Base material for embroidery

A base material and embroidery technology, which is applied in the field of thin materials, can solve problems such as edge stripping and protrusions, and affect the quality of embroidery, and achieve the effect of low cost

Inactive Publication Date: 2004-11-03

冯双桥

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] All kinds of textiles have been used as embroidery substrates for thousands of years. Nowadays, there are more and more kinds of embroidery that use embroidery to reflect and mark brands, and this kind of embroidery is generally done by machines, which makes this kind of embroidery often have edge removal and embossing. The phenomenon of starting up will greatly affect the quality of embroidery

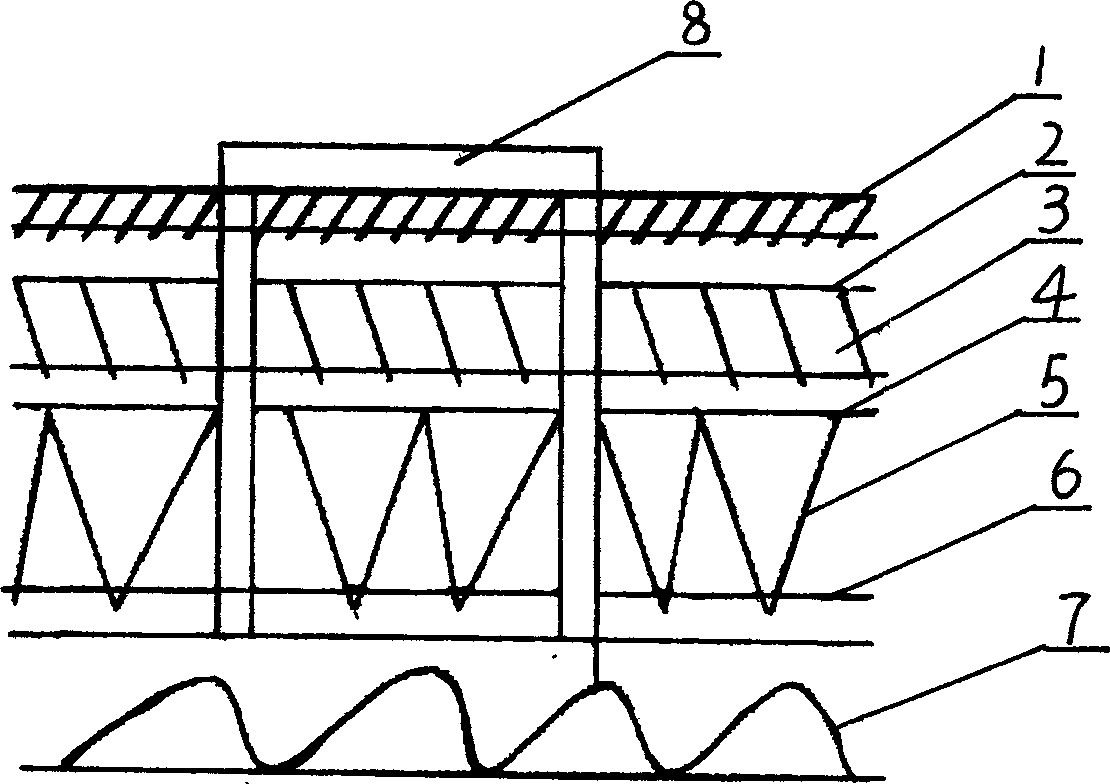

[0003] In order to overcome the phenomenon of off-edges and bulges in embroidery, the purpose of the present invention is to design an embroidery substrate made of multi-layer materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0012] The surface of the textile fabric is covered with a polyethylene film with a thickness of 0.01mm, and the thickness of the other side of the textile fabric is 200g / m 2 paper.

Embodiment 2

[0014] The surface of the non-woven fabric is covered with a PET film with a thickness of 1mm, and a metal sheet is bonded to the other side of the non-woven fabric.

Embodiment 3

[0016] The surface of the wood monolith is too thin with a thickness of 0.5mm polypropylene film, and the other side of the wood monolith is bonded with cloth.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to view more

Abstract

The present invention relates to thin composite material of several kinds of material for, especially, embroidery. The composite material consists of plastic and woven or non-woven fabric, paper sheet or timber sheet, which has polyolefin or PET film of 0.01-1 mm thickness on the upper surface and adhered paper of areal weight 10-200 g / sq m. The present invention has low cost and is suitable for high density embroidery.

Description

technical field [0001] The invention relates to a composite thin material of multi-layer materials, in particular to a base material for embroidery. technical background [0002] All kinds of textiles have been used as embroidery substrates for thousands of years. Nowadays, there are more and more kinds of embroidery that use embroidery to reflect and mark brands, and this kind of embroidery is generally done by machines, which makes this kind of embroidery often have edge removal and embossing. The phenomenon of rising will greatly affect the quality of embroidery. [0003] In order to overcome the edge-off and raised phenomenon of embroidery, the object of the present invention is to design an embroidery substrate made of multi-layer materials. Contents of the invention [0004] The technical solution of the present invention is: the embroidery base material is made of woven cloth or non-woven fabric or paper or wood monomer sheet and plastic, and is characterized in th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B32B7/12

Inventor 冯双桥

Owner 冯双桥

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap