Wire and cable connector assembly and its making process

A technology of cable connectors and electrical connectors, which is applied to the parts, connections, and fixed connections of connection devices, can solve problems such as laborious connections and unreliable connections, and achieve reliability, convenient and reliable connections, and reduce serial connections. The effect of sound interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

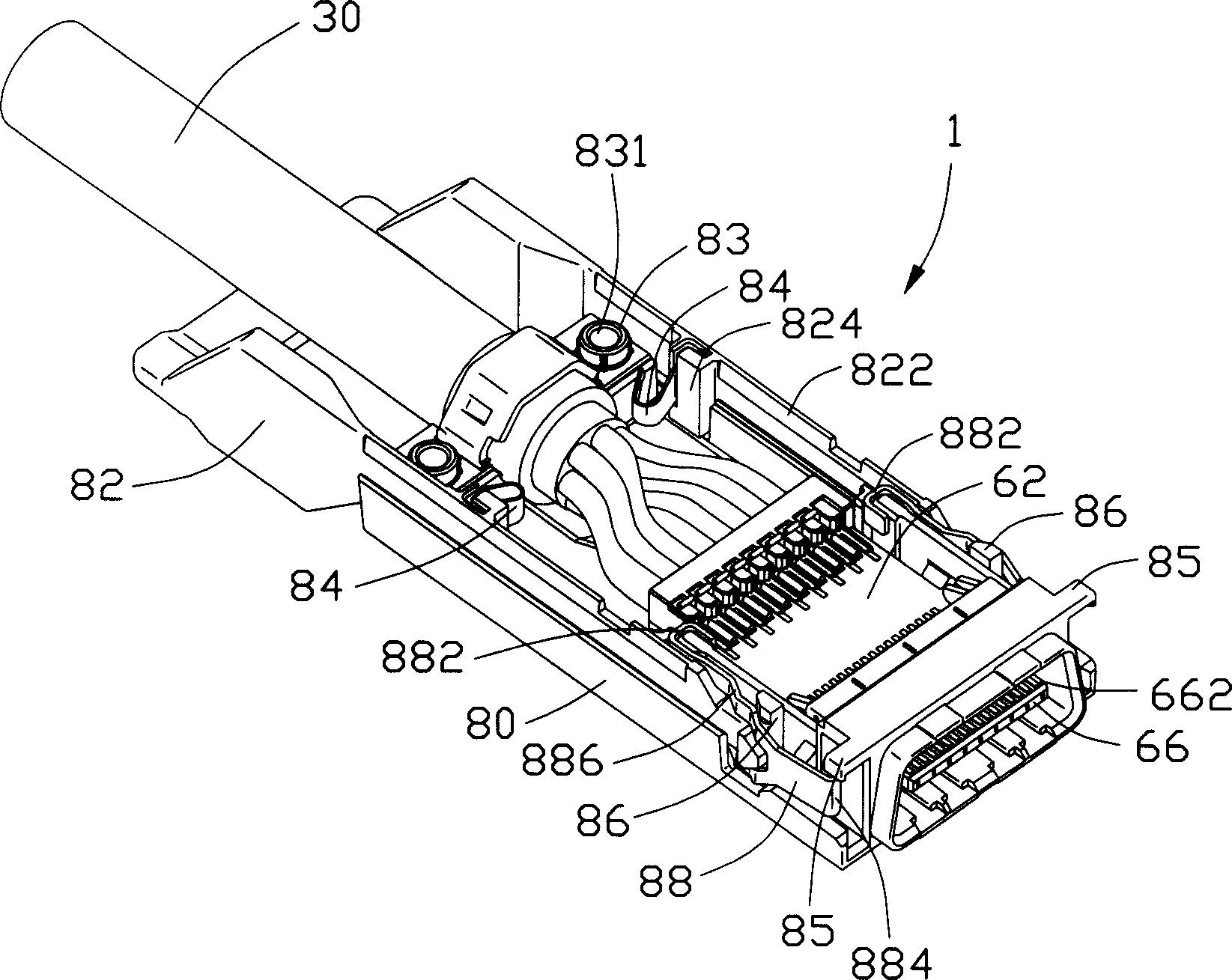

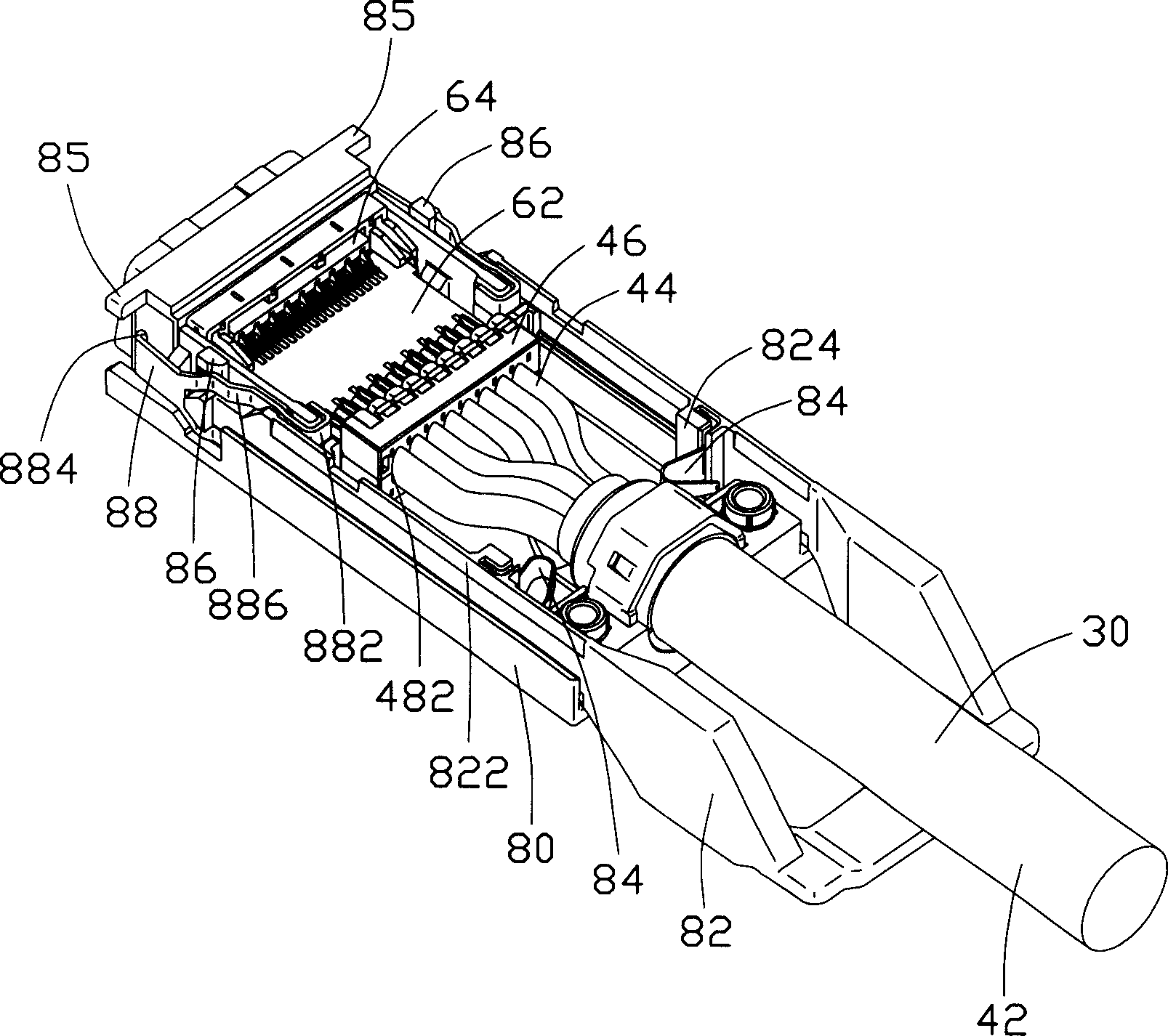

