Method for fabricating housed typed stretching car shed and the housed typed stretching car shed

A manufacturing method and technology of telescopic sheds, which are applied in the field of retractable telescopic carports, can solve the problems affecting the service life of the vehicle, the owner's mood and use, and achieve the effect of beautiful appearance, simple process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

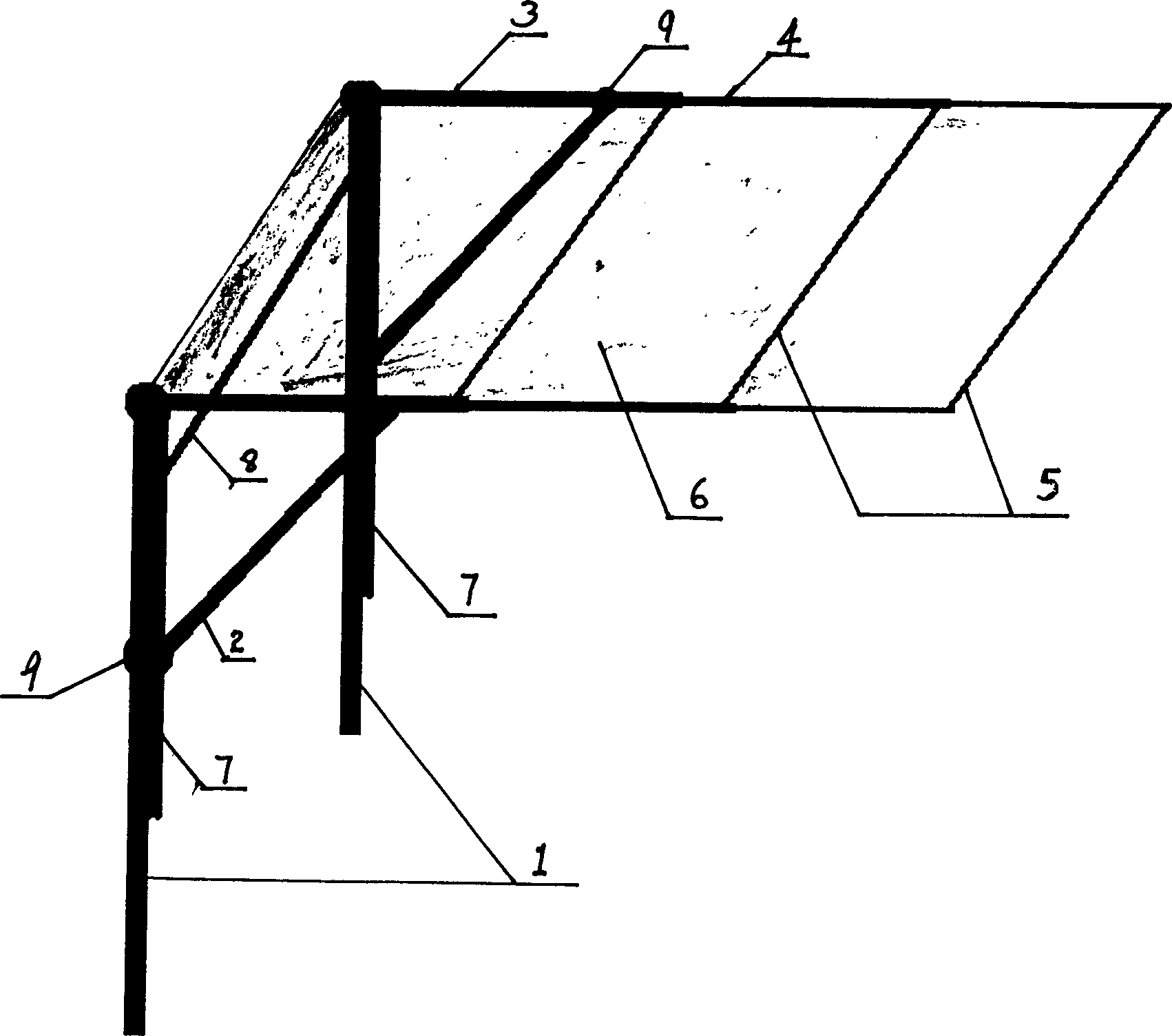

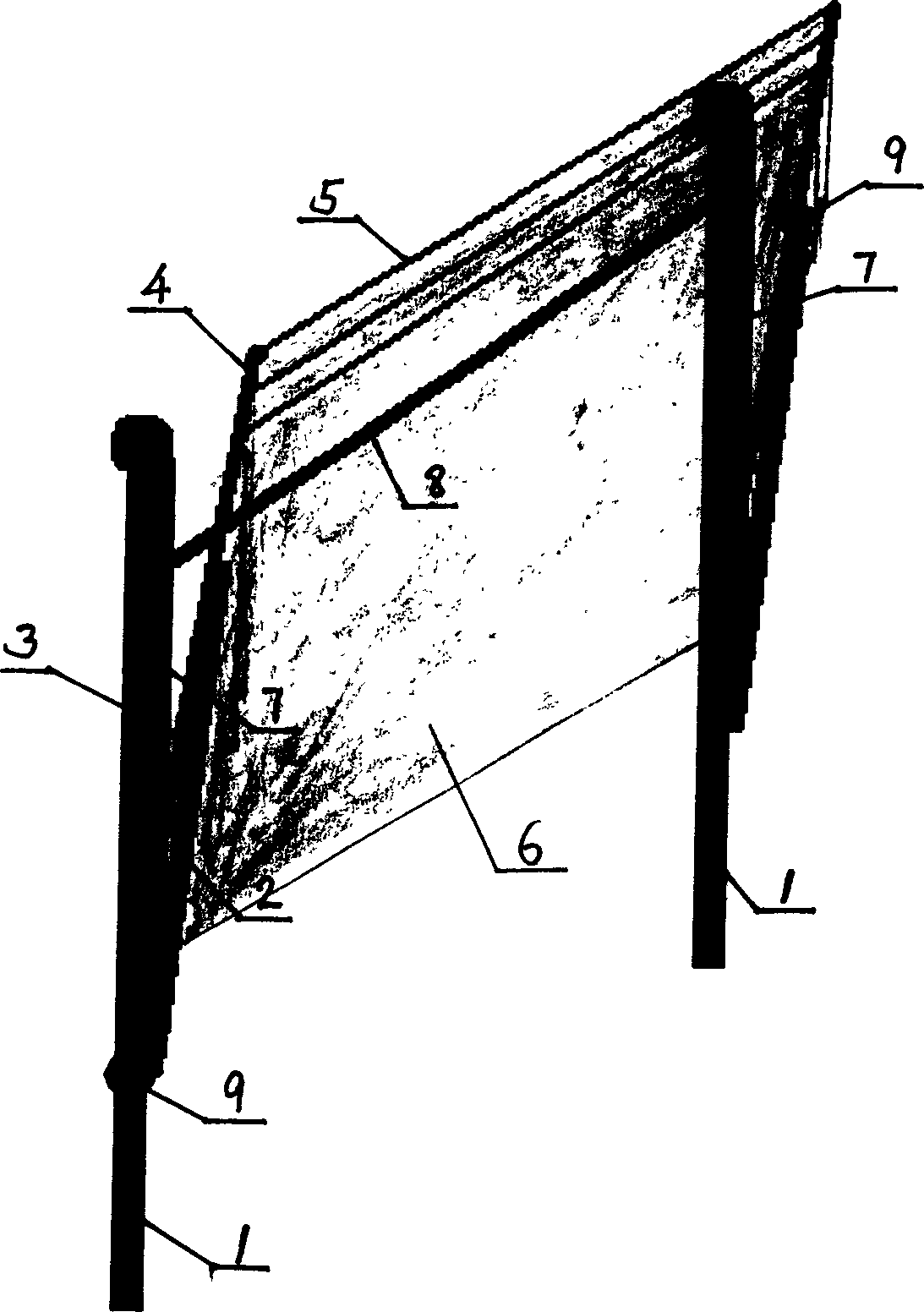

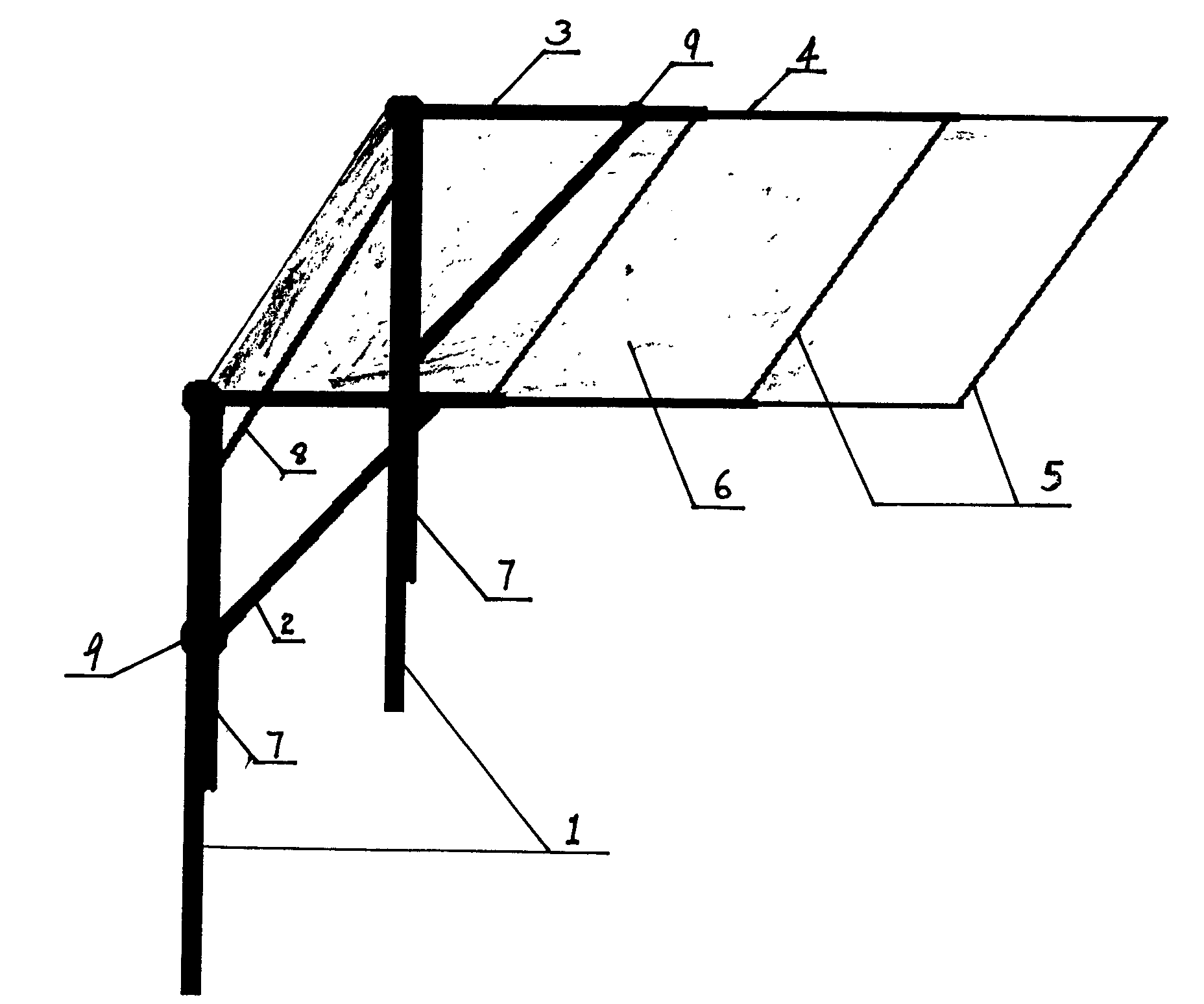

[0018] like figure 1 , 2 As shown, this retractable carport is set on a diamond-shaped parking space with a tree wall and a road on one side. It adopts an electric type: the height of the car is 1.42 meters, the length is 4.428 meters, and the width is 1.66 meters. Two, close to the tree, the connection line is parallel