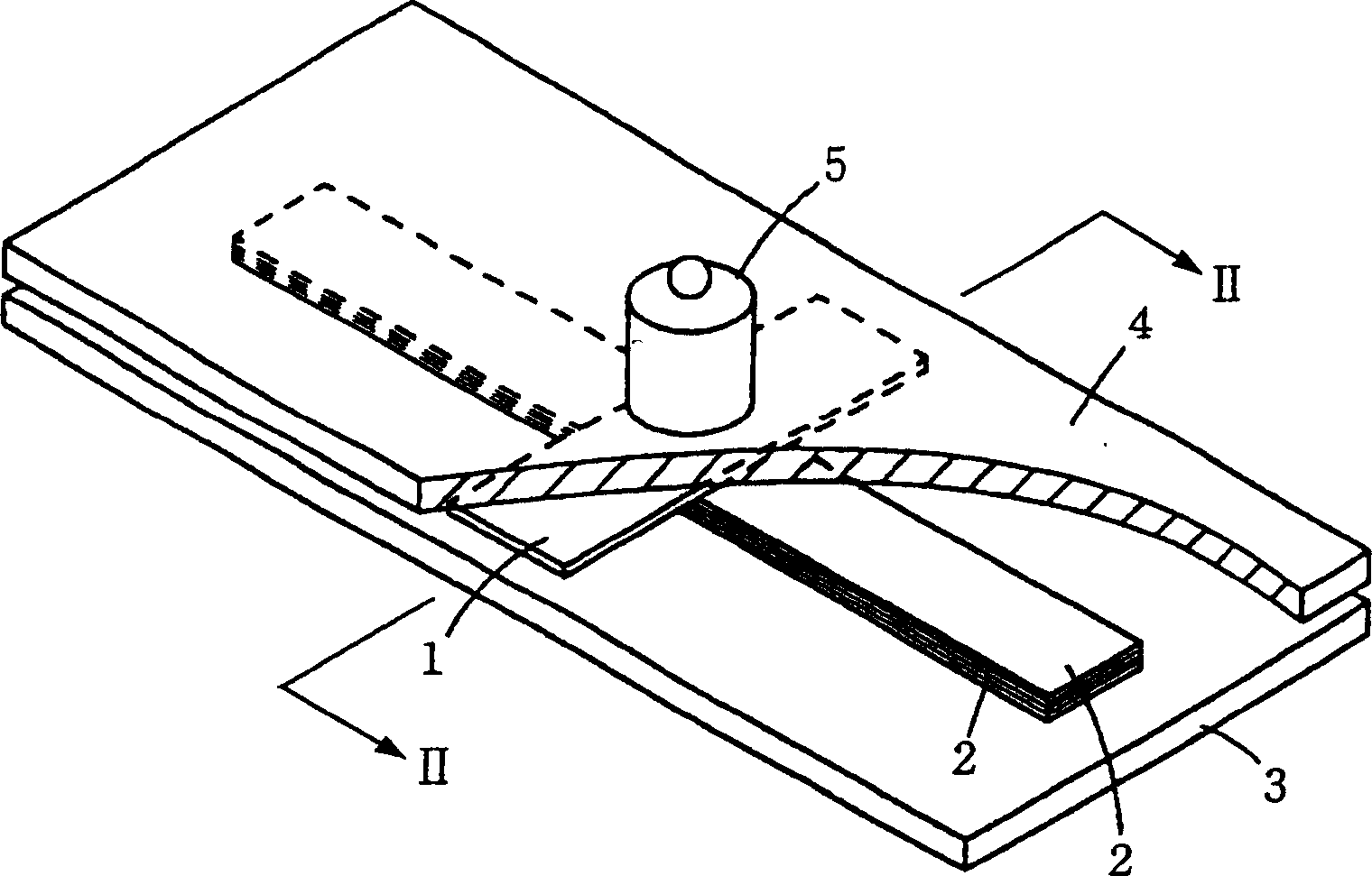

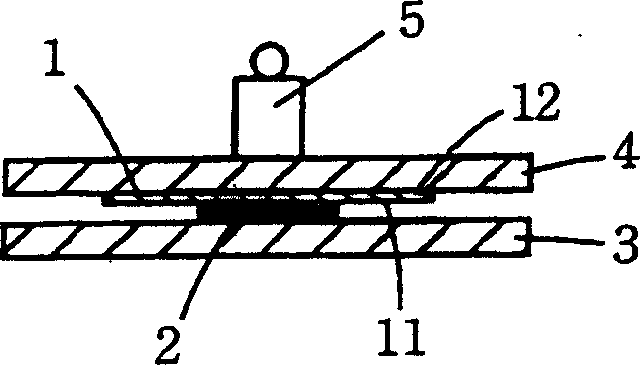

Water-disintegrable resin film laminated water-disintegrable resin film, water-disintegrable composite laminate and method for production thereof

A hydrolyzable resin, lamination film technology, applied in synthetic resin layered products, chemical instruments and methods, coatings, etc., can solve the problems of mechanical strength decline, failure to take into account, underwear fouling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

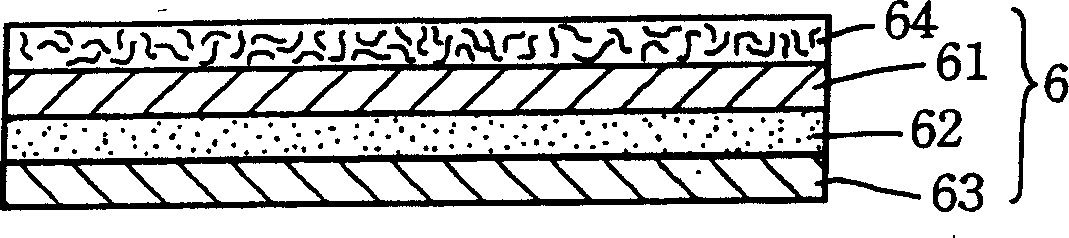

[0112] A given amount of alkylene oxide-modified polyvinyl alcohol (polyoxyethylene group content: about 23% by weight, degree of saponification: 99% by mole, degree of polymerization: 500), ethylene-vinyl alcohol copolymer (1 ) (ethylene content: 6 mol%, saponification degree: 99 mol%, polymerization degree: 500) and ethylene-vinyl alcohol copolymer (2) (ethylene content: 6 mol%, saponification degree: 99 mol%, polymerization degree: 1000 ) composed of polyvinyl alcohol resin and glycerin as a plasticizer were provided to the extruder, and extruded from the T die after being melted and mixed to obtain a hydrolyzable resin film with a thickness of 20 μm.

[0113] Then, a toluene-methanol mixed solution of ethyl cellulose (trade name "N-100" manufactured by Ha-Kyures Co., Ltd.) was coated on the entire surface of the above-mentioned hydrolyzable resin film by the gravure coating method, and the integrated thickness was laminated. A hydrolyzable resin laminated film was obtained...

Embodiment 4

[0115] A hydrolyzable resin laminated film was obtained in the same manner as in Example 3 except that the thickness of the hydrolyzable resin film was changed to 30 μm.

Embodiment 5

[0117] In addition to coating one side of the hydrolyzable resin film with an ester-type thermoplastic polyurethane resin (trade name "Pandex T-5205" manufactured by Dainippon Ink Chemical Co., Ltd.) instead of ethyl cellulose, a waterproof film with a thickness of 5 μm is laminated and integrated. Except for the layer, a hydrolyzable resin laminated film was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com