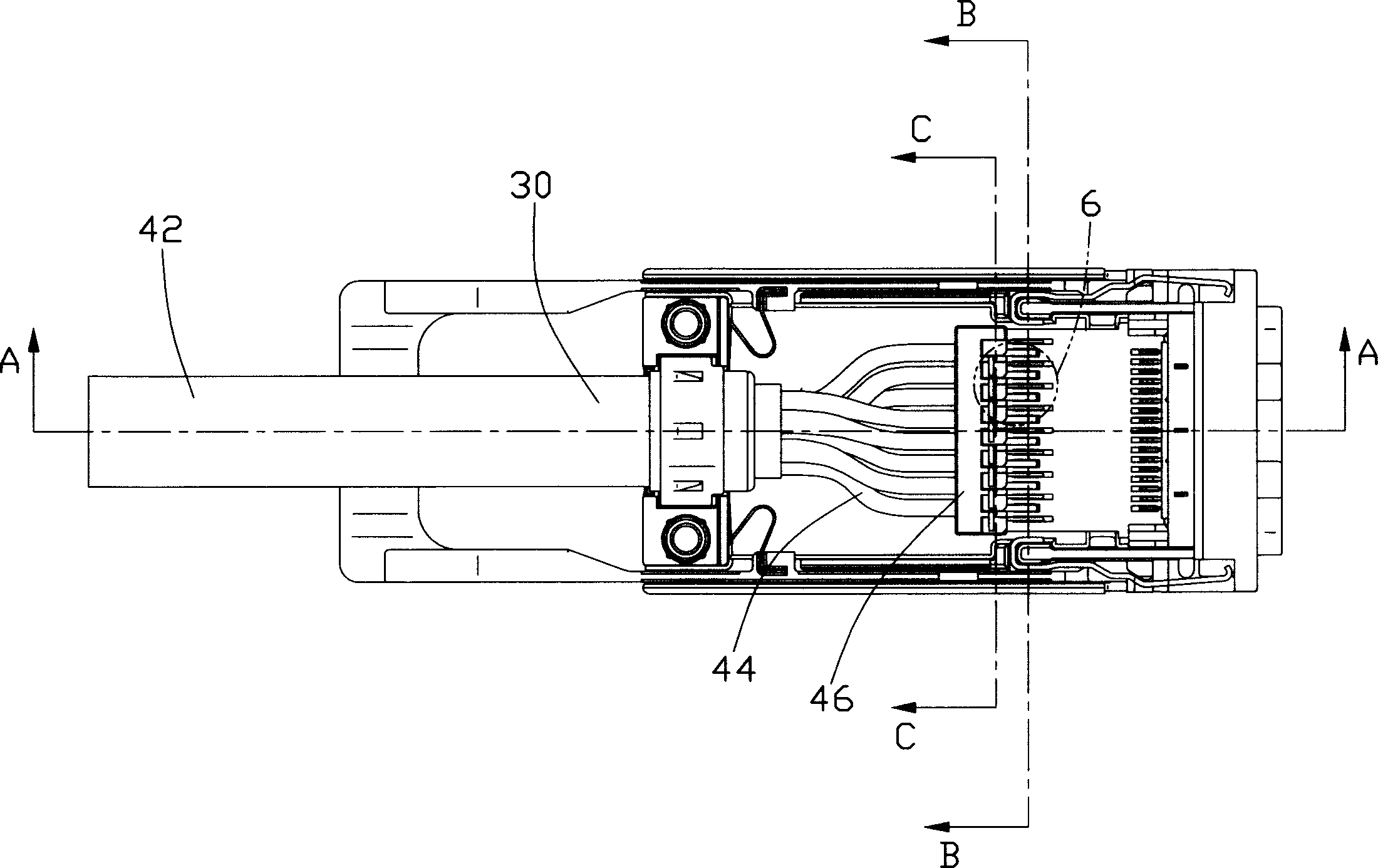

[0024] The cable connector assembly of the present invention will now be described in detail with reference to the accompanying drawings.

[0025] see figure 1 and figure 2 , the cable connector assembly 1 of the present invention is applied in InfiniBand TM field, which includes a covered body 3 (see Figure 4 , Figure 7 and Figure 8 ), the cable connection module 30 and the base 80, wherein the cover 3 and the base 80 are formed by die-casting metal materials such as aluminum alloy. After the cable connection module 30 is put into the base 80, the above-mentioned cover body 3 is provided with screws (not shown) that can be locked into the threaded holes 831 formed on the bolts 83 of the base 80 to connect with the cable connection module 30 and the base 80. Assemble into one. When the cover body 3 is installed on the base 80, the protrusions (not shown) positioned at the front end of the cover body 3 are first positioned respectively under the side edges 85 of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com