Leathe shoe upper pattern curvature treatment method

A processing method and technology of zigzag, applied in the field of sample zigzag processing, can solve the problems of wasting manpower, material resources and time of designers, intricate processing methods of zigzag, poor design effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

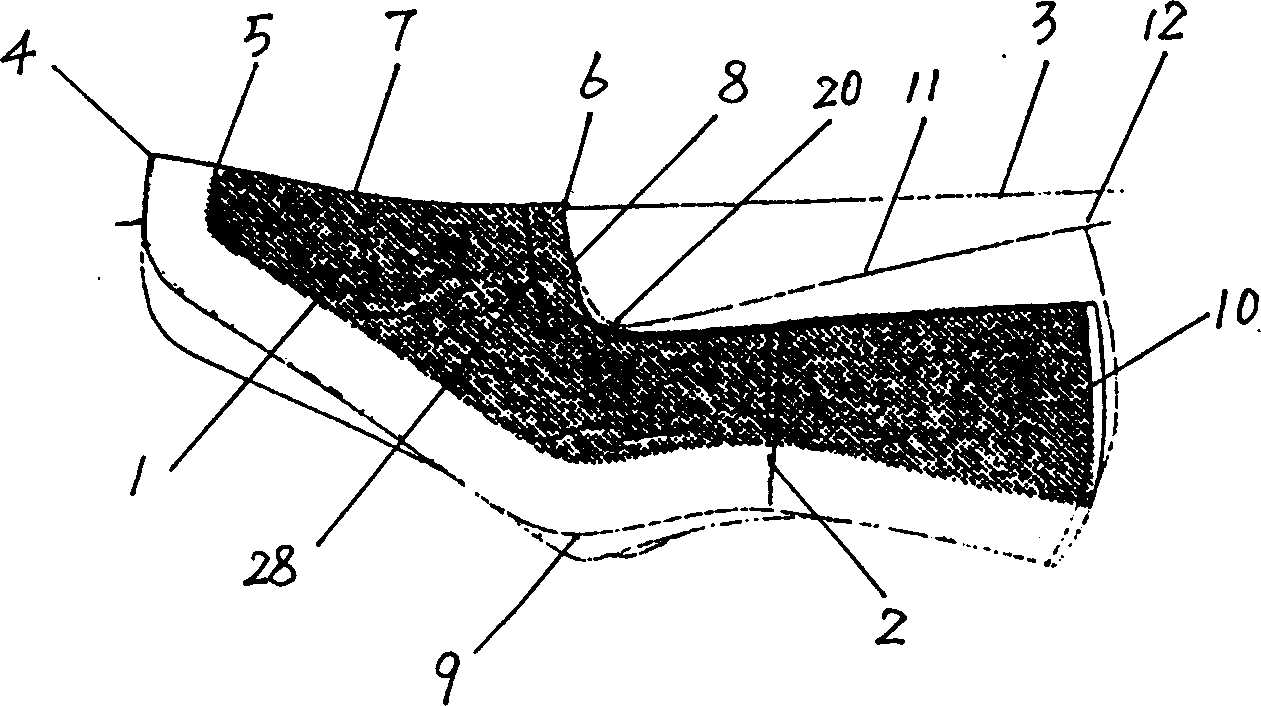

Embodiment 1

[0225] The style structure of the leather shoes is a shallow mouth type, the upper structure is an integral type, and the heel height is 60 mm. Adopt the above-mentioned first kind of shallow-integrated curved stilt processing method, wherein: the distance between the shoe mouth buckle and the cut is 3 mm from the bottom mouth line; The buckle point is located 6mm from the heel point to the front side; the inner pocket is 6mm apart.

