Valve controlled lead acid accumulator positive lead paste

A lead-acid battery, positive lead paste technology, applied in lead-acid battery electrodes, lead-acid batteries, battery electrodes and other directions, can solve the problems of uneven lead paste, short battery cycle life, easy to hurt personnel, etc., to prolong the deep cycle longevity, prolong the service life of equipment, and eliminate the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

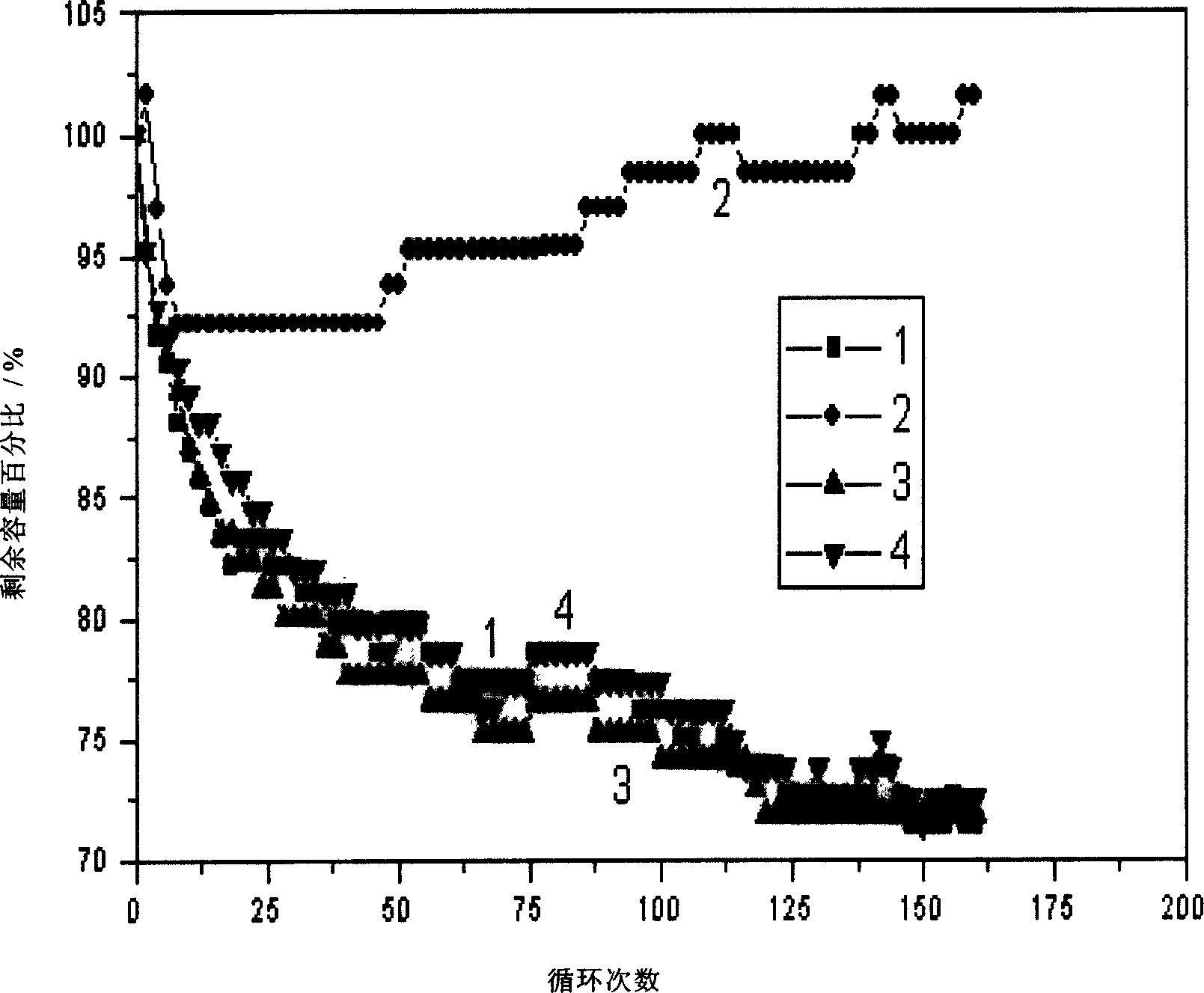

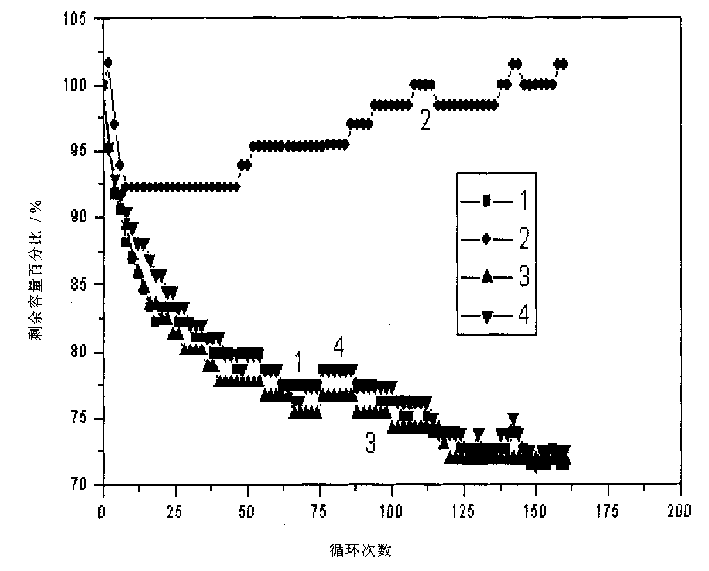

[0029] Examples of the present invention are exemplified in the form of a list below. The lead paste of the present invention is composed of the following weight percentage components based on its weight:

[0030] Example Short fiber% Water% Lead powder%

[0031] 1 0.1 10 margin

[0032] 2 0.1 5 margin

[0033] 3 0.2 5 margin

[0034] 4 0.4 10 margin

[0035] 5 0.1 15 margin

[0036] The short fiber is polyacrylonitrile material.

[0037] The preparation process of lead paste:

[0038] 1. Add short fibers to the water and stir to evenly disperse the short fibers;

[0039] 2. Add lead powder and stir to make it even.

[0040] The role of each component:

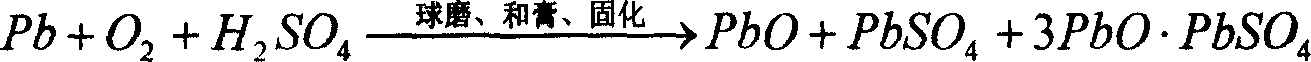

[0041] 1. Lead powder is used as the positive active material to give the battery capacity;

[0042] 2. Short fibers are used as the skeleton for the bonding of active materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com