Carbon nano tube/carbon niride nano tube with nano junction and preparation and use

A technology of carbon nanotubes and nanotubes, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effects of low cost, good nonlinear rectification effect, and special electrical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

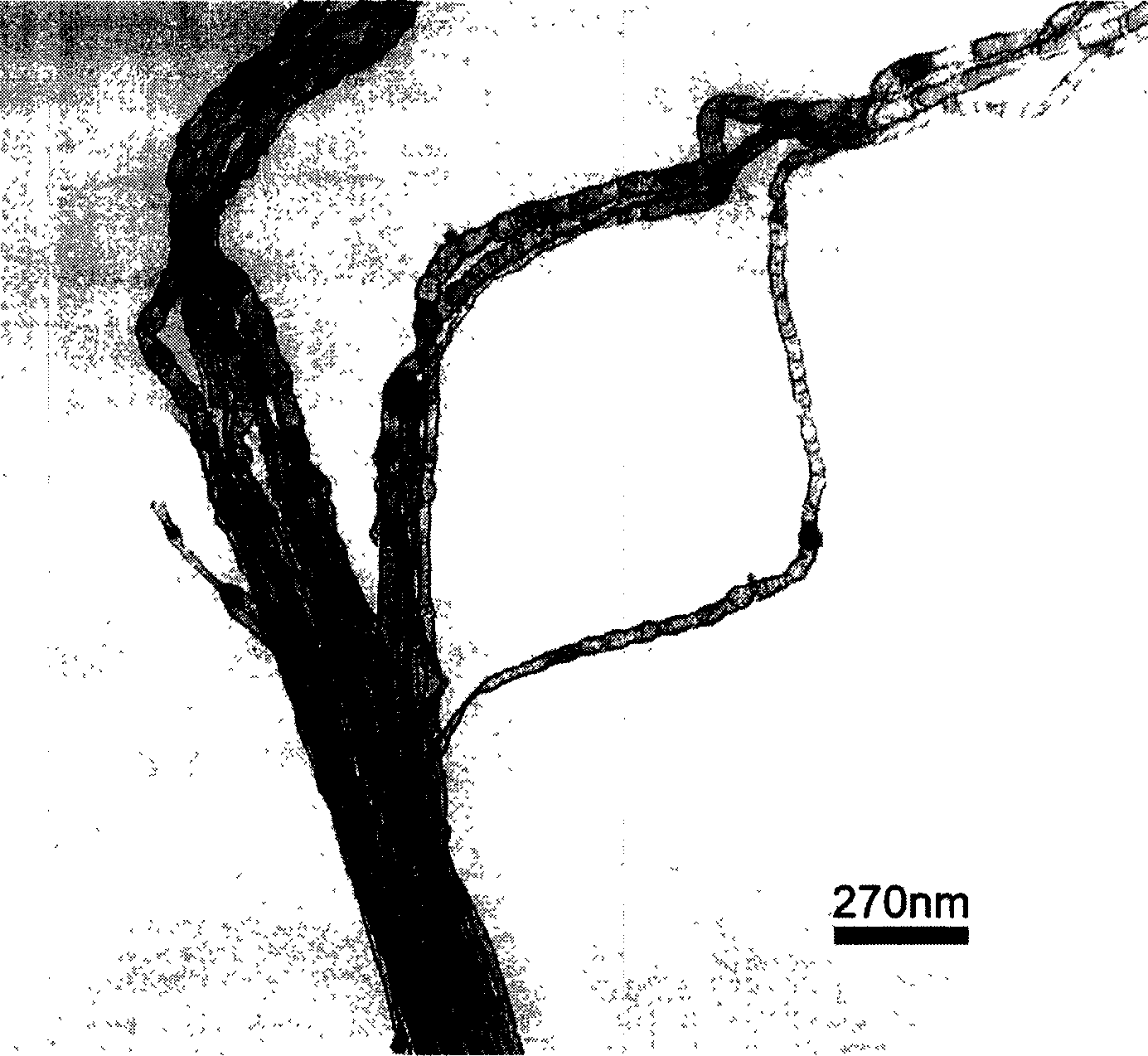

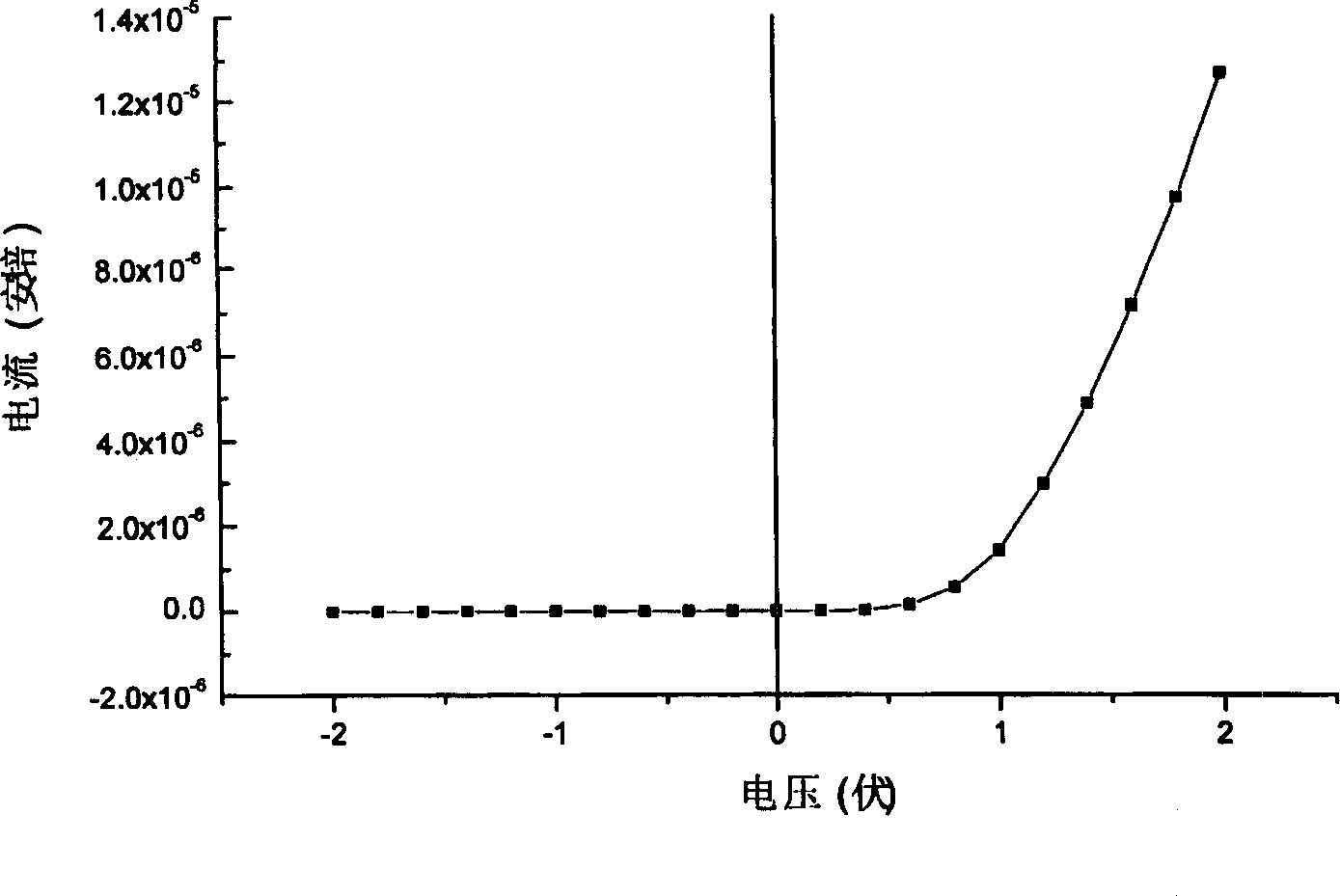

[0025] Example 1: Connect the gas distribution system and feed hydrogen. When the furnace body center temperature reaches 800-1200°C, put the quartz boat containing 0.02 grams of iron phthalocyanine into the area where the furnace mouth temperature is 500-600°C. Under the hydrogen atmosphere, after constant temperature for 1 minute, change the reaction atmosphere, pass into another gas ammonia, after constant temperature for 2 minutes, stop heating, continue to pass hydrogen refrigeration, the flow rate of each gas is 40 milliliters per minute, the obtained product is C / CN with nanojunction X nanotube. figure 1 For the resulting C / CN X TEM images of nanotubes, figure 2 For measuring C / CN X Nanotube current-voltage curves.

Embodiment 2

[0026] Example 2: According to the preparation method of Example 1, just pass ammonia gas first, that is, dope nitrogen element first, and then pass into hydrogen gas, 40% of the resulting product is C / CN with nano junctions X nanotube.

Embodiment 3

[0027] Embodiment 3: according to the preparation method of embodiment 1, just change the amount of phthalocyanine iron into 0.05 grams, 35% are the C / CN with nano-junction in the obtained product X nanotube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com