Production method of transparent monocrystal sugar

A single crystal rock sugar and production method technology, applied in the field of transparent single crystal rock sugar production, can solve problems such as uneven product size, inconsistent product color, and irregular shape, and achieve the effects of shortened production time, uniform specifications, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] Specific embodiments are not limited to the following embodiments

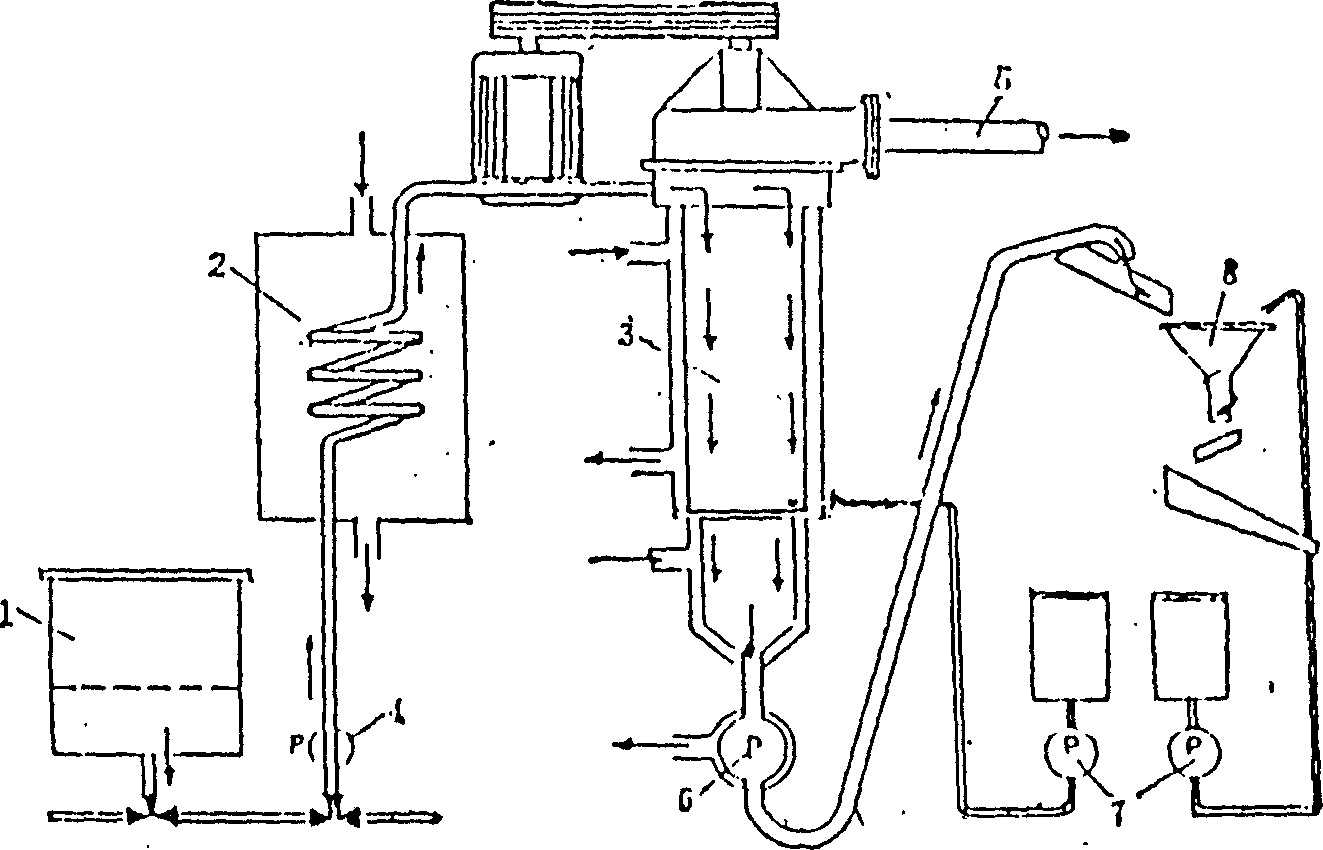

[0019] As shown in Figure 1, the traditional continuous vacuum film sugar cooking device consists of a syrup storage tank 1, a preheater 2, a film sugar cooking machine 3, a syrup pump 4, a vacuum system 5, a discharge pump 6, pigments, acids and spices metering pumps 7. Composition of 8 mixers.

