Paste anhydrous composition for bleaching and dyeing human keratin fibre

A keratin fiber, anhydrous composition technology, applied in the field of simultaneous bleaching and dyeing, can solve the problems of direct dye stability and storage, difficult to handle, difficult to measure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

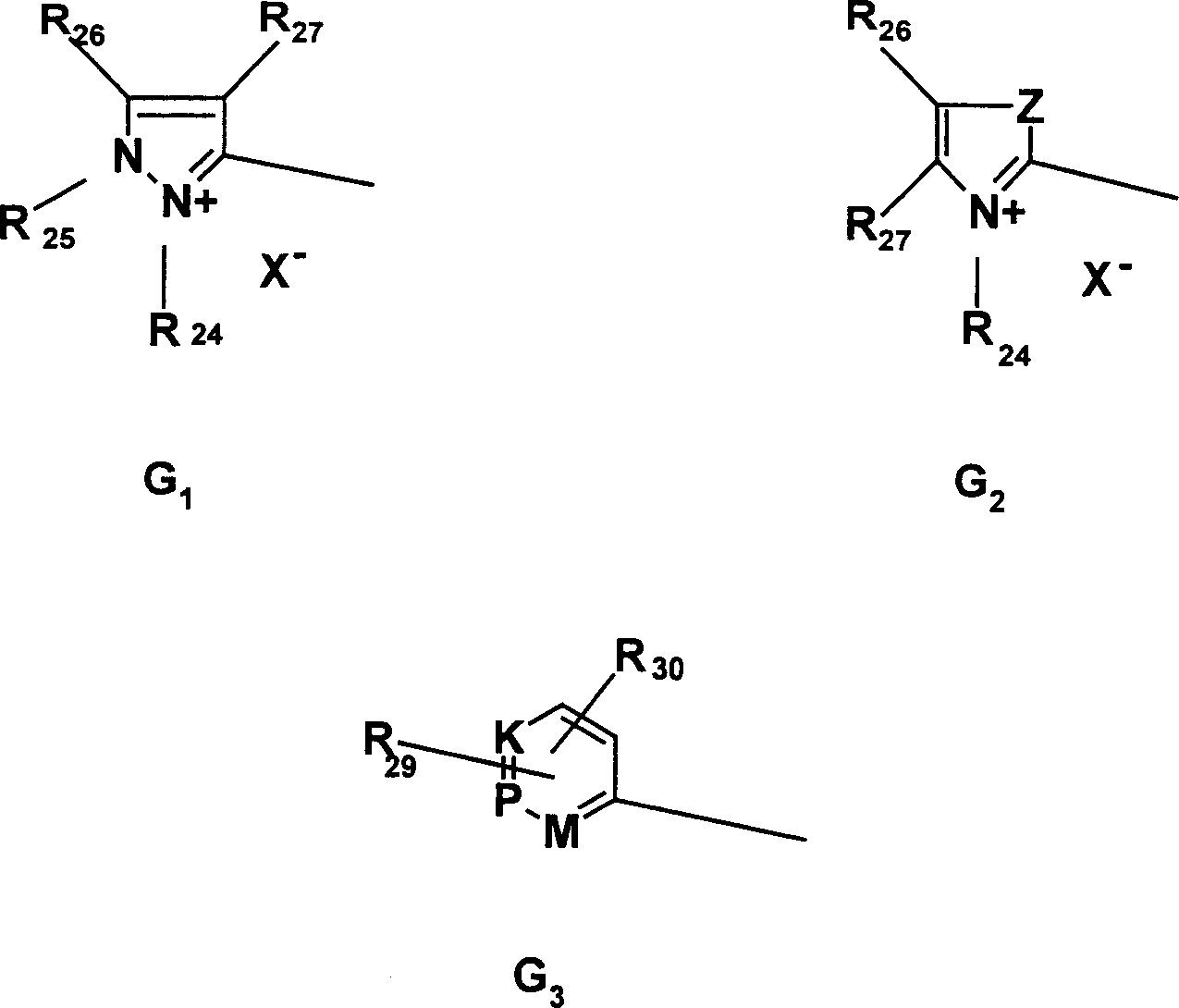

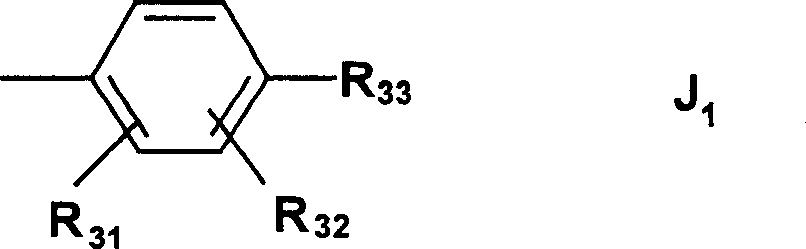

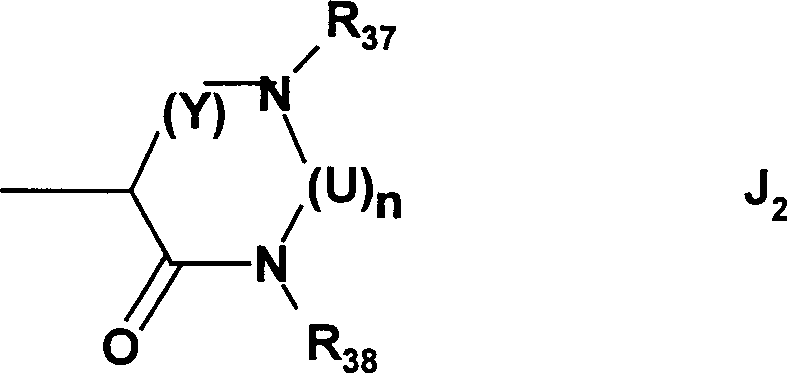

Method used

Image

Examples

Embodiment 1

[0445] Amount (g% of starting material)

Embodiment 2

[0447] The table below contains:

[0448] - composition B according to the invention,

[0449] - Composition Ba identical to composition B, but without direct dyes,

[0450] - a pulverulent composition of the prior art, composition G,

[0451] Amount (g% of starting material)

[0452] Compositions B, Ba, G and Ga were mixed in a ratio of 1+1.5 with a 12% aqueous hydrogen peroxide composition, and the ready-to-use composition thus formed was applied to three strands of chestnut-brown hair at a liquor ratio of 10 , Keep at a temperature of 40°C±2°C for 30 minutes, after treatment, rinse the three strands of hair with water and shampoo, and then dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com