Operation method of externally pressurized hollow fiber membrane separator

The technology of a separation device and an operation method, applied in the field of membrane separation, can solve the problems of many pipelines, complicated operation and unclean chemicals, etc., and achieve the effects of membrane flux recovery, good cleaning effect and simple operation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

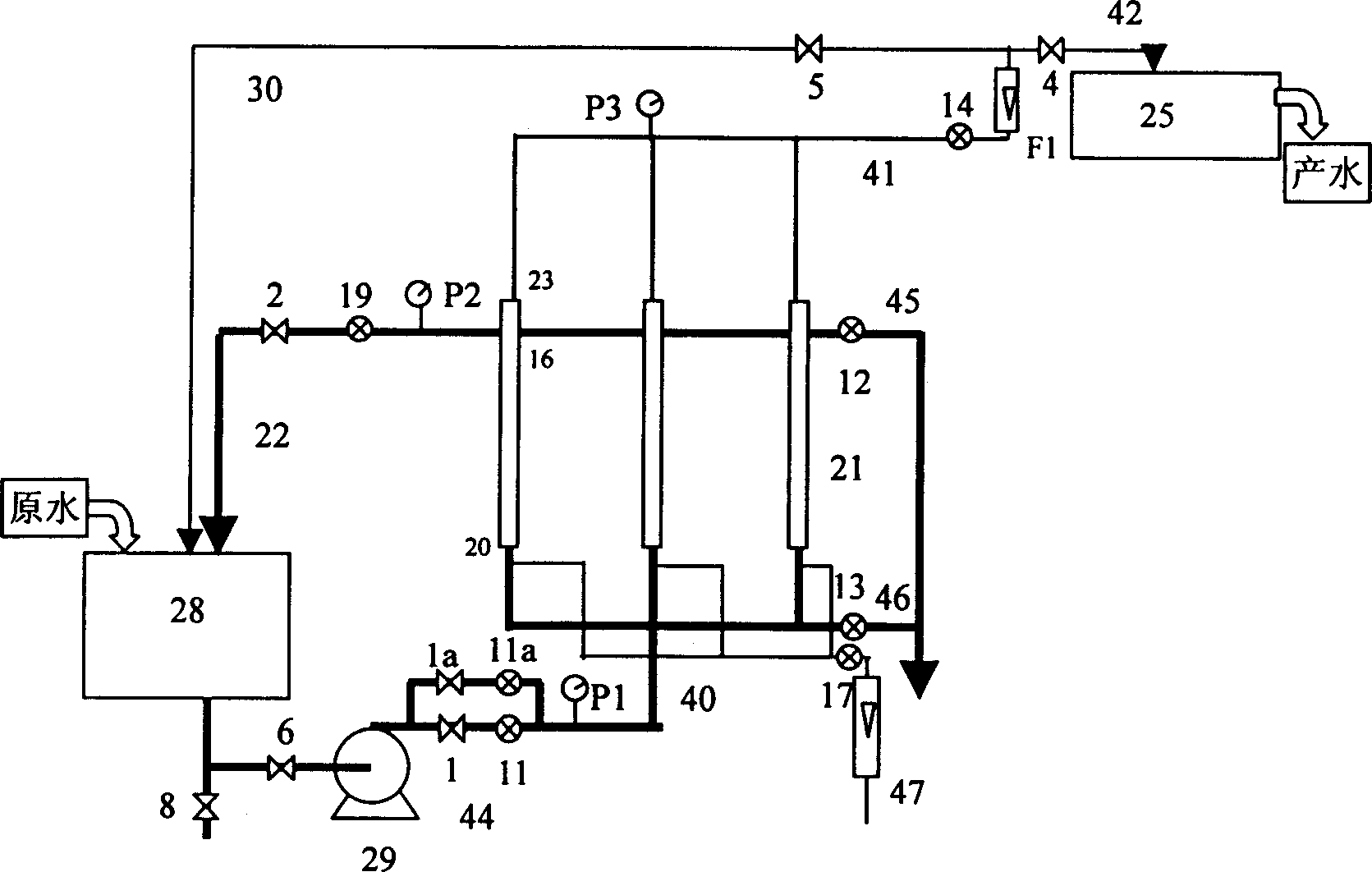

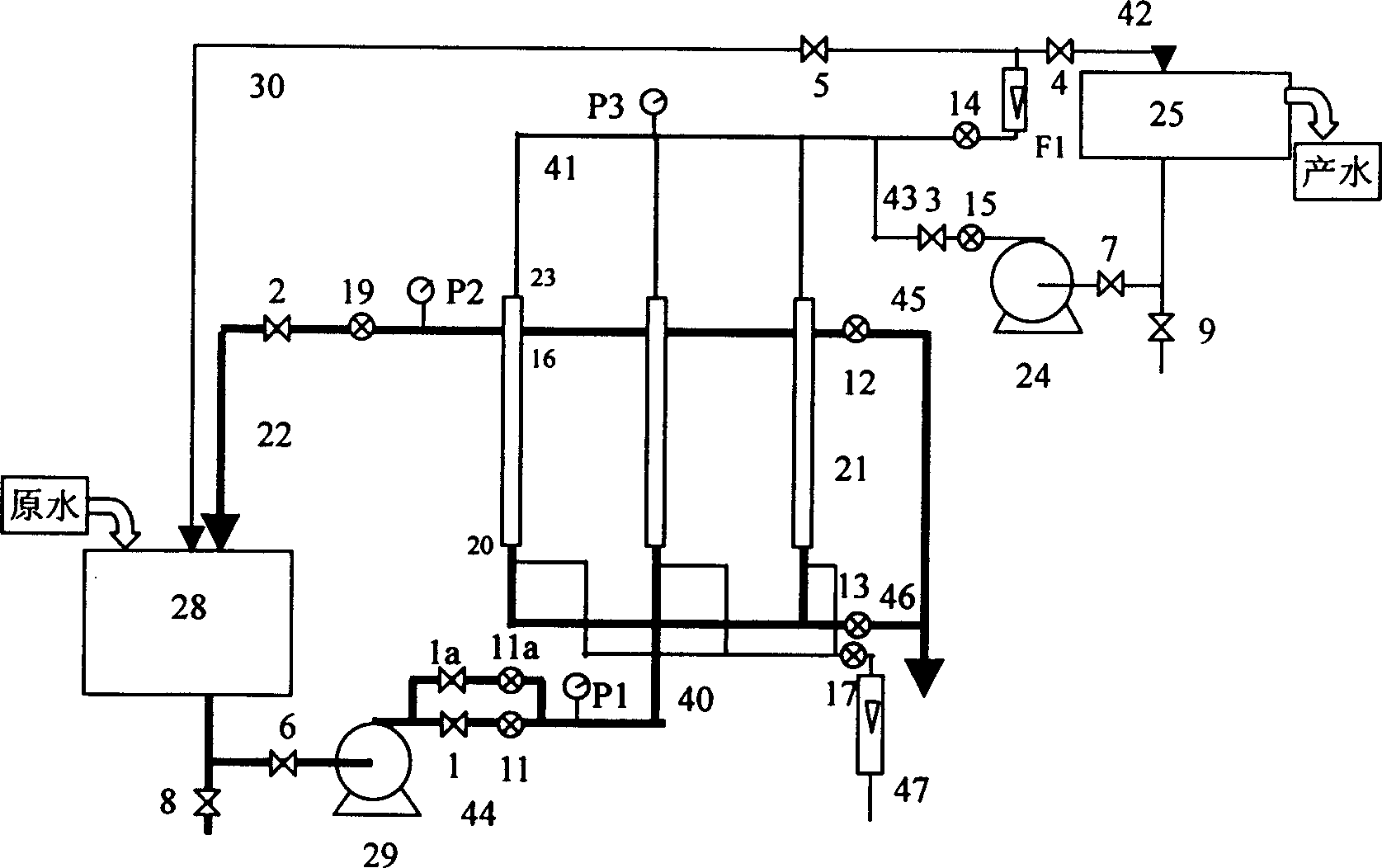

