Cutoff wheel for hand power tools

A cutting disc and function technology, applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of reducing cutting function, disturbing vibration, unevenness, etc., and achieving the effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

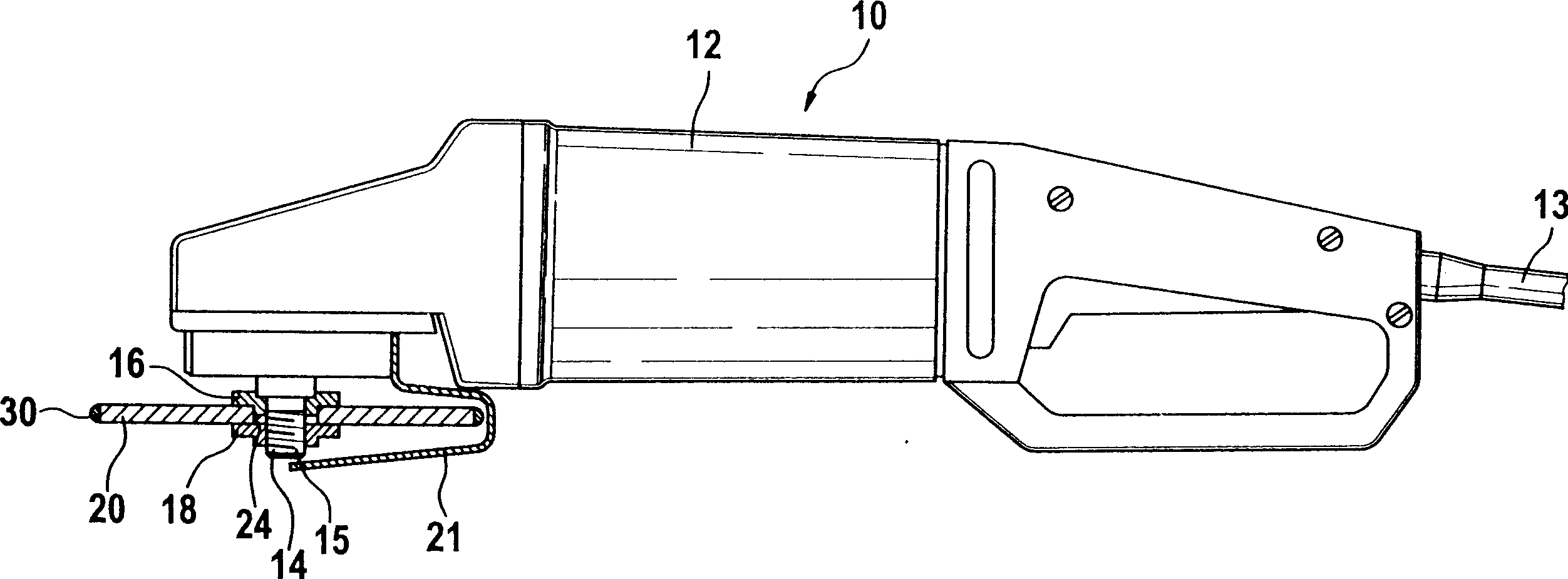

[0019] exist figure 1 The portable grinding tool shown in side view in FIG. 1 is designed as an angle grinder 10 . This grinding machine (Winkelschleifer) has an elongated machine housing 12, is provided with a handle not shown in detail at its rear end, stretches out a connecting cable 13 from the free end of this handle, is used for not shown out of the motor power supply.

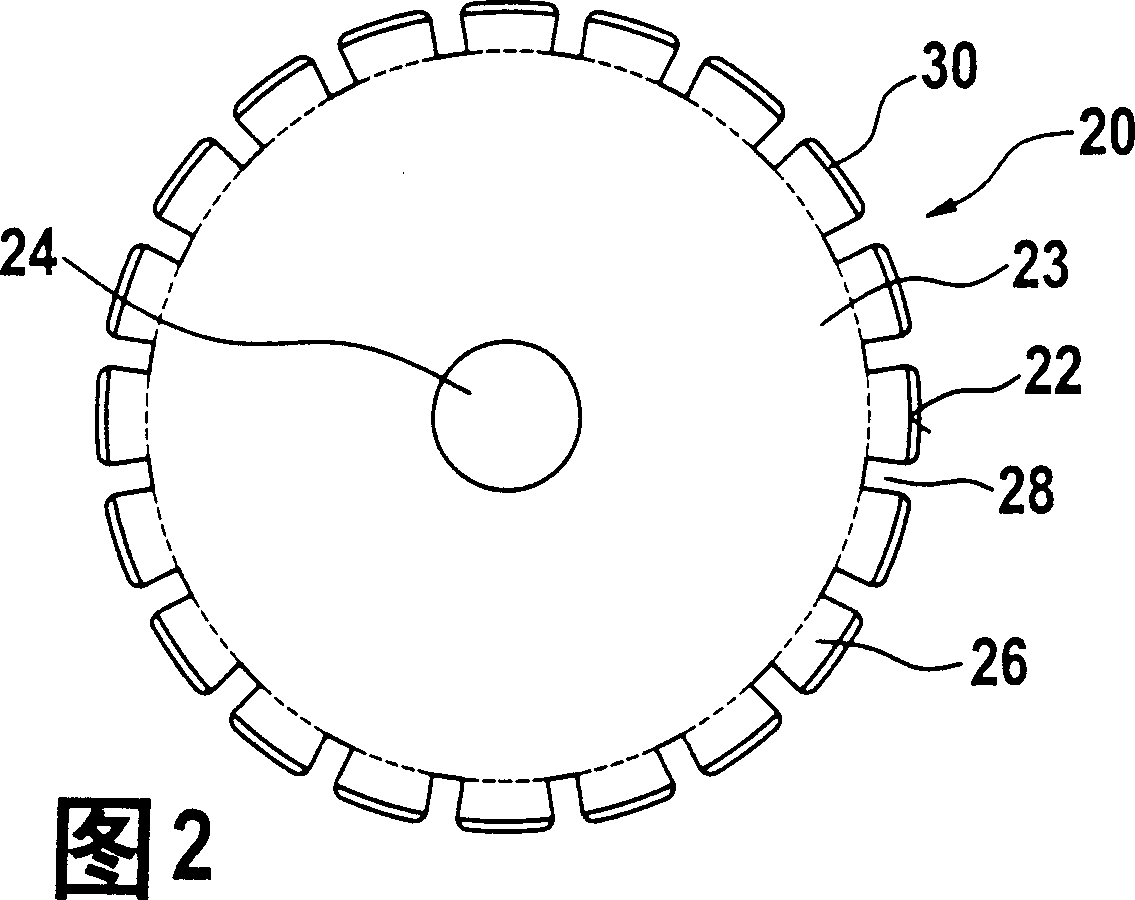

[0020] In the area of the handle, a switch key (not shown in detail) is conveniently provided for switching on and off the electric motor (not shown). At the front end of the housing 12 , the housing has a working spindle 14 extending perpendicularly to the longitudinal direction of the machine housing 12 and serving to rotate a cutting disc 20 clamped in a non-rotatable manner. The cutting disk 20 is inserted on the working spindle 14 with its central hole 24 in such a way that the working spindle passes through the cutting disk 20 so that a clamping nut 18 can be screwed into its thread 15 at the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap