Silver halide emulsion with high image contrast, and preparing method and use thereof

A silver halide and emulsion technology, which is applied in the field of printing plate making, can solve the problem of inability to improve the r value of CTP plates, and achieve the effects of high image contrast, improved image contrast, and high image density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

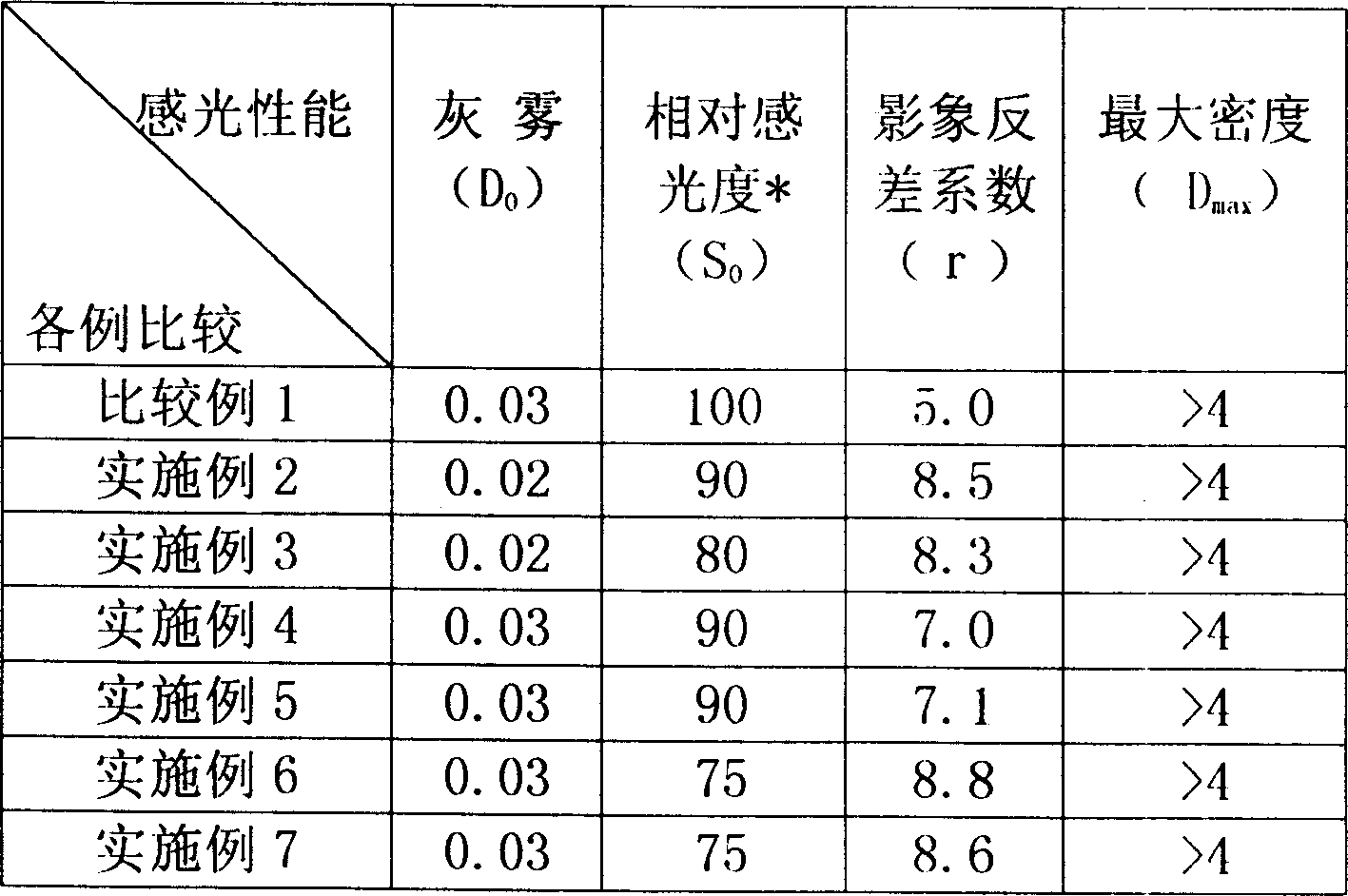

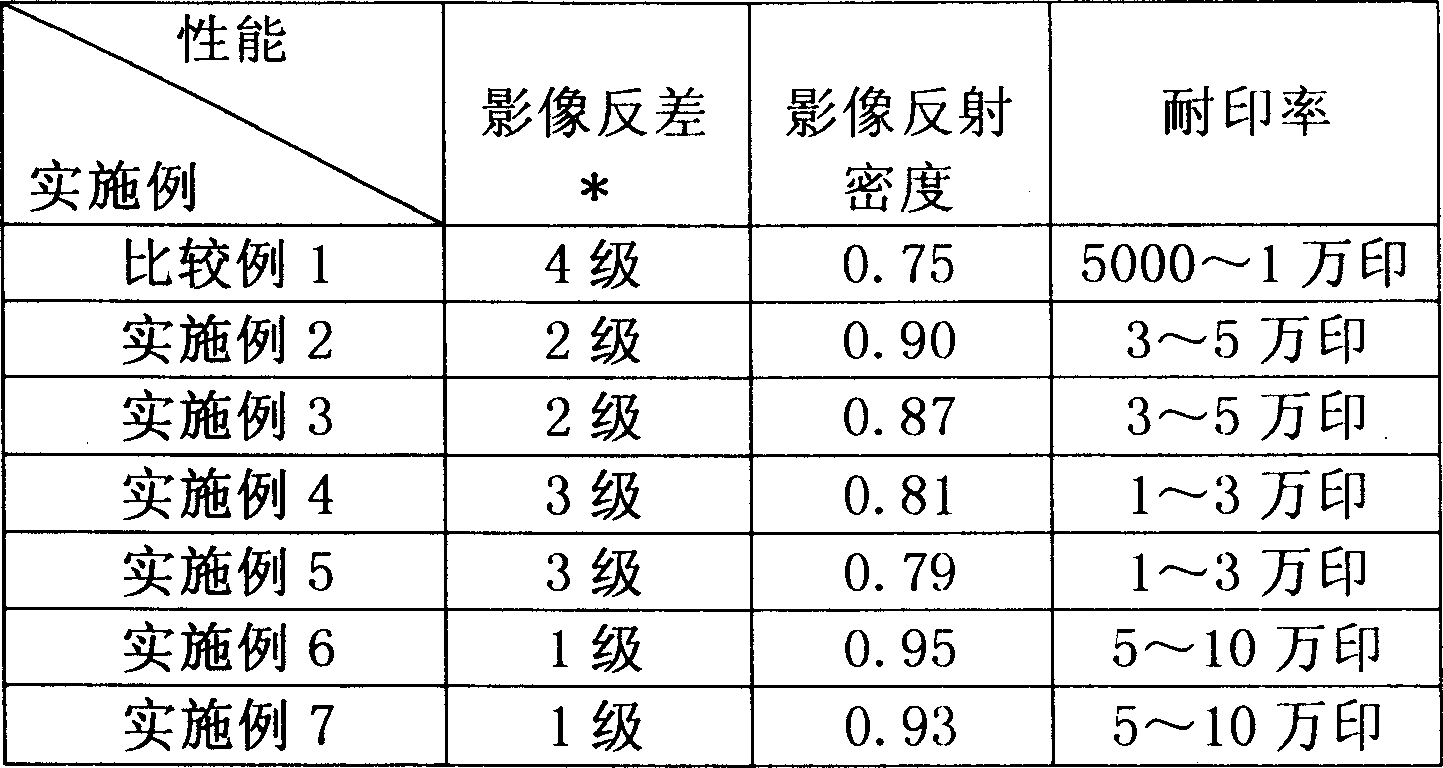

[0068] Adopt the method of comparative example 1, difference is in the emulsification process of step (1), add 1.5 * 10 by every mole silver halide -6 moles of IrCl 4 , other preparation conditions and steps are the same as in Comparative Example 1 to prepare the silver chlorobromide emulsion of the present embodiment, and the emulsion properties are shown in Table 3.

[0069] Using the silver chlorobromide emulsion prepared in this example, a CTP plate and an offset printing plate were prepared and printed according to the method of Comparative Example 1. The printing results are shown in Table 4.

Embodiment 3

