Preparation method of 2,4-dinitochloro benzene

A technology of dinitrochlorobenzene and p-nitrochlorobenzene is applied in 2 fields, can solve the problems of long reaction time, poor and poor product quality, and the content can only reach 95%, and achieves simplified production process and reduced reaction time. The effect of shortening and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

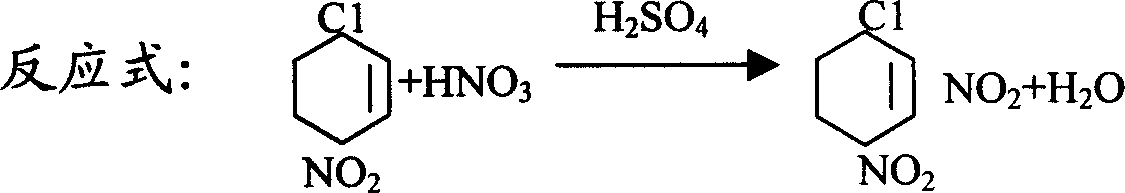

[0007] In the production process of this embodiment, 2,4-dinitrochlorobenzene is obtained through nitration of p-nitrochlorobenzene.

[0008]

[0009] This process operation process, batching ratio: p-nitrochlorobenzene: 98% sulfuric acid: 98% nitric acid=1: 0.9: 0.45, earlier nitric acid and sulfuric acid are mixed in mixed acid pot to make mixed acid, and make it cool. Then add p-nitrochlorobenzene into the reaction pot, cool it to 55-60°C, gradually add the mixed acid, the temperature is controlled at 65-70°C, and drop it in about 4-5 hours, then put the jacket cooling water When the reaction temperature no longer rises, turn on the steam heating, about 1 hour, raise the temperature to 105 ° C, keep warm for 2 hours, take samples to measure the freezing point of the warm product ≥ 47 ° C, when the content is greater than 99%, the nitration reaction is complete, turn off Remove the steam, enter the cooling water, stop stirring, let stand for 1 hour, release the waste nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com