Process of elasticity thickness optimiztion for biologic ferment tank batch procedure

A technology of biological fermentation and optimization method, which is applied in the biological field and can solve the problems of determining the time to stop the batch of tanks and the like

Inactive Publication Date: 2005-01-05

SHANGHAI JIAO TONG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The scheduling optimization method described in this paper can determine the next tank batch to be shut down in advance, but the tank stop time of the tank batch is limited to a given time in advance, and does not determine the time of the tank batch to be shut down according to the actual situation at that time. The best stop moment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] Object: A penicillin manufacturing workshop with 18 fermenters of 100 cubic meters running in parallel, with an average fermentation period of 216 hours, an off-line sampling period of 4 hours, and a predetermined tank stop time interval T d = 12 hours. The test samples were randomly selected 58 batches of industrial production tanks.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

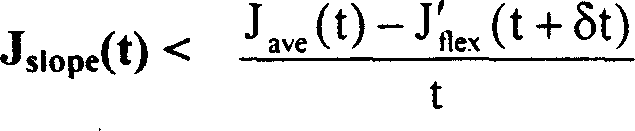

The invention is an elastic control optimizing method for bio-fermentation batch course. On the condition of ensuring the top-bottom working segments and load stable, firstly determining an elastic control interval for the cylinder batch to be stopped, where the optimum time of stopping cylinder batch is; then making on-line calculation of an elastic control function of the cylinder batch in this interval, where the function quantitatively gives the benefit-making potential of the cylinder batch relative to average cylinder batch; and finally according to the function, implementing the object of the maximum economic benefits and applying the policy of elastically stopping cylinder to determine the optimum cylinder batch-stopping time. It stops low-benefit and -potential cylinder batch in advance, thus reducing economic losses; prolonging high-benefit and -potential cylinder batch, increasing economic benefits and finally on the condition of not increasing production cost, increasing the total economic benefits of a whole workshop.

Description

technical field [0001] The invention relates to an optimization method for biological fermentation, in particular to an elastic scheduling optimization method for a biological fermentation batch process, and belongs to the field of biological technology. Background technique [0002] The biological fermentation batch process is an important industrial production process, providing medicines (antibiotics, genetic engineering recombinant drugs, vaccines, vitamins, etc.), food and feed additives (various amino acids, nucleic acids, etc.) and other products related to the national economy and people's livelihood (alcoholic beverages, soy sauce and vinegar, biological health care products). The typical characteristics of biological fermentation production are complex mechanism, poor repeatability, and the fluctuation of production process is much higher than that of other chemical batch processes. Due to differences in seed quality, changes in raw material composition and ratio ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12M1/36

Inventor 袁景淇王卓李运锋薛耀锋张溥明

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com