Full-glass vacuum solar heat collection tube and manufacturing technology thereof

A heat collecting tube and all-glass technology, which is applied to the field of all-glass vacuum solar heat collecting tubes, can solve the problems of increasing manufacturing process and production cost, stress concentration of sealing and junction, difficulty in setting exhaust pipe, etc., and achieves reduction of manufacturing process and simplification of structure. , the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in more detail below in conjunction with the accompanying drawings and preferred embodiments.

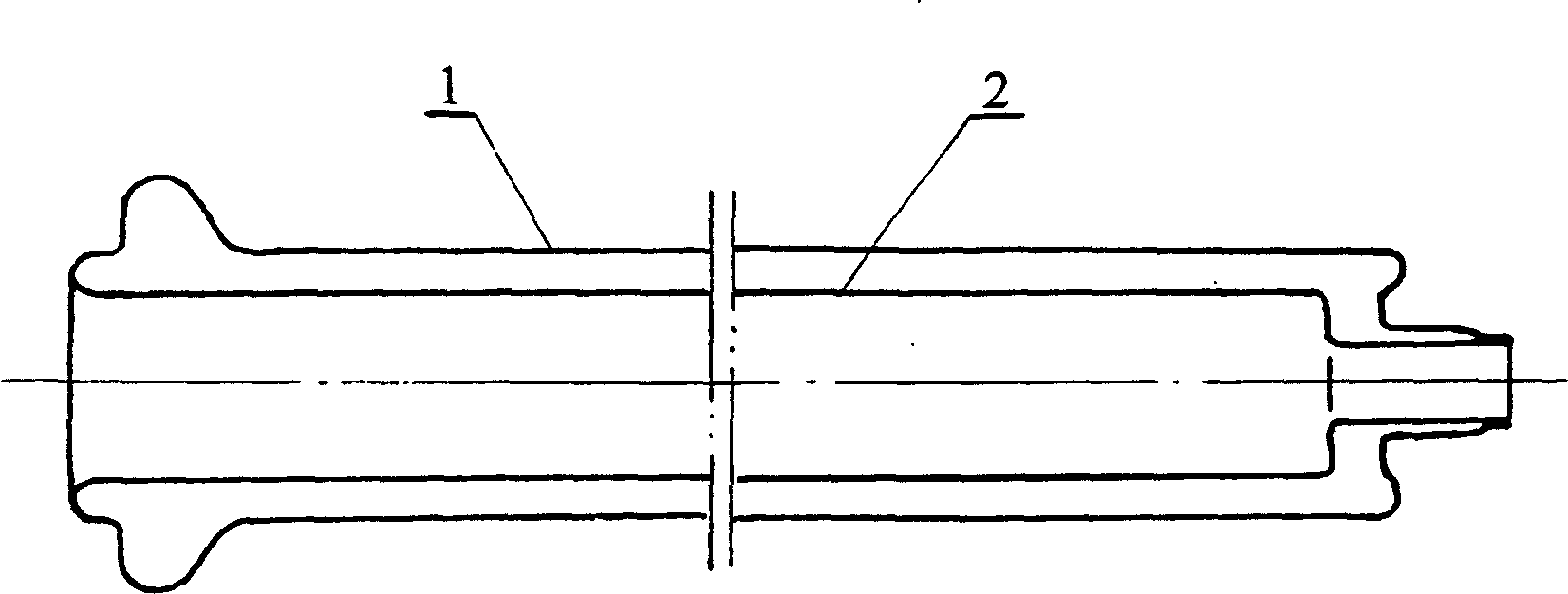

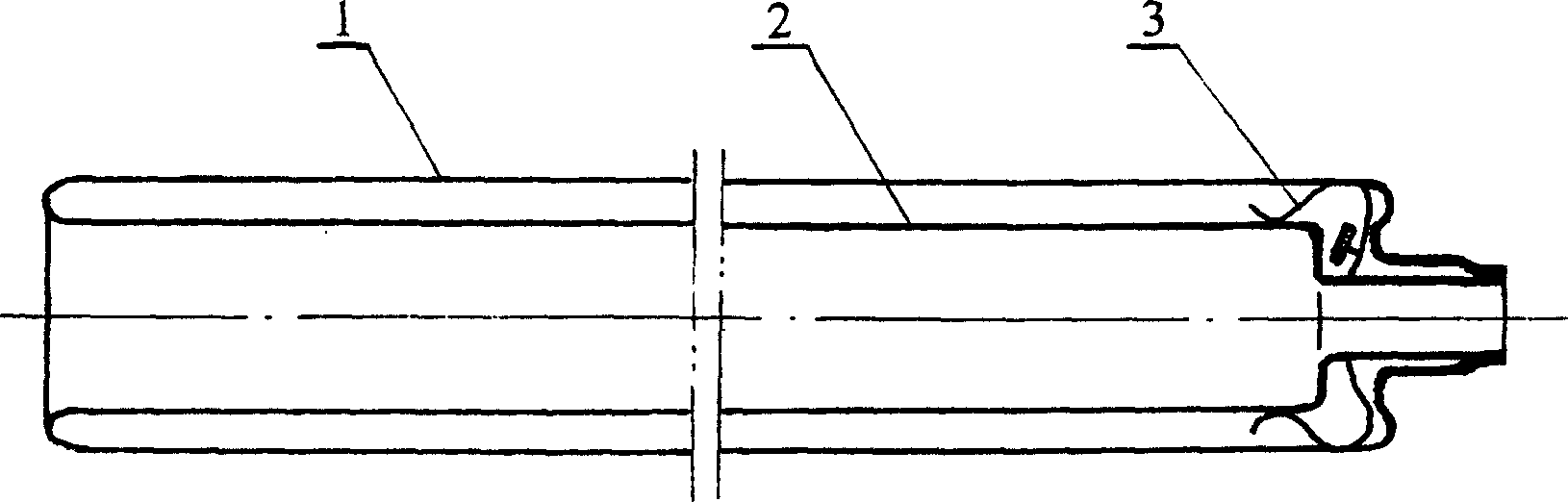

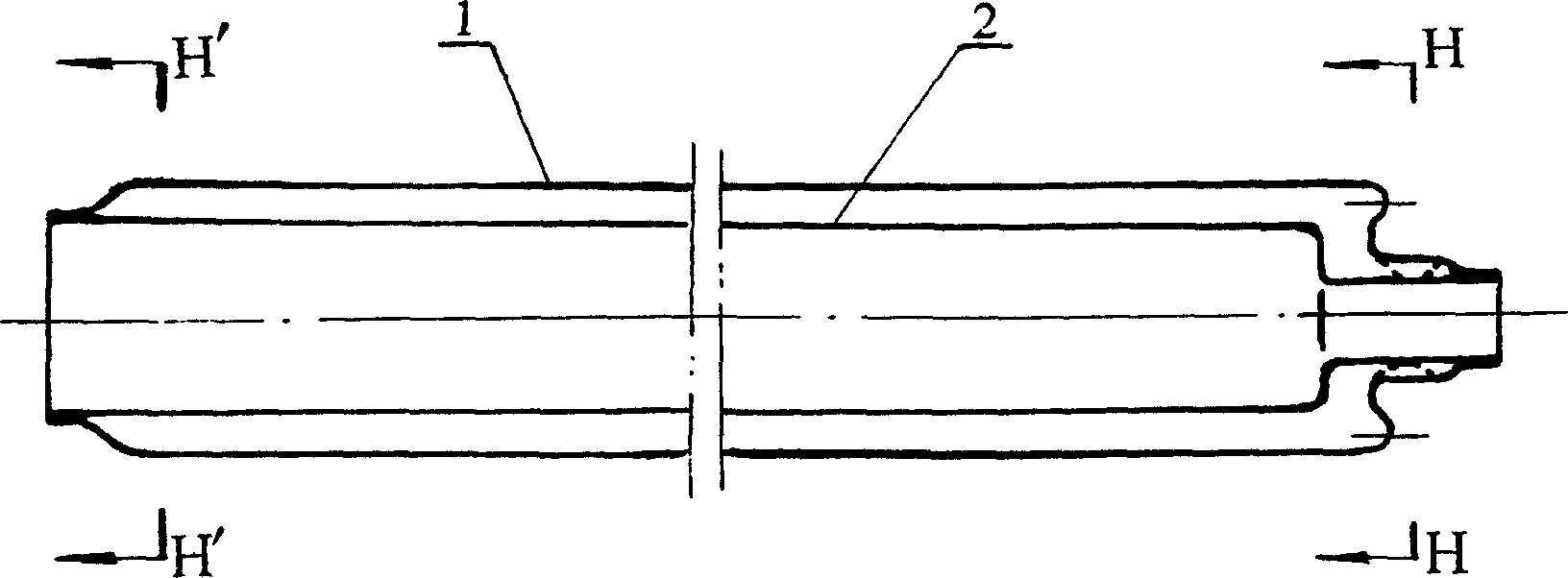

[0030] Such as Figure 1~3 As shown, the composition of the straight-through all-glass vacuum solar collector tube of the present invention includes an outer glass tube 1 and an inner glass tube 2; the outer glass tube 1 is a transparent glass tube, and the outer surface of the inner glass tube 2 is attached with a selective solar absorbing coating , or the whole tube is directly made of heat-absorbing glass; the inner and outer tubes are ring-sealed together along the nozzle to form a lumen with openings at both ends; the interlayer between the two tubes is in a vacuum state after exhaust; in order to improve its Vacuum degree, support 3 with getter can be installed in the interlayer.

[0031] It is characterized in that: at least one of the two ends of the heat collecting tube is a special-shaped end with the following structure (for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com