Method for constructing Y shape pillar and suspended declined beam

A construction method and oblique beam technology, which are applied in the fields of formwork/formwork/work frame, on-site preparation of building components, and construction, can solve the problems of difficult construction, low safety factor, and high cost of stadiums, and achieve the solution Small subsidence and displacement, saving engineering costs, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

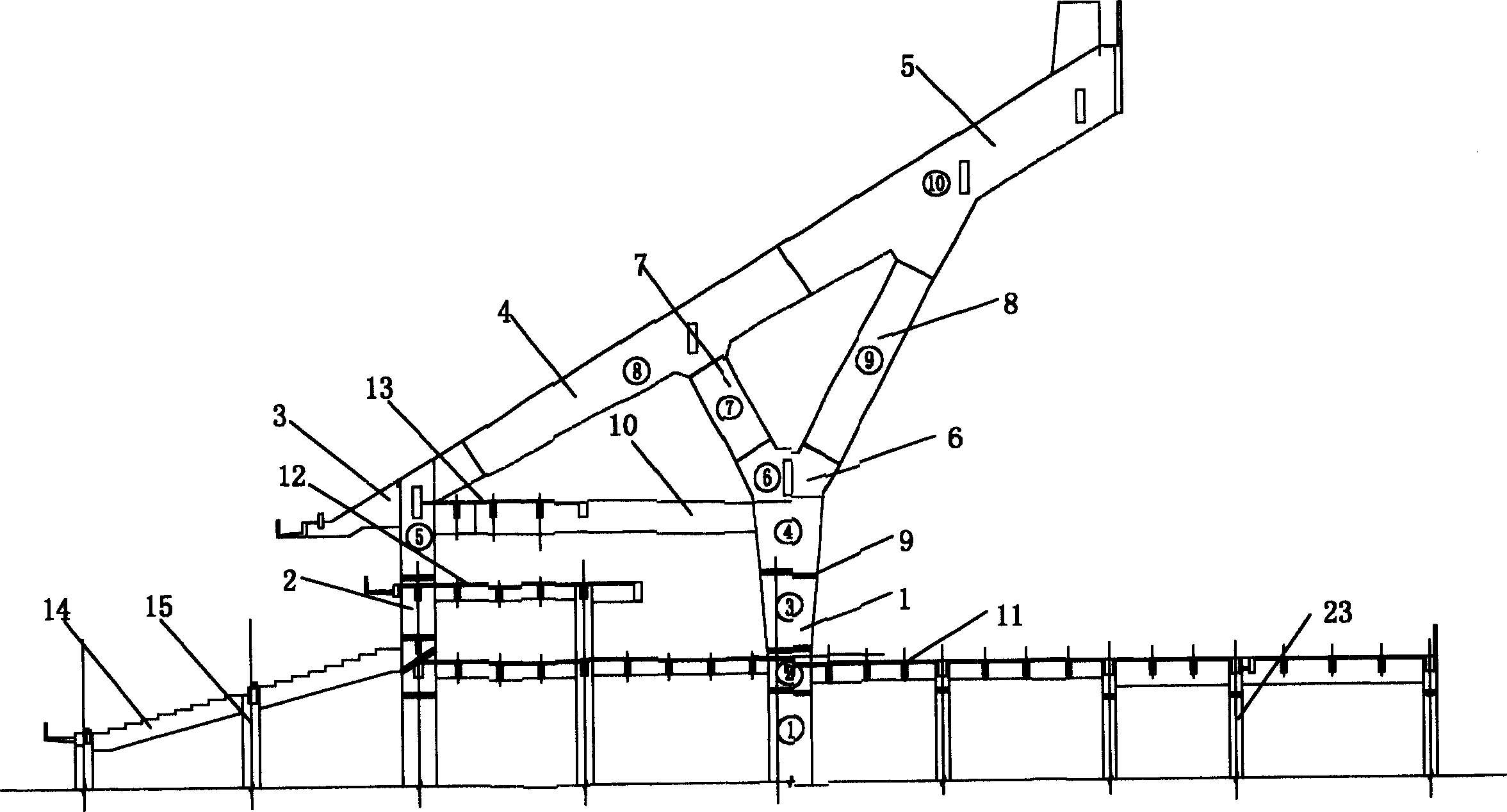

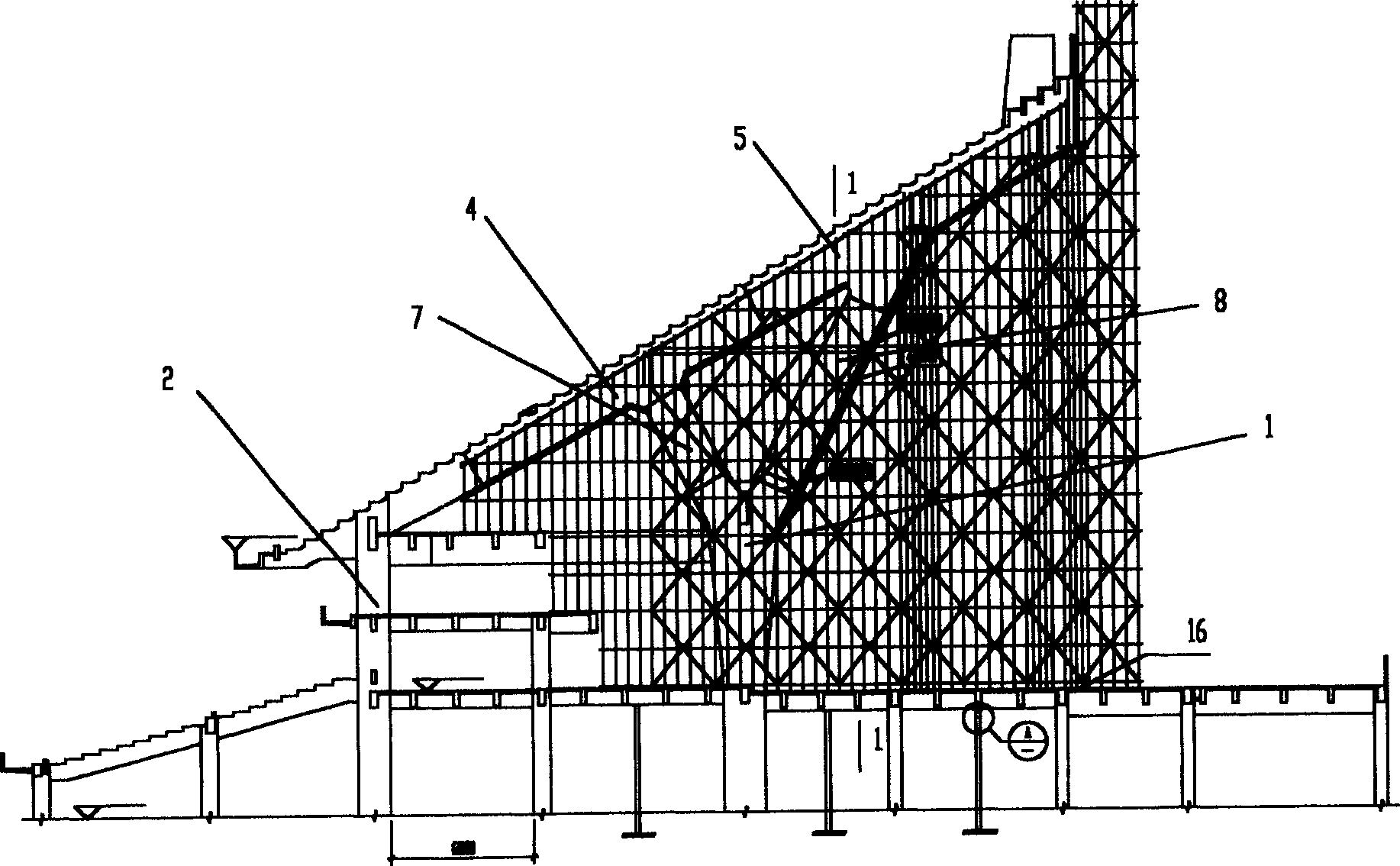

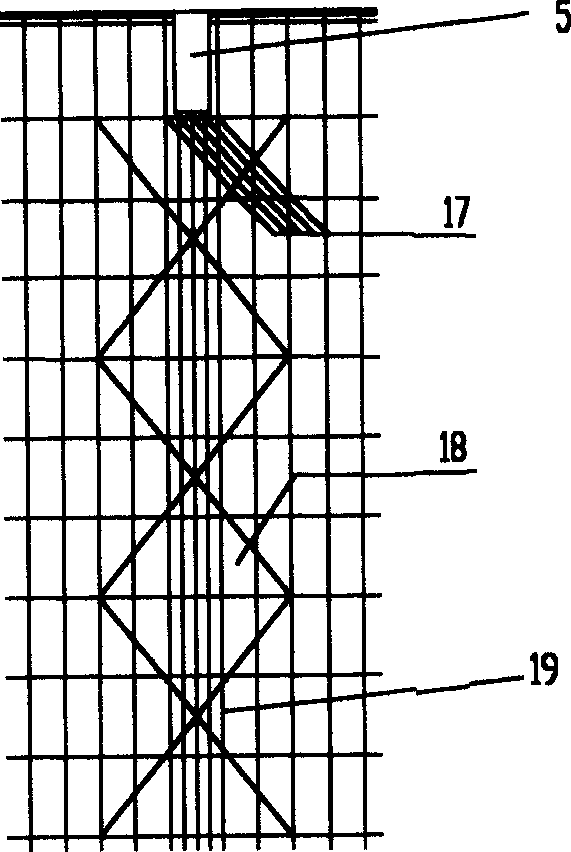

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. A stadium project is the third largest project in the country, and its project uses Y-shaped columns and stepped large inclined beams as the main structural support system. As shown in attached drawings 1-4, the vertical section of the Y-shaped column is 13.7m high, the elevations at the oblique forks are 20.5m and 27.9m respectively, and the maximum cross-section of the column is 1000×5618mm. 56 concrete columns support all stands through stepped inclined beams And the upper structure, the oblique beam is 40m long in the axial direction, is a variable cross-section beam, and its maximum cross-section is 1200×2840mm, the lowest point of the oblique beam is 12.70m, the highest point is 37.03m, the inclination angle is 33.13 degrees, the cantilever length It is 8.68m.

[0025] The first difficulty in the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com