Terminal structure of direct electric current superconducting cable and dc superconducting cable line

A technology of superconducting cable and direct current, which is used in cable accessories, cable terminals, superconducting devices and other directions of low temperature cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, a detailed description of the present invention will be given.

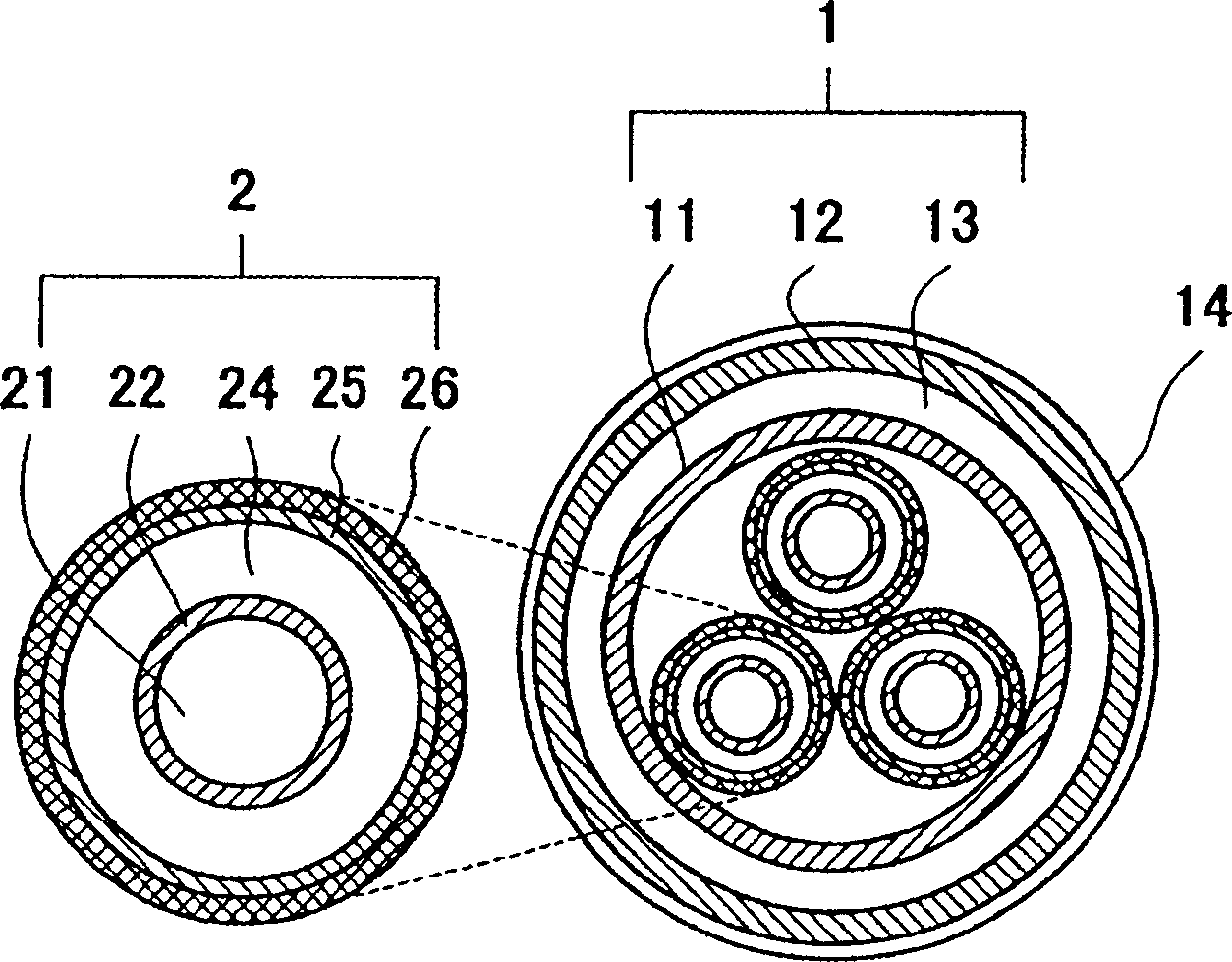

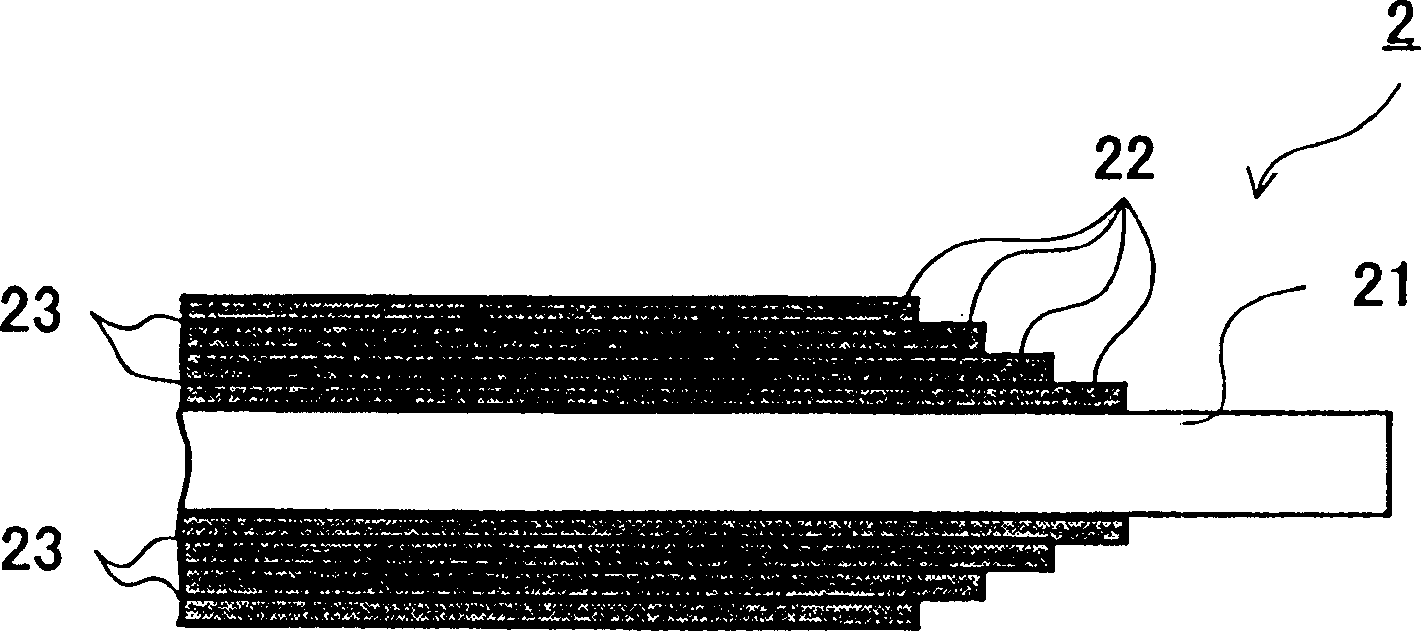

