Combination machine for manufacturing fiber composite thermal insulating material

A thermal insulation material and fiber composite technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as difficult operation, restricted development, waterproof, poor rain and snow resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

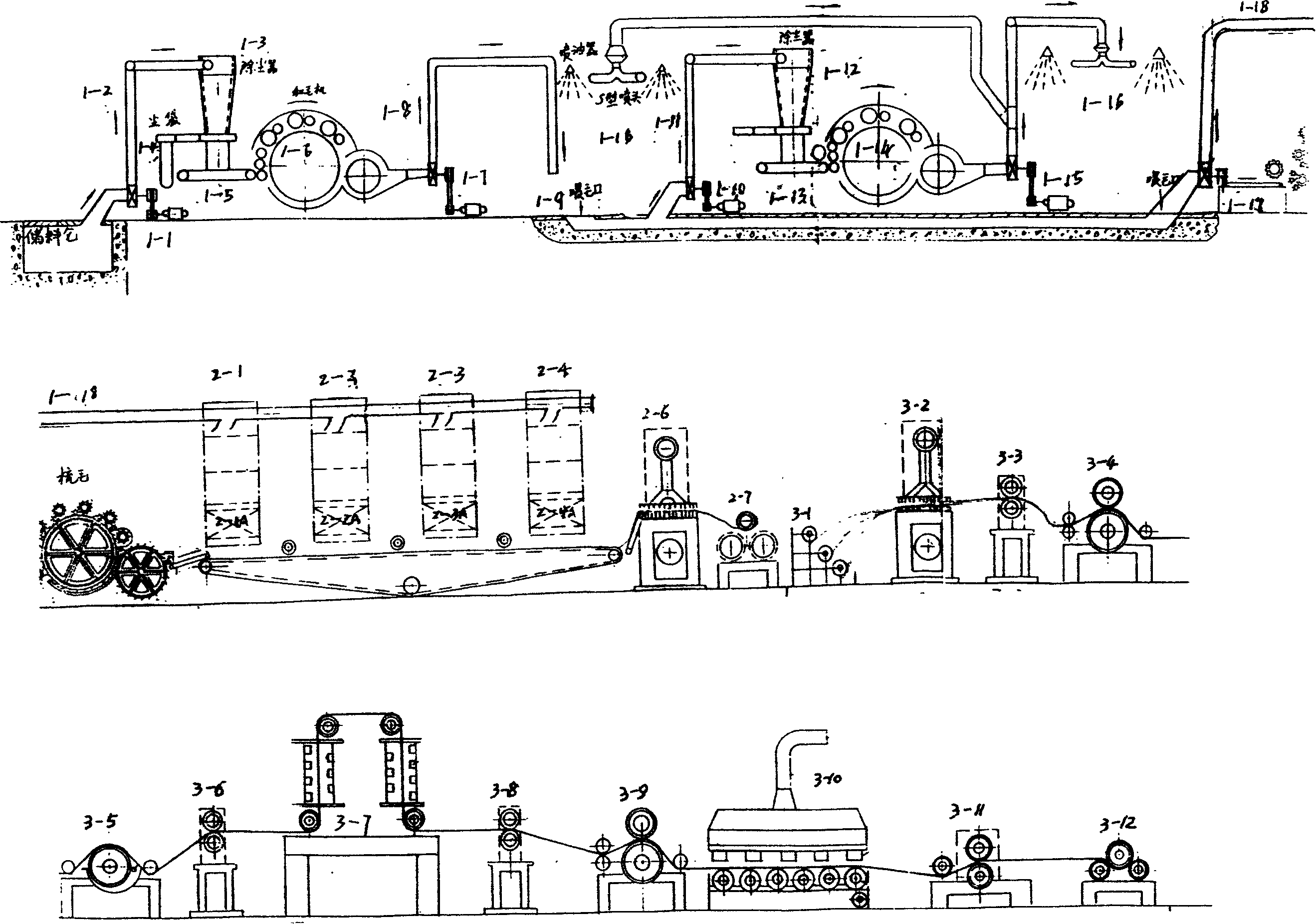

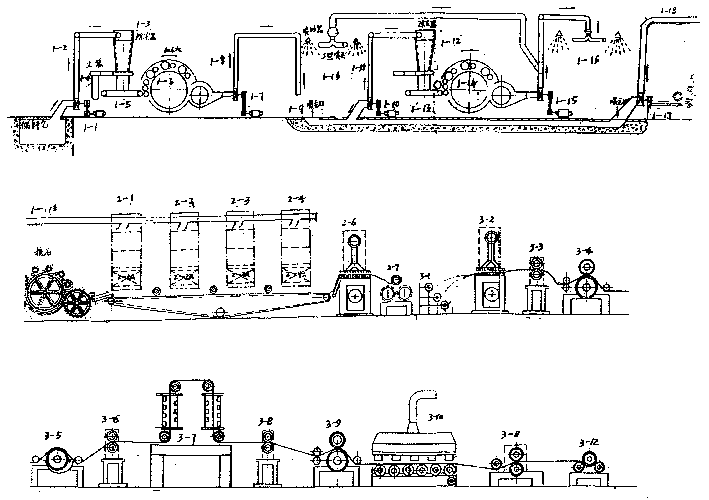

[0023] Each raw material is sucked out from the storage bin, and sent to the dust collector 1-3 through the pipeline 1-2, and the removed raw material enters the wool conveyor 1-5, and the dust enters the dust belt 1-4; After the wool machine 1-5, it is sent to the wool opening machine 1-6, and the raw material after opening is sent to the furrow feeding mouth 1-9 through the pipeline 1-8 through the induced draft fan 1-7, and then passed through the induced draft fan 1 -10 suction, sent to the dust collector 1-12 through the pipeline 1-11, the raw material after dust removal enters the wool closing machine 1-14 through the wool conveying machine 1-13, and the raw material after wool closing passes through the induced draft fan 1-15 , the raw materials are sent to the mixed wool warehouse 1-16A, 1-16B, and processed by adding synthetic crude oil, water, flame retardant, and antistatic agent; the raw materials mixed with oil and water are then sent to the synthetic wool warehous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com