Process for the separation of paper-plastic composite material

A composite material and separation method technology, applied in the field of separation of paper-plastic composite materials, can solve problems such as inability to separate, plastic cannot be degraded, and paper-plastic composite bags cannot be directly processed, so as to solve environmental problems, huge economic benefits and social benefits. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

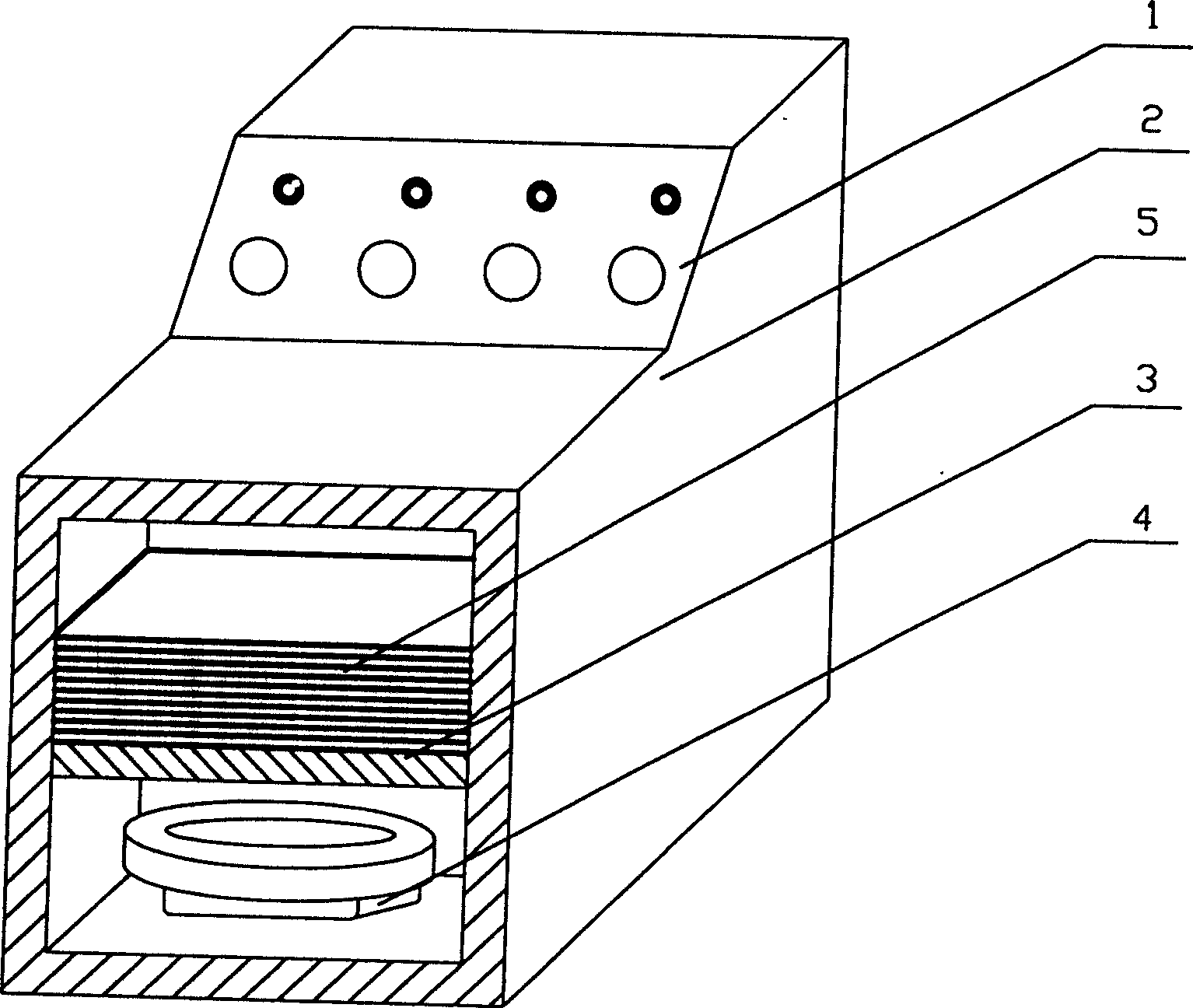

[0009] As shown in the drawings, its structure is composed of a separation device body 2, a heating plate 3, and a heater 4; a control panel 1 is installed on the upper end of the separation device body 2; a steel heating plate 3 is installed in the separation device body 2 , an electric heater 4 is installed at the lower end of the heating plate 3 . Its working principle is as follows: First, cut the two sides of the waste paper-plastic composite material bag, and cut the bottom edge to form two plane paper-plastic composite materials. Then a stack of about 20 paper-plastic composite materials is put into the upper end of the heating plate 3 in the separation device body 2 . Then operate the control panel 1. If the paper-plastic composite material is relatively thin, control the operating temperature to about 180°C and heat it for 30 seconds. At this time, through human observation, it is found that the last piece of plastic shrinks and can be pulled out. Make the above pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com