Optical head, optical information recording/reproducing device and applied apparatus

An optical information and reproduction device technology, applied in the field of optical heads, can solve the problems of aberration deterioration, beam shaping magnification change, impracticality, etc., and achieve the effect of improving light utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

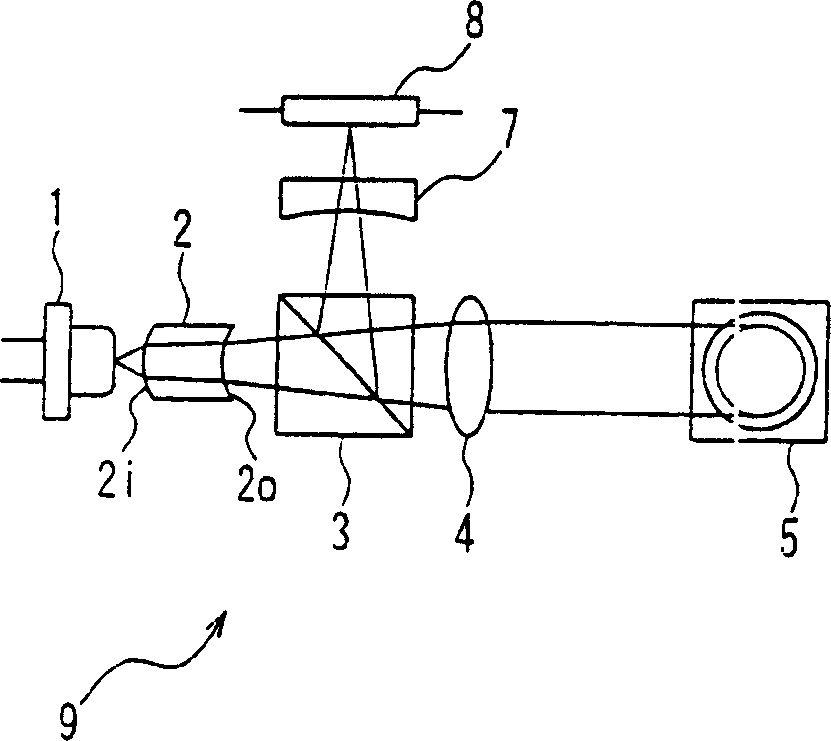

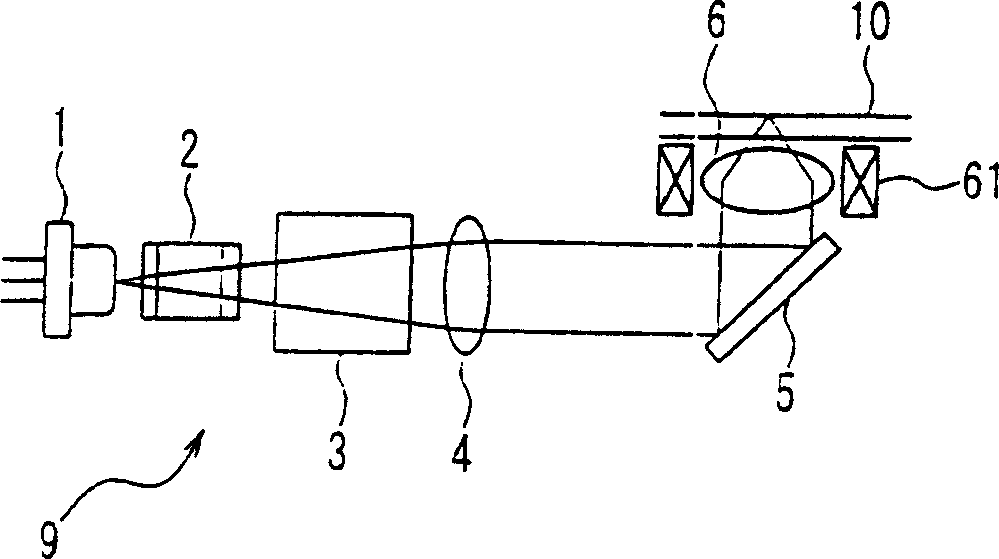

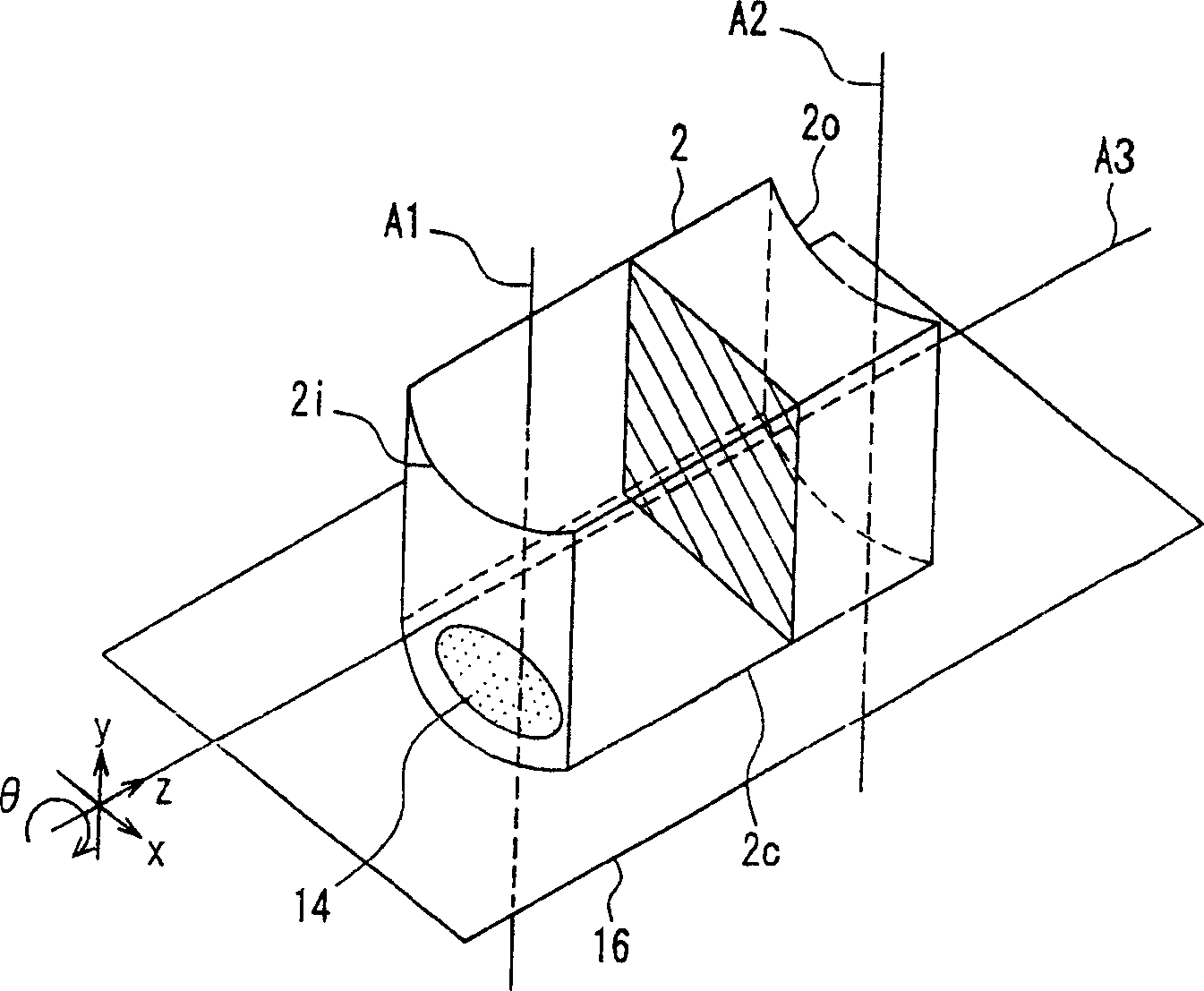

[0065] Figure 1A and 1B An optical head 9 according to Embodiment 1 of the present invention is shown. Figure 1A is the top view of the optical head 9, and Figure 1B is a side view of the optical head 9. The beam emitted from the light source 1 is emitted from one end face of the thin active layer so that the shape of the beam is elliptical, and the ratio between the minor axis and the major axis of the beam is about 1:3. Through the following beam shaping lens 2, the elliptical diverging beam emitted from the light source 1 is shaped into a substantially circular diverging beam, the beam passes through the beam splitting prism 3, and is collimated into a substantially parallel beam through the collimating lens 4, It is reflected by the mirror 5, converged by the objective lens 6, and then irradiated on the optical disc 10. The light beam reflected by the optical disc 10 returns along the opposite path, is reflected by the dichroic prism 3 , passes through the detection...

Embodiment 2

[0087] Figure 4A and 4B An optical head 29 according to Embodiment 2 of the present invention is shown. Different from Embodiment 1, the beam shaping lens 22 is composed of a cylindrical lens 22a and a cylindrical lens 22b. Other structural aspects are the same as those in Embodiment 1, so details will not be repeated for these parts. Figure 5 is a perspective view of the beam shaping lens 22.