[0071] Adopt the method for embodiment 2, difference is: replace 1.9mol / l NaCl solution and 0.1mol / l NaBr solution with 1.95mol / lNaCl solution and 0.05mol / l NaI solution; In step (1) emulsification process, press Add 1.25×10 per mole of silver halide -6 moles of RhCl 3 , without adding 1.5×10 -6 moles of IrCl 4 , other preparation conditions and steps are the same as in Example 2 to prepare the silver chloroiodide emulsion of the present embodiment, and the emulsion properties are shown in Table 3.

[0072] Using the silver chloroiodide emulsion prepared in this example, a CTP plate and an offset printing plate were prepared and printed according to the method in Example 2. The printing results are shown in Table 4.

Embodiment 4

[0074] The method of Comparative Example 1 is adopted, and the difference is that before adding the triazindoleizine stabilizer in the step (2) chemical ripening process, add 1.5 × 10 per mole of silver halide -6 moles of IrCl 4 , other preparation conditions and steps are the same as in Comparative Example 1 to prepare the silver chlorobromide emulsion of the present embodiment, and the emulsion properties are shown in Table 3.

[0075] Using the silver chlorobromide emulsion prepared in this example, a CTP plate and an offset printing plate were prepared and printed according to the method of Comparative Example 1. The printing results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com