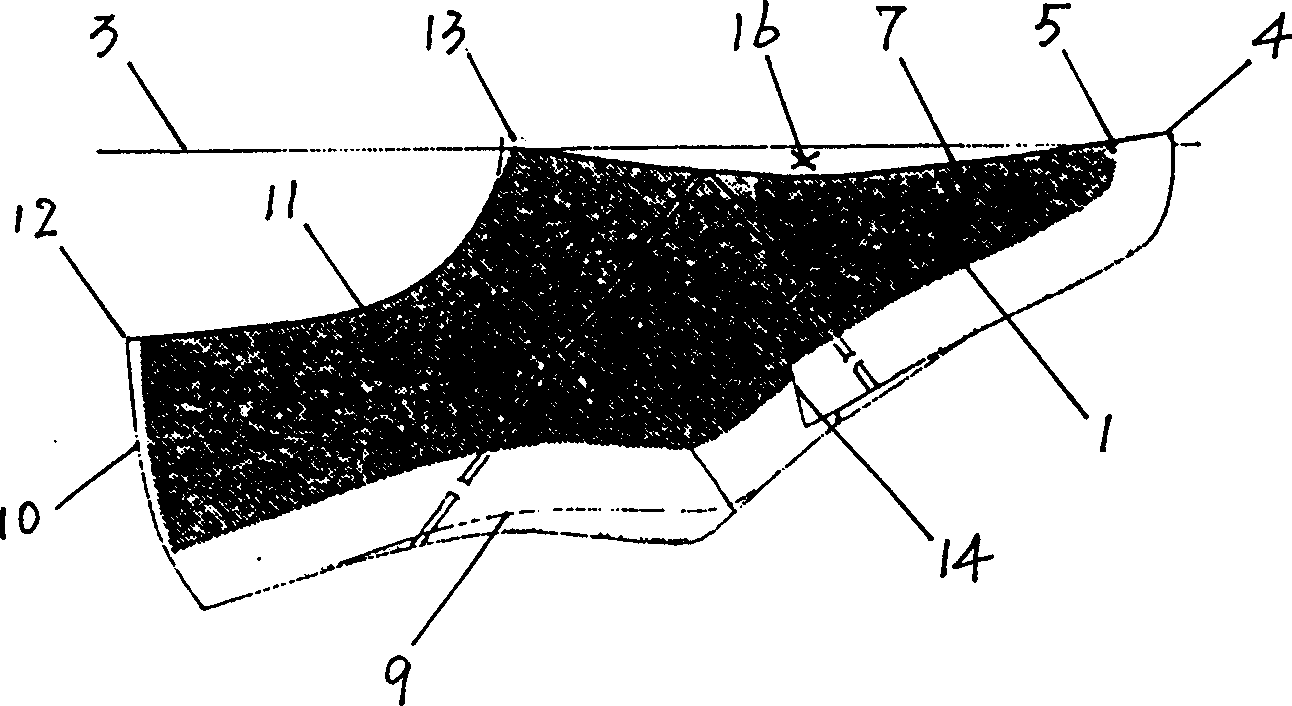

Embodiment 2

[0227] The style structure of the leather shoes is the deep mouth type, the upper structure is the shovel type, and the heel height is 50 mm. Adopt the above-mentioned third kind of deep-integrated curved stilt processing method, wherein: the corner-cut margin of the shoe mouth notch is 5 millimeters;

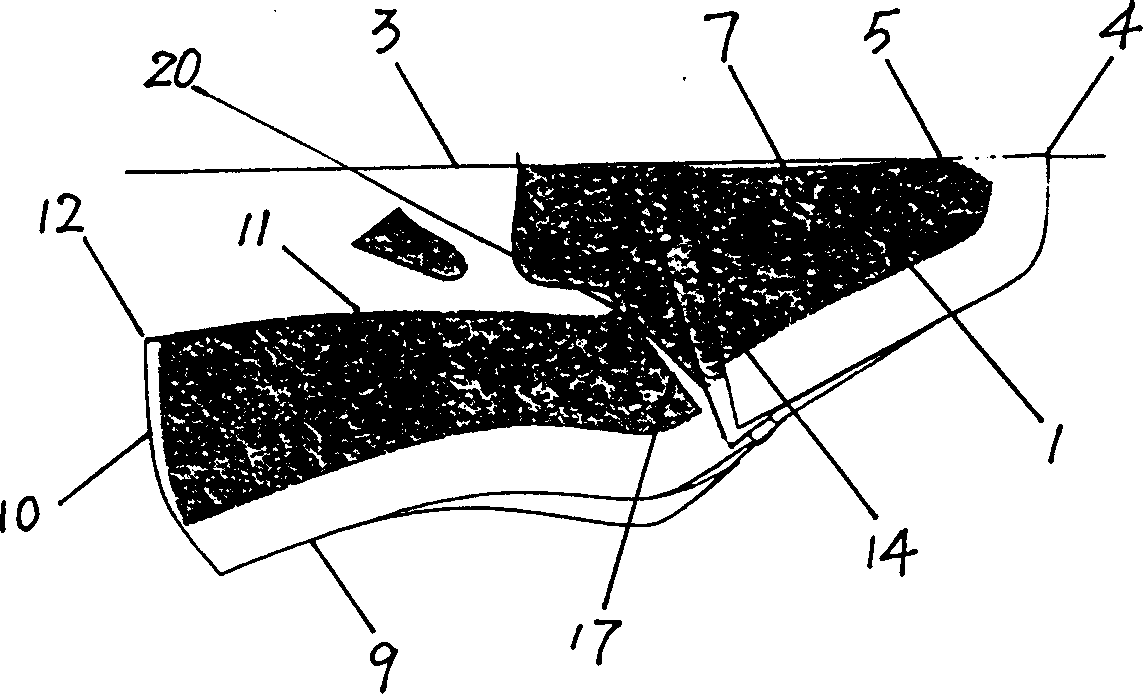

Embodiment 3

[0229] The style structure of the leather shoes is the outer ear type, the upper structure is the joint type, and the heel height is 80 mm. Adopt the above-mentioned sixth external splicing method of curved stilts, wherein: when the curved stilts are flattened, the maximum distance between the back midline and the folded midline is kept at 5 mm; the inner cups are divided into 8 mm; The maximum distance between the dorsal midline of the two splicing parts is 3 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com