Polishing agent for alkaline non-cyanide zincate zinc plating and process for preparing polishing agent composition

A cyanide zincate and brightener technology, which is applied in the field of composition brighteners and electro-galvanized brighteners, can solve problems such as unsatisfactory effects, and achieve the effects of low cost, convenient use, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

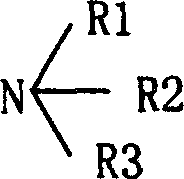

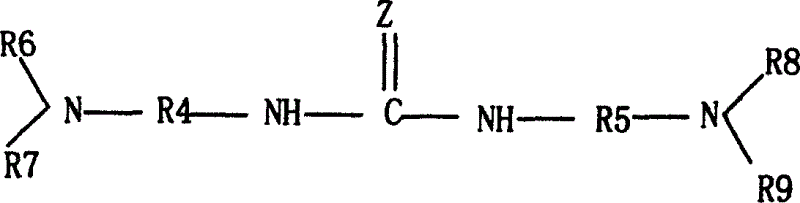

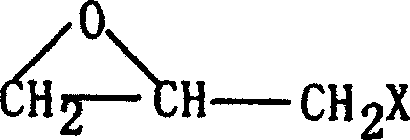

Method used

Image

Examples

Embodiment 1

[0050] In the reactor, add 13.6g imidazole, 15.7g diethanolamine, 20.2g N,N'-bis(N,N-dimethylaminoethyl)urea, 200ml water (the water added at this time should be able to fully dissolve the added compound), heated to 50°C, added dropwise 55.6g of epichlorohydrin, and the dropwise addition time was 40 minutes, and the temperature was controlled below the reflux temperature. After adding the epichlorohydrin, the temperature was raised to reflux temperature of 95°C, Keep it warm at this temperature for 8 hours, cool it down, and recover it to obtain the galvanized brightener.

Embodiment 2

[0052]In the reactor, add 16.2g 2-methylimidazole, 22.4g triethanolamine, 23g N, N'-bis(N,N-dimethylaminopropyl) urea, 200ml water, heat up to 60°C, and start to drop 64.8g of epichlorohydrin, the dropping time is 60 minutes, and the temperature is controlled below the reflux temperature. After the dropping is completed, the temperature is raised to 95°C, and kept at this temperature for 10 hours, cooled, and recovered to obtain galvanized brightener.

Embodiment 3

[0054] In the reactor, add 16.2g 2-methylimidazole, 17.8g N-methyldiethanolamine, 24.6g N, N'-two (N, N-dimethylaminopropyl) thiourea, water 200ml, be warmed up to At 70°C, start to add 55.6g of epichlorohydrin dropwise. The dropwise addition time is 40 minutes. Recycled to obtain galvanized brightener.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polymerization | aaaaa | aaaaa |

| Polymerization | aaaaa | aaaaa |

| Polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com