Gray mask defect checking method

A technology of gray-tone mask and defect inspection, which is applied in the field of defect inspection of gray-tone masks, and can solve problems such as indistinct gray-tone graphics, decreased light transmittance of subtle light-transmitting parts, and easy damage to glass substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

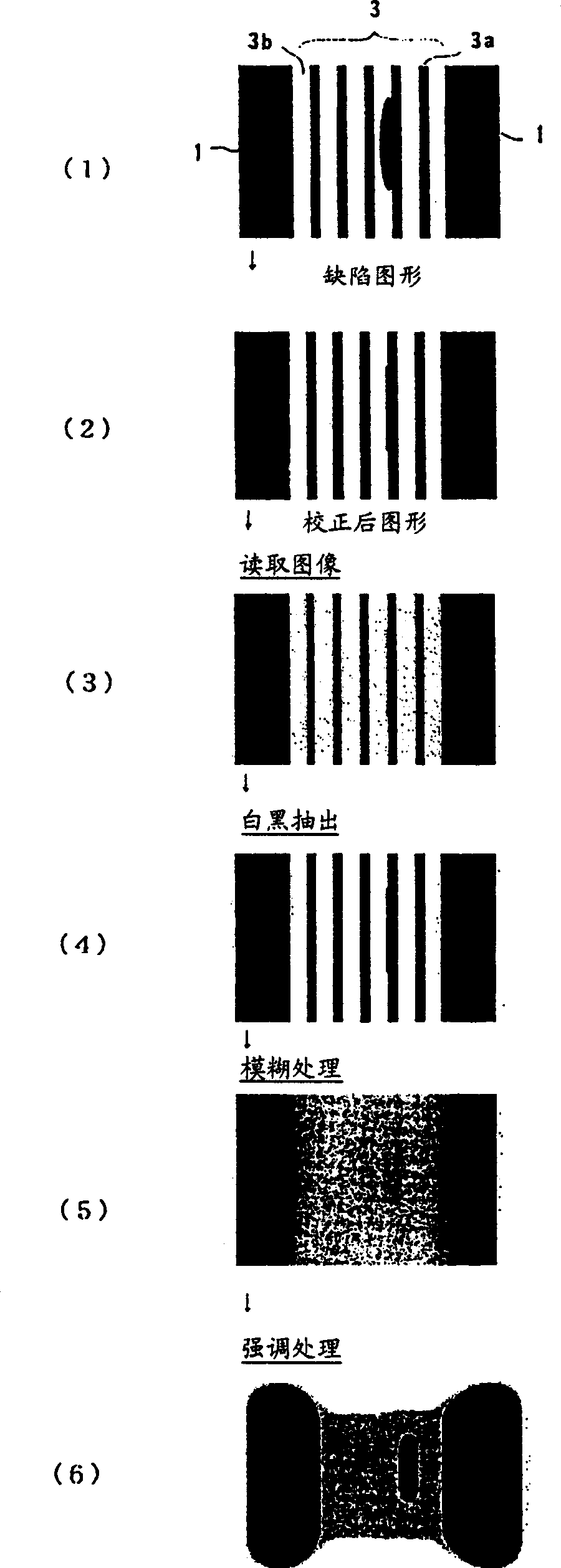

[0083] figure 1 It is a partial top view for explaining the method of correcting and inspecting a black defect in a gray tone part according to an embodiment of the present invention.

[0084] Such as figure 1 As shown in (1), use figure 2 The laser repair device shown, etc., removes black defects and performs corrections similar to normal patterns (outside the CD allowable accuracy of normal patterns) ( figure 1 (2)). At this time, the use of a laser repair device to remove the thick line width (addition of so-called correction accuracy) will affect the adjacent fine light-transmitting portion 3b (glass portion pattern) and light-shielding pattern 3a, so it is not performed. In addition, in this embodiment, since the black defect is removed by using a laser repairing device, the fine light-transmitting portion 3b (glass portion pattern) is damaged, and the light transmittance of the corrected portion is lowered.

