Lameller component of fusion reactor

A reactor and component technology, applied in fusion reactors, thermonuclear fusion reactors, reactors, etc., can solve problems such as complex and expensive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

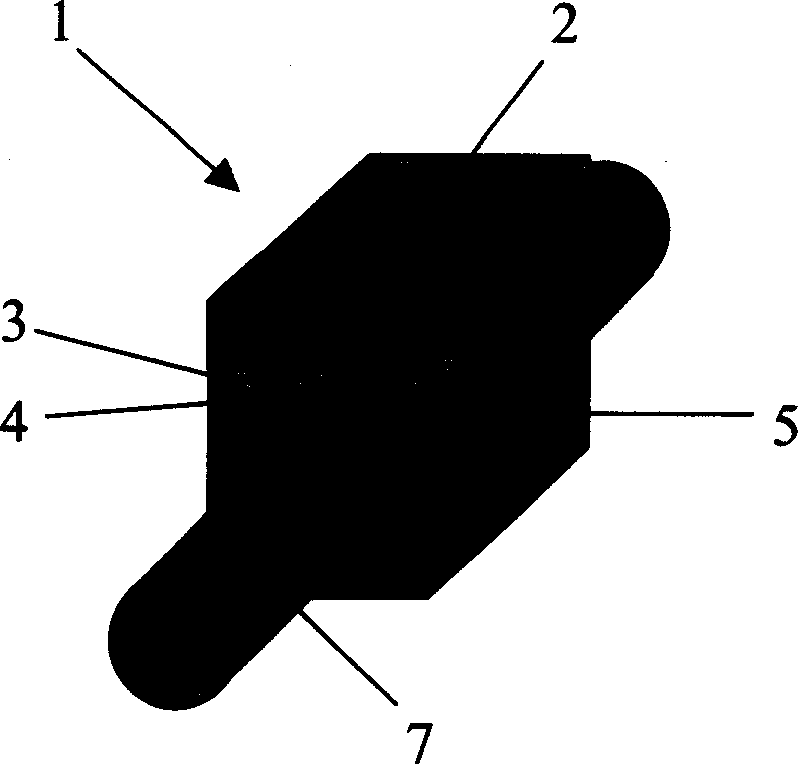

[0029] Fusion reactor splitter plates 1 are fabricated as tiled tiles (see figure 1 ). In a first step, a tungsten sheet 2 of 20 x 40 x 6.5 mm is cut from a tungsten rod with a diameter of 60 mm. Tungsten flakes are cut from tungsten rods in such a way that the height of the flakes (6.5 mm) is parallel to the axis of the rod). In this way, the particles are aligned in the direction of the main heat flow in the future. Then, the intermediate sheet 3 is cut out from a plate made of a tungsten-copper composite material (referred to as T750) with a copper content of 15% by weight, and has a thickness of 2 mm, a width of 20 mm, and a length of 40 mm.

[0030] In a suitable casting system, a tungsten sheet 2, a 0.1 mm thick OHFC copper foil, a T750 intermediate sheet 3 and a 20 x 40 x 10 mm OFHC copper block 4 are stacked. Next, the stack was post-cast with OHFC copper in an inert gas furnace under a hydrogen atmosphere at 1250°C. Hold at this temperature for 30 minutes to ensur...

Embodiment 2

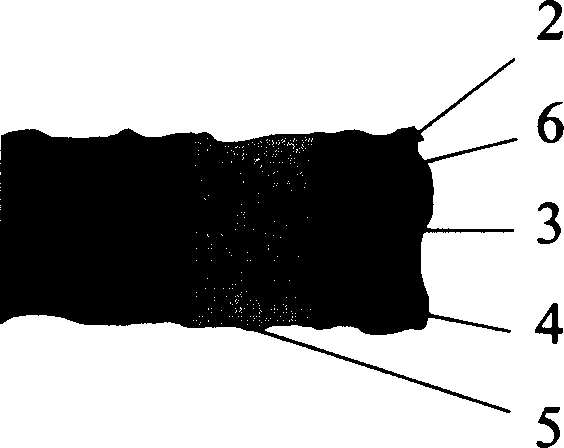

[0035] Figure 4 The splitter plate 1 shown in is fabricated as a monolithic structure in a similar process. A channel with a length of 10 mm and a diameter of 15.2 mm is processed in the center of the tungsten block 2 of 30×20×10 mm.

[0036] The ring 3 with an outer diameter of 15mm, a wall thickness of 1mm and a length of 10mm is made of a plate of tungsten-copper composite material (marked as T800) with a copper content of 20% (weight percent).

[0037] Insert an OHFC copper foil with a thickness of 0.1 mm, a ring 3 made of T800, and an OFHC copper rod with a diameter of 13 mm and a length of 15 mm into a channel machined in a tungsten block, in which the sequence of materials is as follows figure 2 shown. Next, the punches were post-cast with OFHC copper in an inert gas furnace under a hydrogen atmosphere at 1250 °C and kept at this temperature for 30 min. After removing the post-cast monolith, a 12 mm diameter hole was punched in the post-cast copper concentric to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com