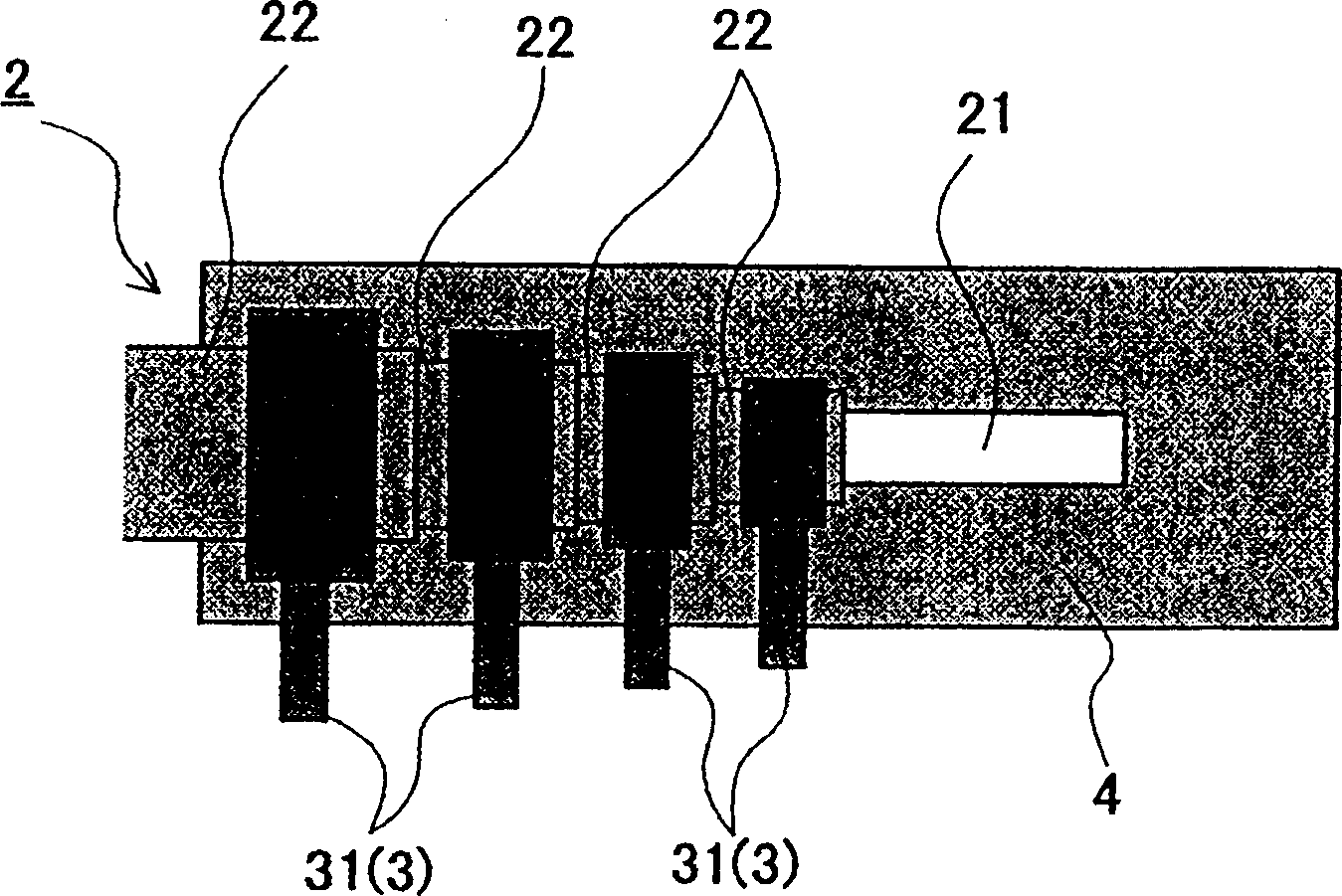

[0018] In the drawings, the same reference numerals are assigned to the same elements, and their explanations will not be repeated. The dimensional ratios in the drawings are not always the same as those described in the specification. figure 1 is a cross-sectional view of a superconducting cable according to the present invention, while figure 2 The termination structure of the conductor portion in the core of the superconducting cable is shown. image 3 and Figure 4 The terminal structure of the conductor elements of the superconducting cable core connected to the output conductor is schematically illustrated. Figure 5 is a schematic diagram showing the structure of a cable line using the superconducting cable, and an explanation about the structure of the cable core is given in the drawing.

[0019] 【Overall structure of superconducting cable】

[0020] Superconducting cables can hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com