Antiscaling treatment and purification method for water drain pipes

A technology for drainage pipes and anti-scaling, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc. The hidden danger of blocking accidents, the difficulty of cleaning, and the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

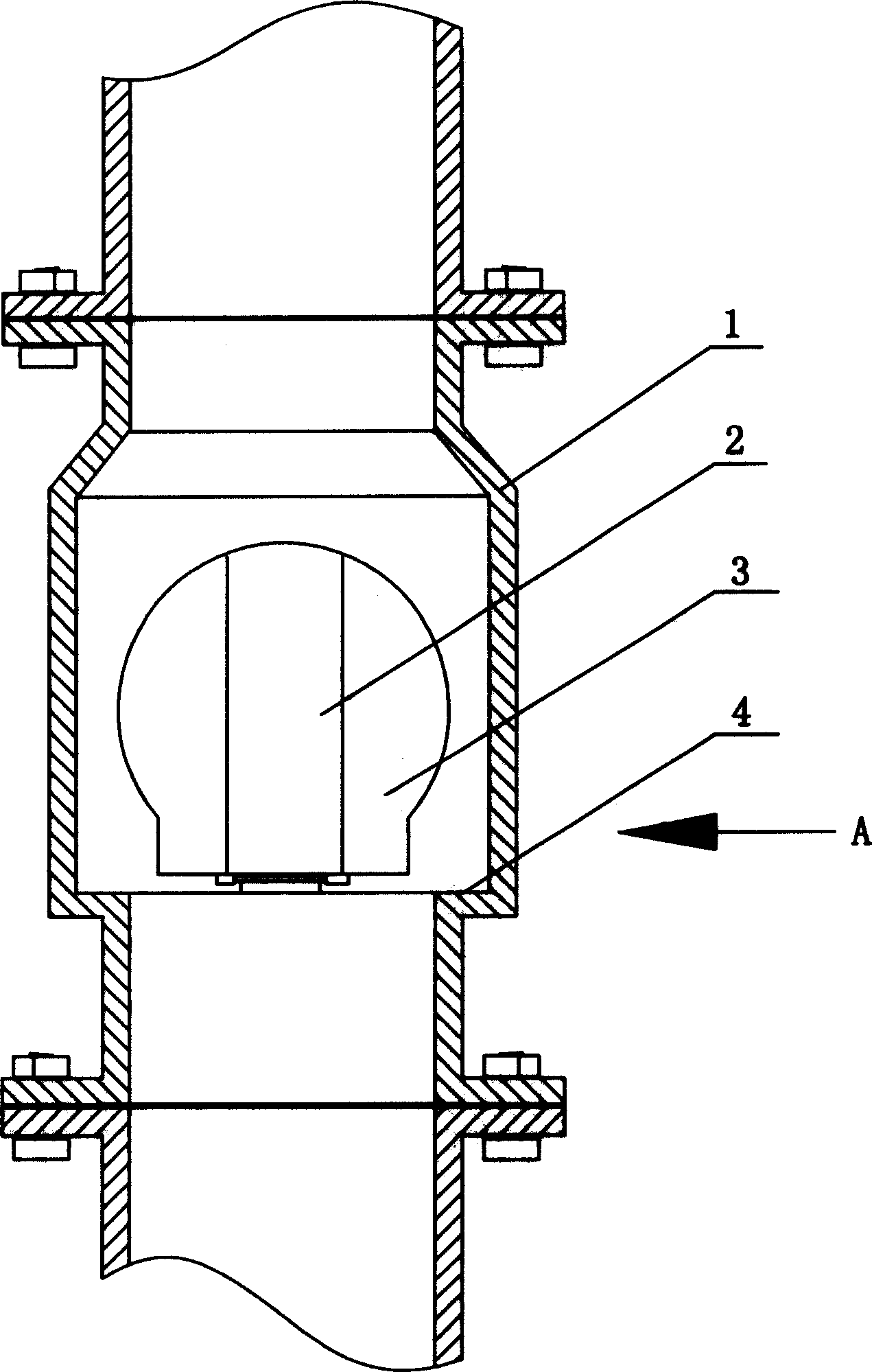

Embodiment 1

[0020] Example 1 The entrance of the lower end of the mine drainage system is a drainage pump, and then a pig launching chamber, a non-resistance check valve and a drainage pipeline are installed in sequence, as shown in the figure, the non-resistance check valve is a valve housing connected to the pipeline 1. The valve plate 3 is composed of the valve seat 4 set on the valve casing. The one-way opening valve plate is hinged on the valve seat. When the valve plate is closed, the lower end surface of the valve plate matches the valve seat. The maximum opening degree of the valve plate is 90°, the upper end surface of the valve plate is provided with a spring 5 perpendicular to the valve plate surface, the spring ensures that the valve plate returns to 70° when the opening angle reaches 90°, and an elastic spring is set on the lower end surface of the valve plate of the non-resistance check valve. Nylon protective layer2. First, use a pig to remove and clean the possible foreign...

