of nano silicon powder, 85 parts of carbon powder, 1 part of CMC, 1 part of SBR, and 200 parts of deionized water for the first time, 5 parts of calcium aluminosilicate, 15 parts of carbon black conductive filler, 1 part of sodium bentonite suspending agent, 1 part of normal temperature curing epoxy adhesive, and 30 parts of deionized water are added for the second time.

[0026] Step S2, fully mixing the slurry mixture obtained in step S1 with fatty acid glycerides, adding to a twin-screw extruder for mixing and extruding to obtain a composite slurry. Wherein...

Embodiment 2

[0029] Step S1, blend nano-silica powder, carbon powder, CMC, SBR styrene-butadiene latex, and deionized water, add to a ball mill and mill for 32 minutes, mix calcium aluminosilicate, carbon black conductive filler, sodium-based bentonite suspending agent, room temperature curing epoxy Put the binder and deionized water into the ball mill, and continue the ball milling for 65 minutes to obtain a slurry mixture; 11 parts of nano silicon powder, 87 parts of carbon powder, 1.5 parts of CMC, 1.5 parts of SBR, and 215 parts of deionized water for the first time, 5.2 parts of calcium aluminosilicate, 17 parts of carbon black conductive filler, 1.5 parts of sodium bentonite suspending agent, 2 parts of room temperature curing epoxy adhesive, and 33 parts of deionized water are added for the second time.

[0030] Step S2, fully mixing the slurry mixture obtained in step S1 with fatty acid glycerides, adding to a twin-screw extruder for mixing and extruding to obtain a composite slurry...

Embodiment 3

[0033]Step S1. Blend nano-silica powder, carbon powder, CMC, SBR styrene-butadiene latex, and deionized water, add ball mill and mill for 35 minutes, and mix calcium silicate, carbon fiber powder, sodium-based bentonite suspending agent, and room temperature curing epoxy binder and deionized water into the ball mill, and continue ball milling for 70min to obtain a slurry mixture; 13 parts of nano silicon powder, 88 parts of carbon powder, 2 parts of CMC, 2 parts of SBR, 230 parts of deionized water, 5.5 parts of calcium silicate Parts, 18 parts of carbon fiber powder, 2 parts of sodium bentonite suspending agent, 3 parts of room temperature curing epoxy binder, and 35 parts of deionized water are added for the second time.

[0034] Step S2, fully mixing the slurry mixture obtained in step S1 with fatty acid ethylene glycol ester, adding to a twin-screw extruder for mixing and extruding to obtain a composite slurry. Wherein the slurry mixture is 100 parts, fatty acid glycol est...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com