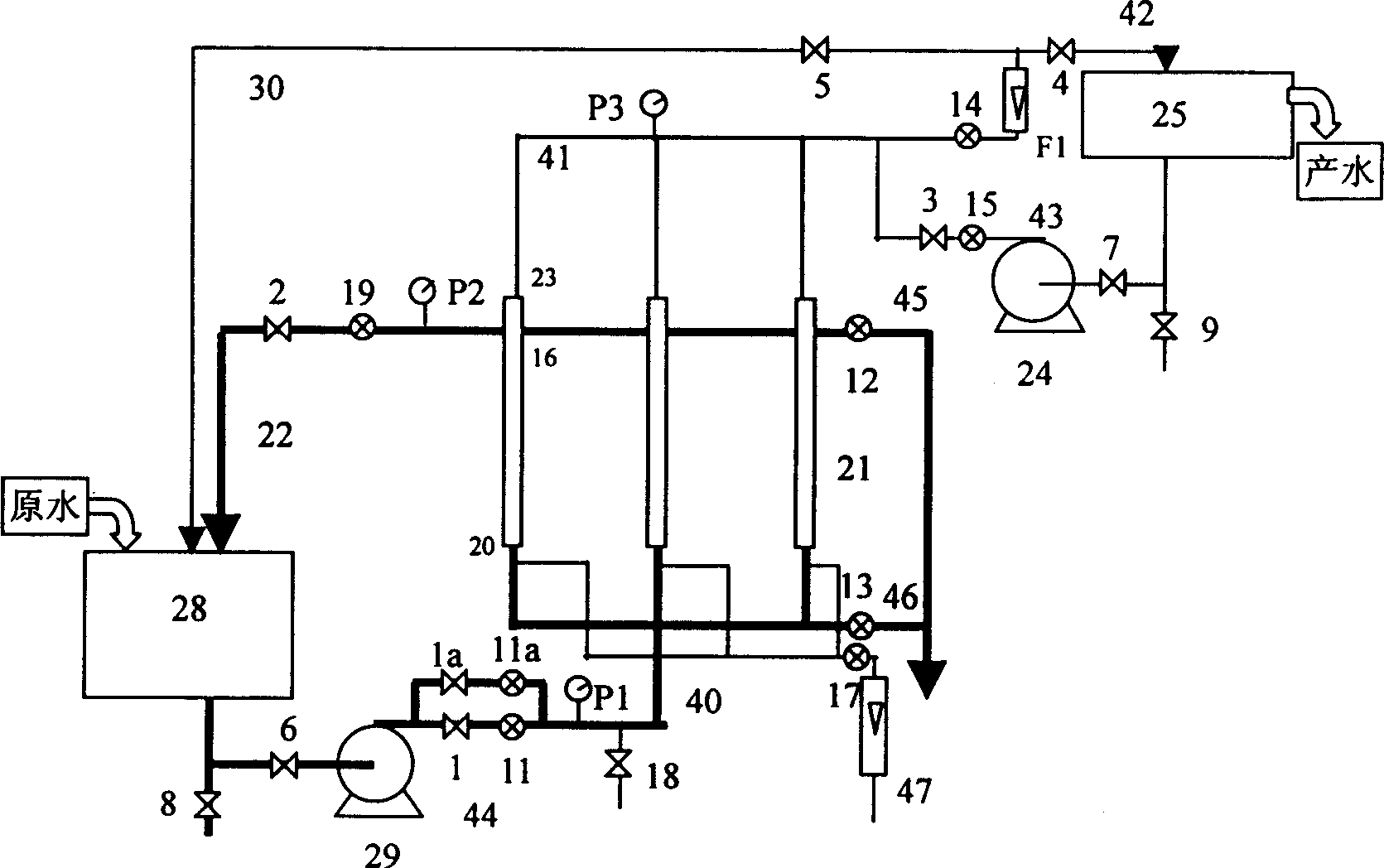

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] The device of the present invention is provided with a plurality of valves, and the operation, cleaning and sewage discharge of the membrane module are controlled by controlling the opening and closing of the valves. The valves in the drawings can be divided into manual valves and automatic valves (which can be pneumatic or electric diaphragm valves, butterfly valves, and ball valves) according to their types.

[0023] If divided according to function or function, valves 1 and 1a are inlet pressure regulating valves or regulating valves; valves 11 and 11a are called import automatic valves; valve 2 is outlet pressure regulating valves or regulating valves; valve 19 is called outlet automatic valves; 4 and 5 are switching valves, which are used for switching between membrane separation work and chemical cleaning work; valve 6 is the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com