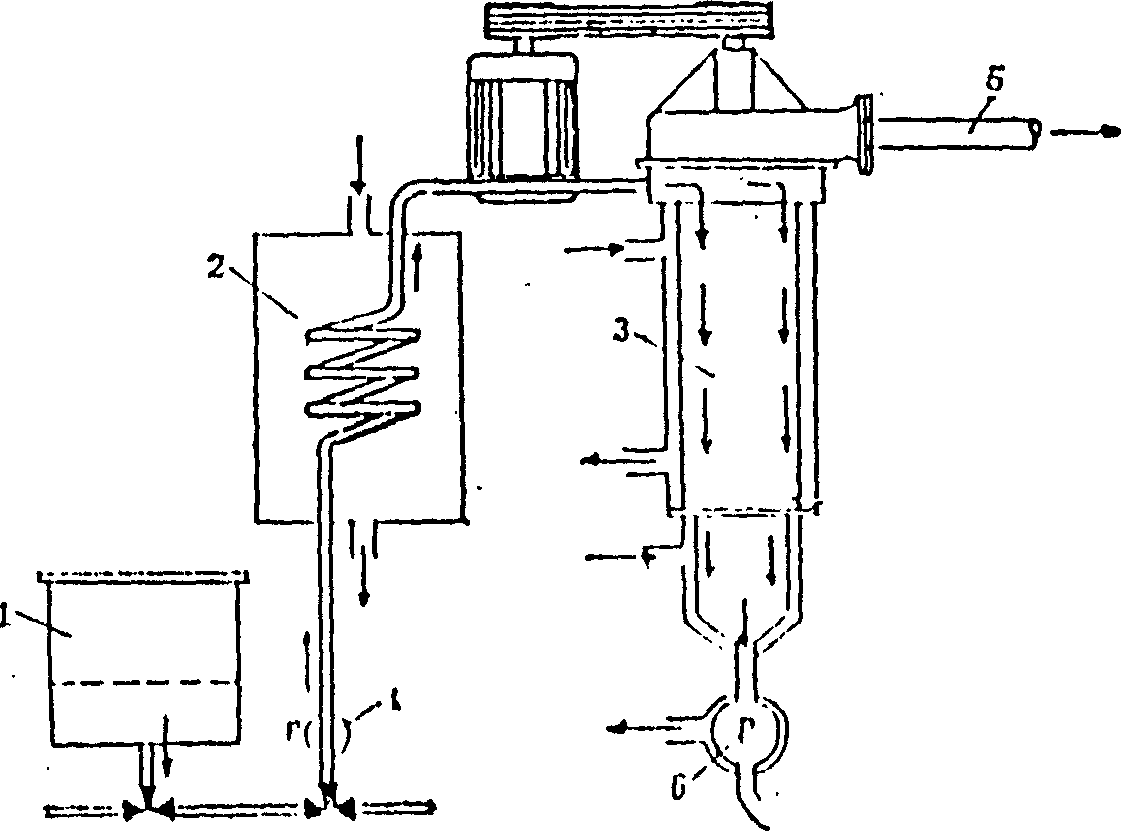

[0020] As shown in Figure 2, the continuous vacuum film sugar boiling device is composed of a syrup storage tank 1, a preheater 2, a film sugar boiling machine 3, a syrup pump 4, a vacuum system 5, and a discharge pump 6.

Embodiment 1

[0022] Raw material composition 92% white granulated sugar, 8% high fructose syrup.

[0023] Add 20% - 40% water to the raw sugar, heat and stir continuously to fully dissolve the sugar. When the sugar solution is heated to 105°C and the concentration is 75%, the sugar solution should be allowed to stand still for 1.5 minutes after boiling to fully dissolve the white sugar. , the melted sugar solution is filtered immediately, the mesh screen can be 20 mesh, the filtered sugar solution enters the syrup storage tank 1, the temperature of the sugar solution is 105 ℃, the concentration is 75%, and it is quantitatively sent into the serpentine by the piston type syrup pump 4. When the copper tube is heated at the bottom inlet, the sugar liquid in the heating tube is continuously vaporized to form a vapor-liquid mixture, which rises along the heating tube. During the rising process, the evaporation continues, and the pressure drops to cause the volume to expand rapidly, and the risi...

Embodiment 2

[0025] Raw material composition 93% white granulated sugar, 7% high fructose syrup.

[0026] Add 30% water to the raw sugar, heat and stir continuously to fully dissolve the sugar. When the sugar solution is heated to 106°C and the concentration is 80%, the sugar solution should be left still for 2 minutes after boiling to fully dissolve the white sugar. Immediately filter the sugar solution, the mesh screen can be 140 mesh, the filtered sugar solution enters the syrup storage tank 1, the temperature of the sugar solution is 106 ° C, the concentration is 77%, and the piston type syrup pump 4 is quantitatively sent to the serpentine copper tube for heating. At the bottom inlet, the sugar liquid in the heating tube is continuously vaporized to form a vapor-liquid mixture, which rises along the heating tube. During the rising process, the evaporation continues, and the pressure drops to cause the volume to expand rapidly, and the rising speed becomes faster and faster, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com