Solar cell assembly and its mounting method

A technology of solar cell components and installation methods, which is applied to electrical components, circuits, photovoltaic power generation, etc., can solve unrecognized problems, achieve the effects of improving processing, increasing work efficiency, and enhancing processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

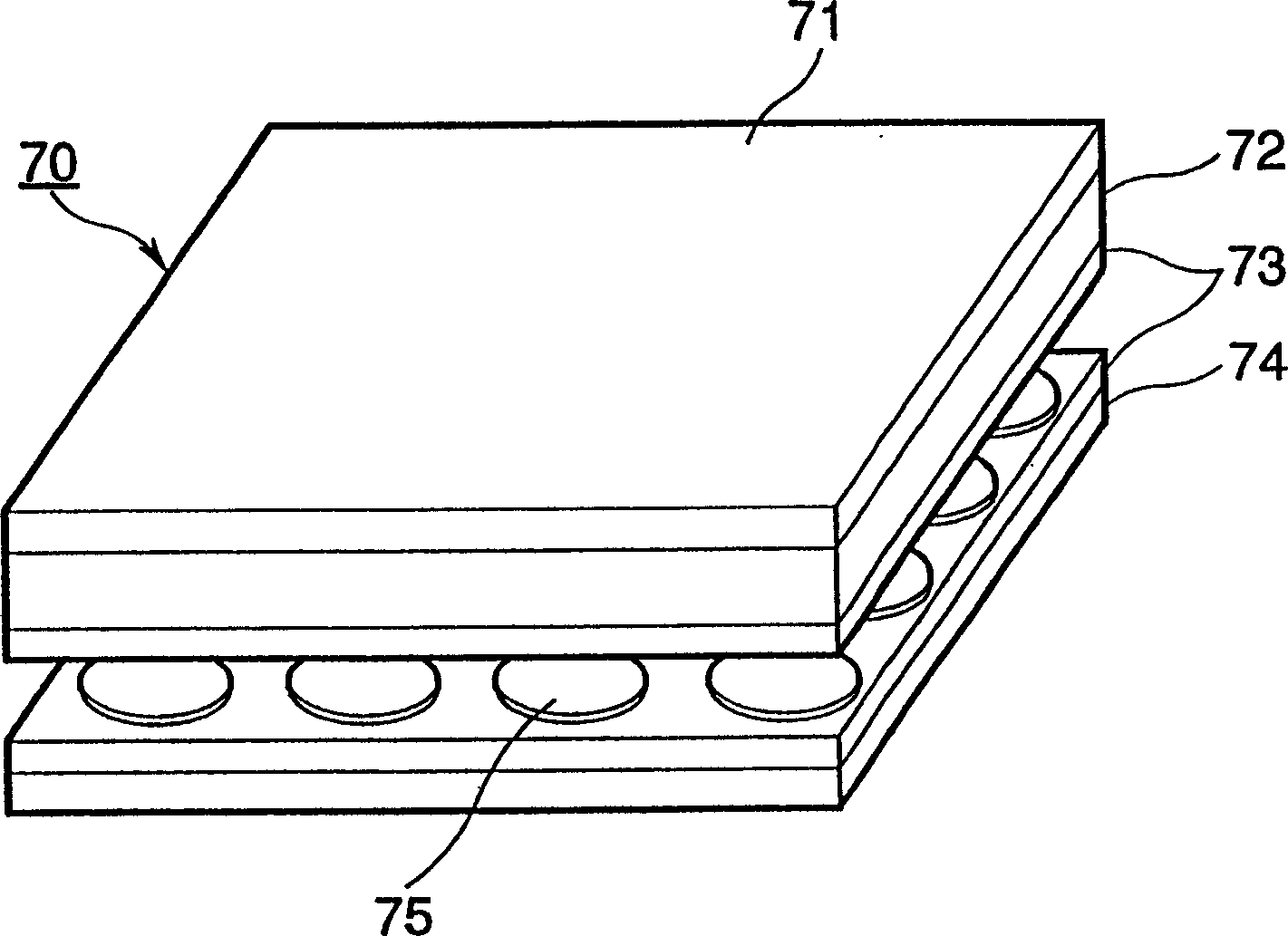

[0104] The present example is characterized in that a solar cell module using an amorphous silicon solar cell device made on a stainless steel substrate is formed into an integrated top assembly, and 96 solar cell modules thus obtained are mounted on a triangular top .

[0105] First, the process of preparing an amorphous silicon solar cell device (not shown in the figure) will be described.