[0088] Typically, axial rotational symmetry is used in lens manufacture so that rotational adjustments of the front and back of the lens are not required. However, in a lens without axial rotational symmetry, such as the beam shaping lens 2 of Embodiment 1, it is necessary to pay attention to the rotational error of the two surfaces. When the magnification of the beam shaping is about a factor of 2, the aberration due to the rotation error will become large. Therefore, the tolerable rotation error is limited to less than 0.05 degrees. In Embodiment 2, the beam shaping lens 22 i...

Embodiment 3

[0100] Figure 7A and 7B Embodiment 3 according to the present invention is shown, and shows the light source 1, the beam shaping lens 22 and its peripheral parts. Other aspects are the same as in Embodiment 1, so these parts will not be repeated. The details of the beam shaping lens 22 are the same as those described in Embodiment 1 or Embodiment 1.

[0101] Usually, due to the manufacturing error of the light source 1, the light-emitting point 21 will deviate by about 0.1 mm, and the optical axis will be inclined by about 3°. In order to correct this deviation, positioning adjustment and tilt adjustment of the light source 1 must be performed. Such as Figure 7A As shown, the light source 1 is fixed on the bracket 11 by press fit or caulking. The bracket 11 can be tilted and adjusted relative to the adjustment plate 12 , so as to correct the tilt of the optical axis of the light source 1 . The adjustment plate 12 can be positioned and adjusted relative to the optical b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com