to the tree wall, one end is fixed vertically on the base on the ground, and the ground is fixed on the ground with cement, 176 cm above the ground, with a distance of 2.00 meters, and 60 cm from the top. Lead screw; the storage rod 2 is 0.5 meters long, one end is connected to the column 1, and can be rotated up and down at the connection point, and the other end is connected to the base section 3, and the connection point can slide; the base section 3 is 1.3 meters, and its tail end is on the column The screw on 1 moves up and down, and is controlled by a motor to move up and down, and finally fixed on the top of column 1, and is parallel to the ground or sl...

specific Embodiment approach 3

[0020] like figure 1 , 2 As shown, the retractable carport is set on a rectangular parking space where one side is a tree wall and the other side is a road. The pull-up manual type is adopted: the height of the car is 1.42 meters, the length is 4.428 meters, the width is 1.66 meters, and the length is 1.8 meters. There are two columns 1, close to the edge of the tree, the connection line of which is parallel to the tree wall, and one end is vertically fixed on the ground, 20 cm underground, 160 cm above the ground, with a distance of 5.00 meters; the base section 3 is 1.05 meters, and its tail end can be rotated. Fixed on the top of the column 1; the storage rod 2 is 0.6 meters long, one end is fixedly connected to the base section 3, and can be rotated up and down at the connection point, and the other end is inserted into the reserved groove on the column 1; In the base section 3, the length of the telescopic section 4 is 1.25 meters, the cross-sectional shape of the shrink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com