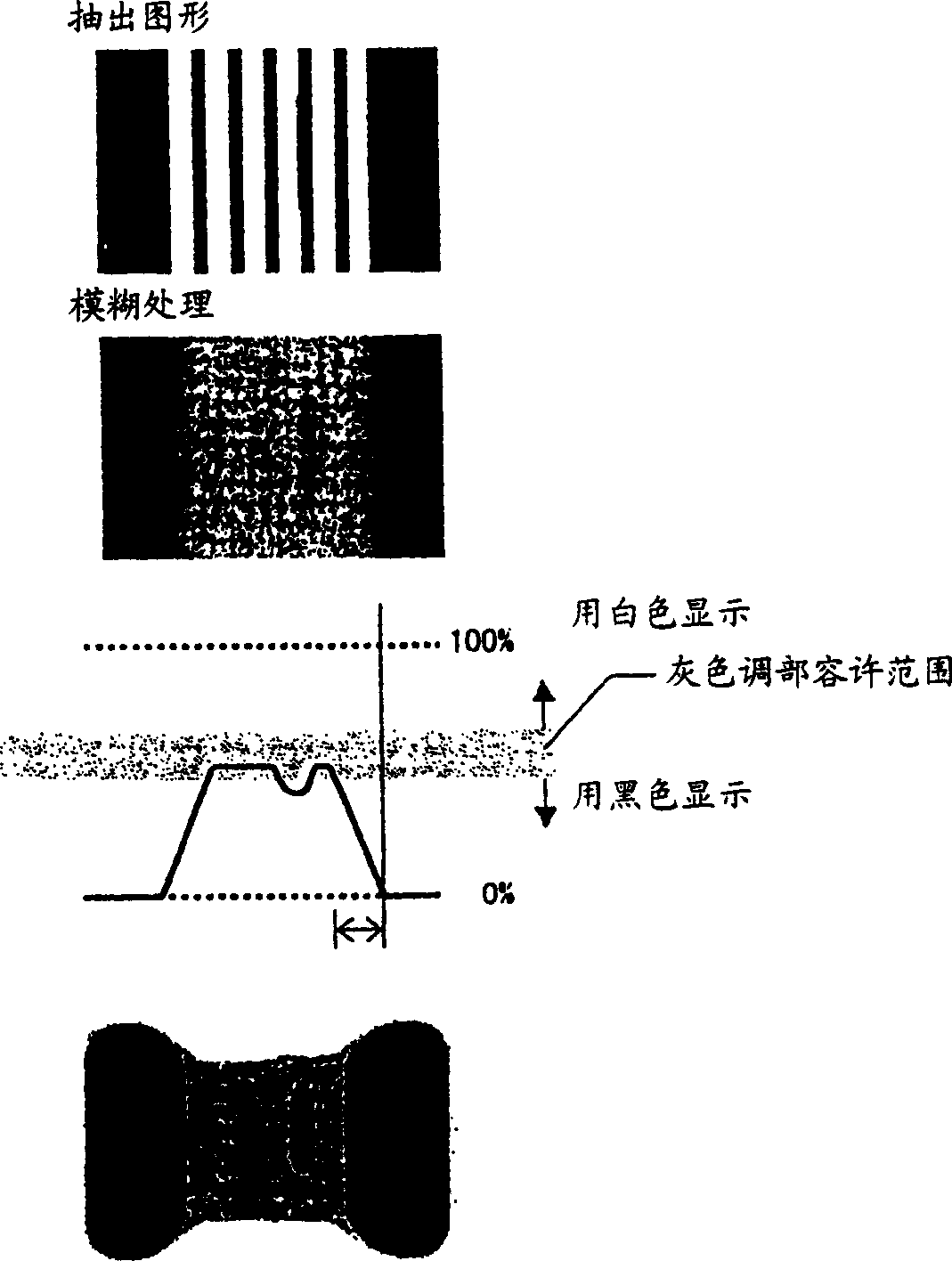

[0085] The image processing of the present invention i...

Embodiment 2

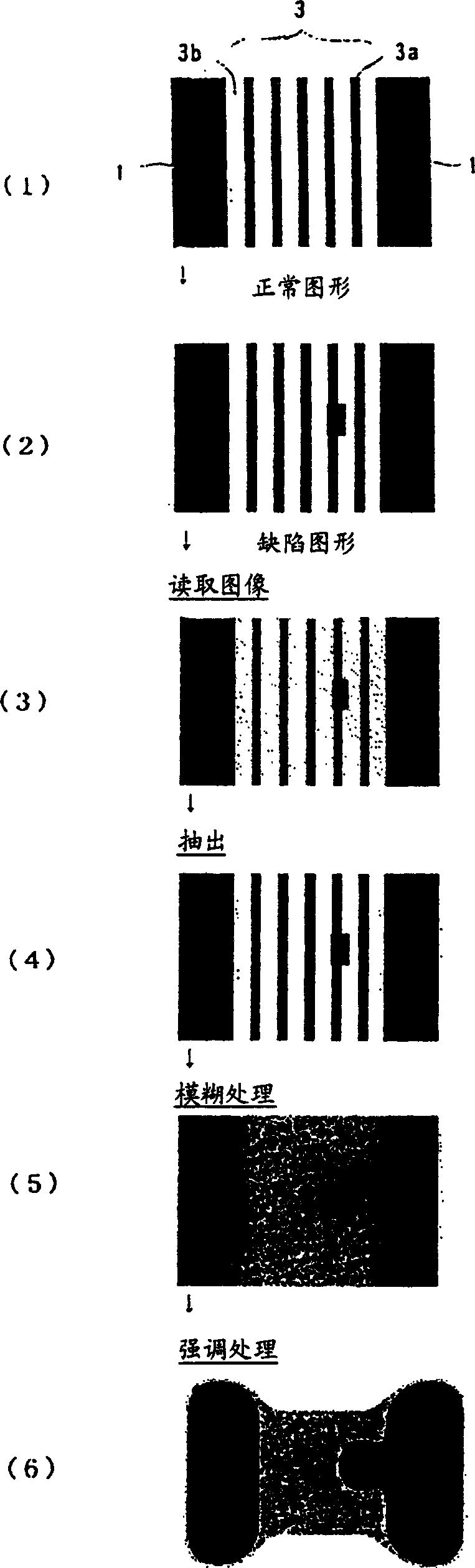

[0094] image 3 It is a partial top view for explaining the method of correcting and inspecting a black defect in a gray tone part according to an embodiment of the present invention.

[0095] This example involves the following situations: for image 3 The normal figure of the gray tone part 3 shown in (1), in image 3 Minute black defects (convex defects) that are not problematic in terms of specifications (pattern line width and shape) set to meet user requirements shown in (2) occur in a part of the light-shielding pattern 3 a of the gray tone portion 3 . At this time, further removal of fine black defects (convex defects) using a laser repair device (so-called addition of correction accuracy) will affect the adjacent fine light-transmitting portion 3b (glass portion pattern) and light-shielding pattern 3a, so it is not performed. .

[0096] The image processing of the present invention is performed on an image including a region of the corrected figure. That is, an im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com