Embodiment 2

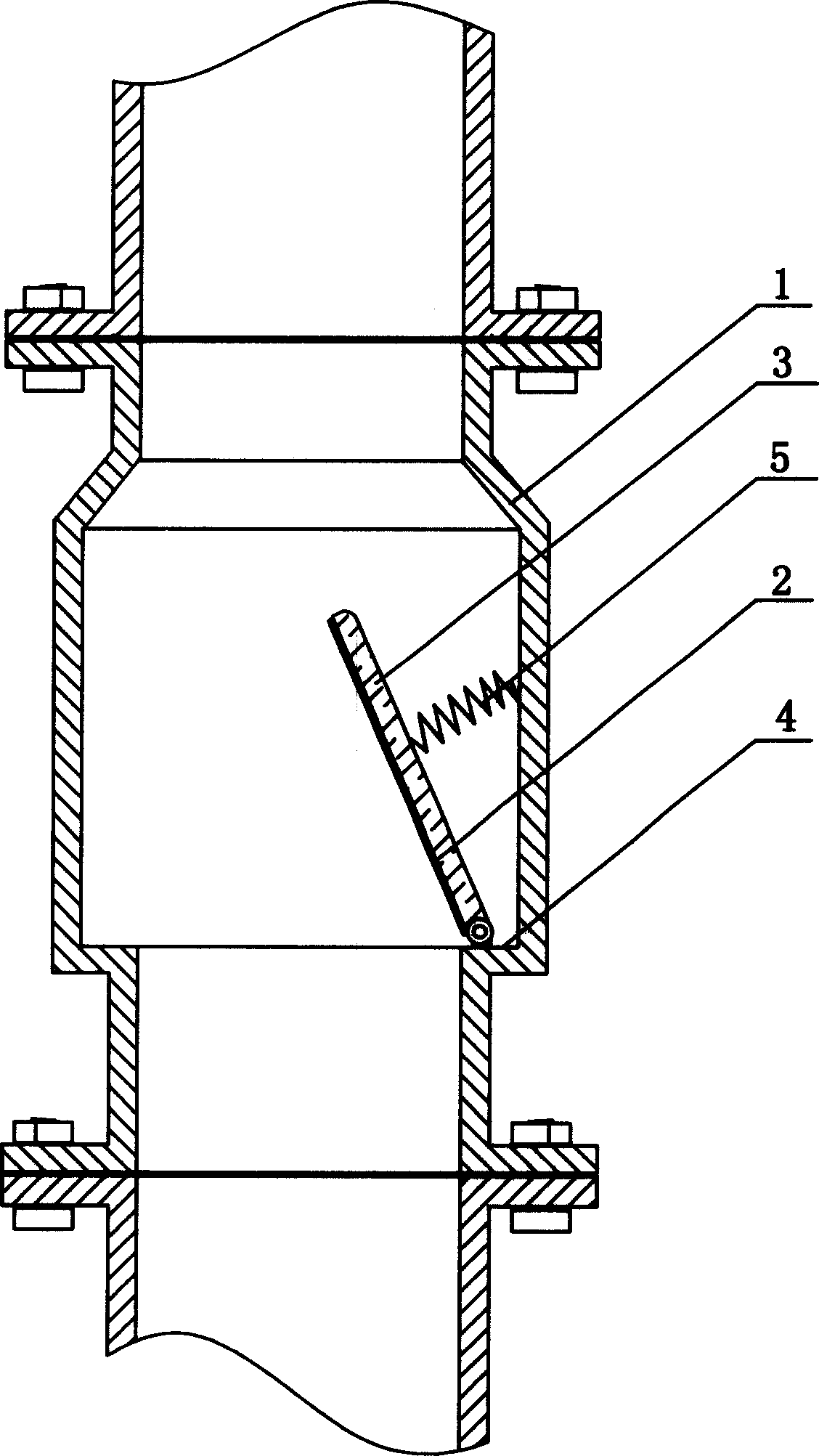

[0021] Example 2 When the industrial drainage pipeline is installed, the lower end of the drainage pipeline is provided with a drainage pump, a pig launching chamber and a non-resistance check valve in sequence. As shown in the figure, the non-resistance check valve is composed of a valve casing connected to the pipeline 1. The valve plate 3 is composed of the valve seat 4 set on the valve casing. The one-way opening valve plate is hinged on the valve seat. When the valve plate is closed, the lower end surface of the valve plate matches the valve seat. The maximum opening degree of the valve plate is 90°, the upper end surface of the valve plate is provided with a spring 5 perpendicular to the valve plate surface, the spring ensures that the valve plate returns to 70° when the opening angle reaches 90°, and an elastic spring is set on the lower end surface of the valve plate of the non-resistance check valve. Rubber protective layer2.

[0022] The water outlet of the pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com