Preparation method of thymopentapeptide

A technology of thymus and resin, which is applied in the field of preparation of polypeptide drugs, can solve the problems of long process cycle, complex process, troublesome refining of crude products, etc., and achieve the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

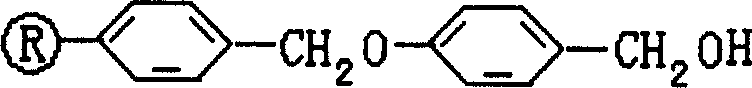

Image

Examples

Embodiment 1

[0039] Use 10Mm Wang resin as raw material.

[0040] Fmoc-Tyr(tBu)-Wang resin preparation:

[0041] Take a dry 250ml eggplant-shaped bottle and add the resin to it, the resin is CH 2 Cl 2 After soaking for half an hour, use CH 2 Cl 2 Wash 3 times and drain;

[0042] Weigh 22.98g of Fmoc-Tyr(tBu)-OH, dissolve it in DMF, add 7.65g HOBT, add 1.22g DMAP after it is fully dissolved, and add it to the resin after dissolution;

[0043] After adding 50ml DIC / DMF (1mM / ml) to the resin, adjust the pH to 6.5 with pyridine, seal and react at 30°C for 24 hours;

[0044] After the reaction, use CH 2 Cl 2 , EtOH, DMF wash the resin, each wash 3 times;

[0046] Dipeptide: Fmoc-Val-Tyr(tBu)-Wang resin;

[0047] Weigh 10mMFmoc-Tyr(tBu)-P into a 250ml eggplant-shaped bottle, soak, and 2 Cl 2 Wash 3 times and drain;

[0048] Deprotection: Add 25% hexahydropyridine / DMF80ml to the resin, 20 minutes at 30°C.

[0049] Washing: CH 2 Cl 2 DMF CH 2 Cl 2 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com