[0106] On a clean stainless steel substrate, an Al layer (5000 Å in thickness) and a ZnO layer (5000 Å in thickness) as a black reflective layer were sequentially formed by sputtering. Subsequently, using the plasma CVD method, the SiH 4 、PH 3 and H 2 The n-type amorphous Si layer is formed in the mixed gas, and the SiH 4 and H 2 The i-type amorphous Si layer is formed in the mixed gas, and the SiH 4 , BF 3 and H 2 A p-type microcrystalline amorphous Si layer is formed in a mixed gas, thereby forming a tandem amorphous Si solar cell device, and the layer structure is n-type layer...

example 2

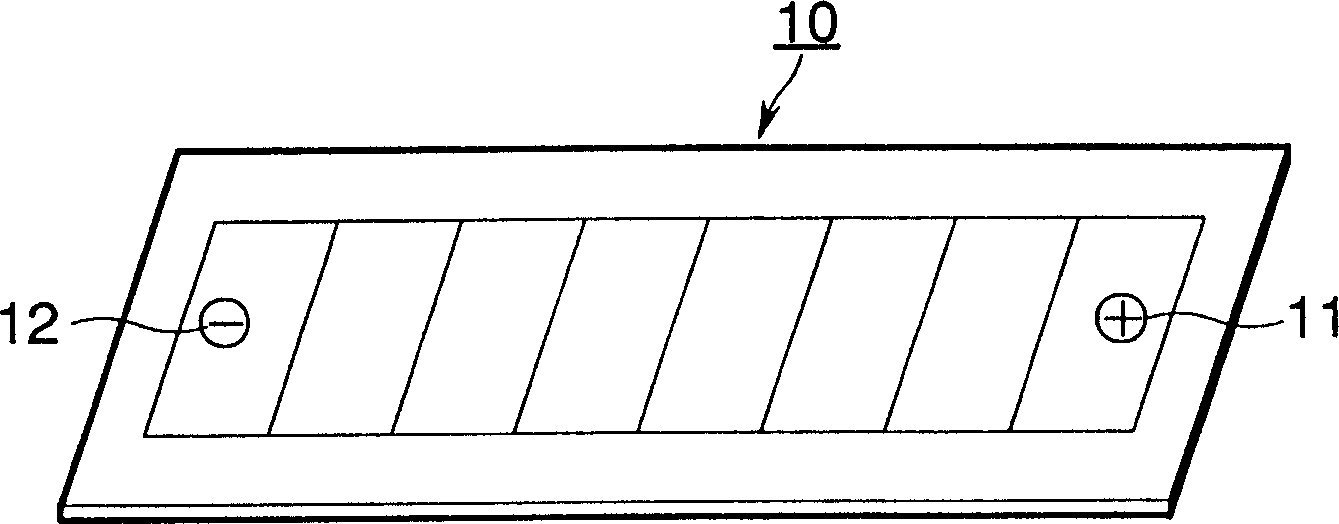

[0138] This example is an example of array installation, in which 15 series-connected monocrystalline silicon solar cell modules are placed in each row, and a total of four rows are connected in parallel. In this example, the sixty solar cell modules installed were all of the same type.

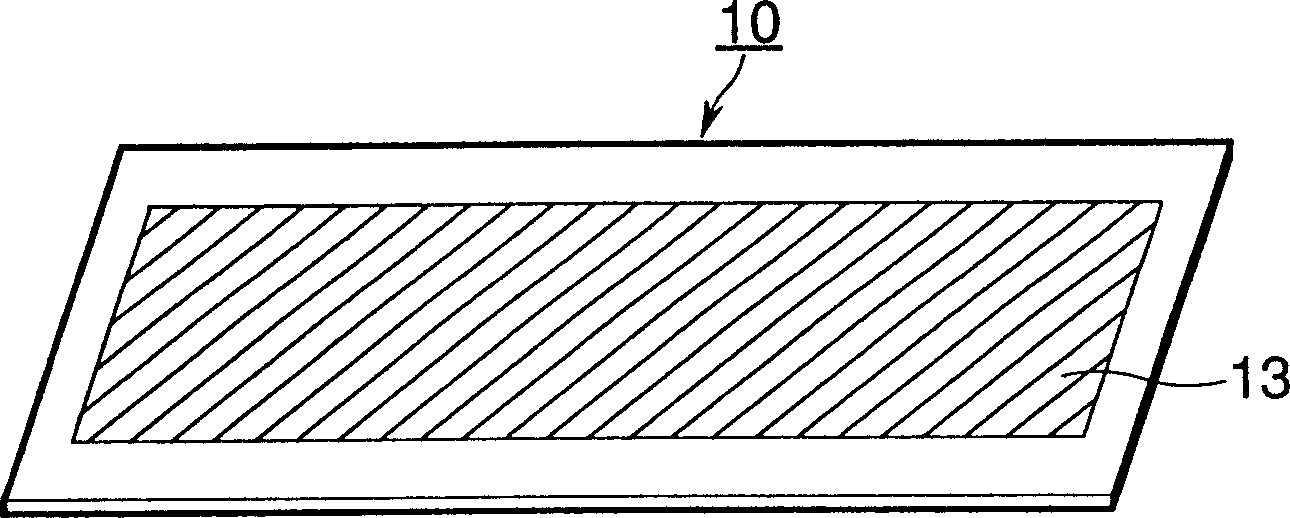

[0139] Before installation, stick a blue adhesive film on each light-receiving surface side of thirty solar cell modules, which is half of all modules, and stick a red adhesive film on each light-receiving surface of the exact other half on the side.

[0140] In this example, the modules with the blue adhesive films thereon were installed in the first and third rows, and the solar cell modules with the red adhesive films thereon were installed in the second and fourth rows. At the time of mounting, since adhesive films of different colors are applied to the surface of the module between adjacent rows, row identification is easy and installation workability is excellent. After installation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com