Construction method for underground structure through half reverse course of action of inverting connection

A technology of reverse connection and construction method, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of difficult reinforcement treatment in construction joints, water seepage in construction joints, high treatment costs, etc., and achieve extensive economic benefits and social benefits. Benefits, convenient construction, and the effect of saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

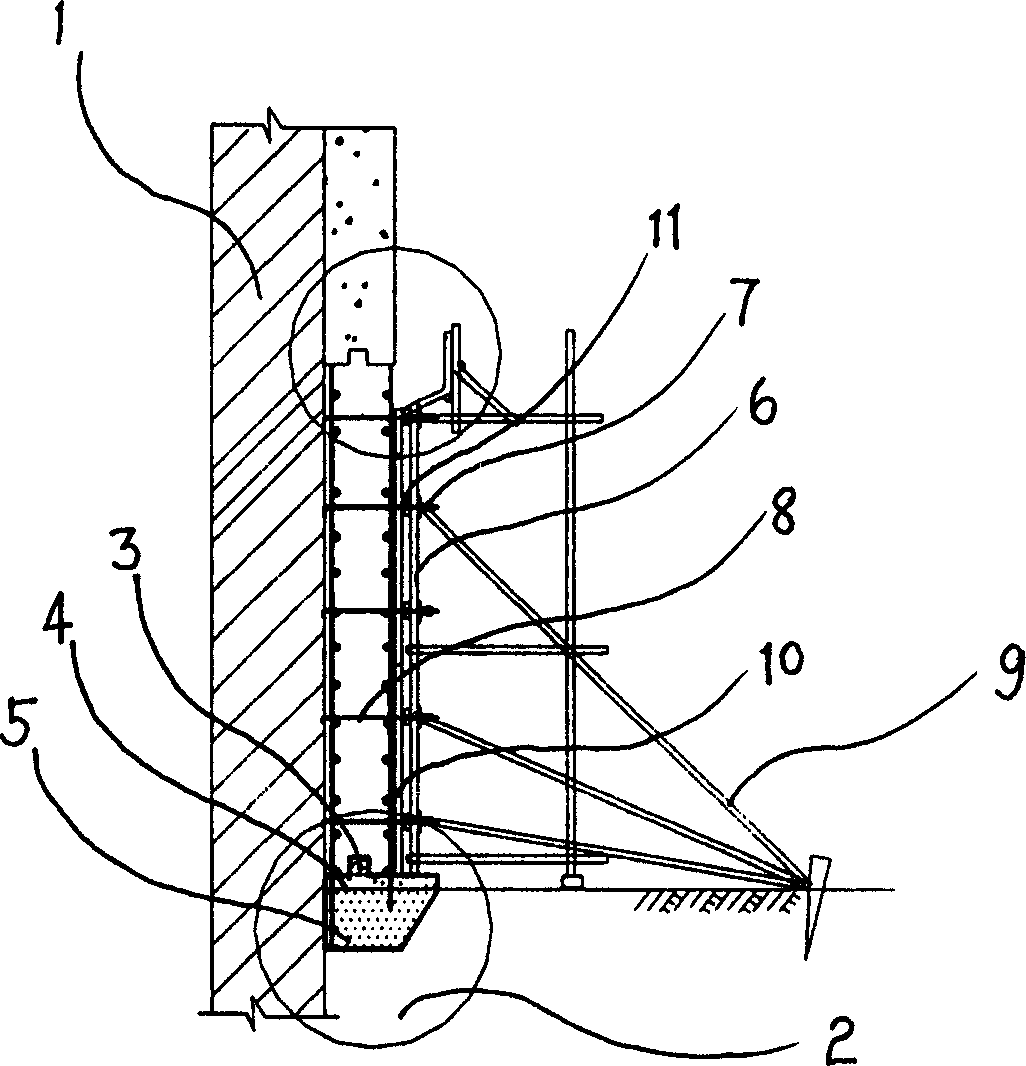

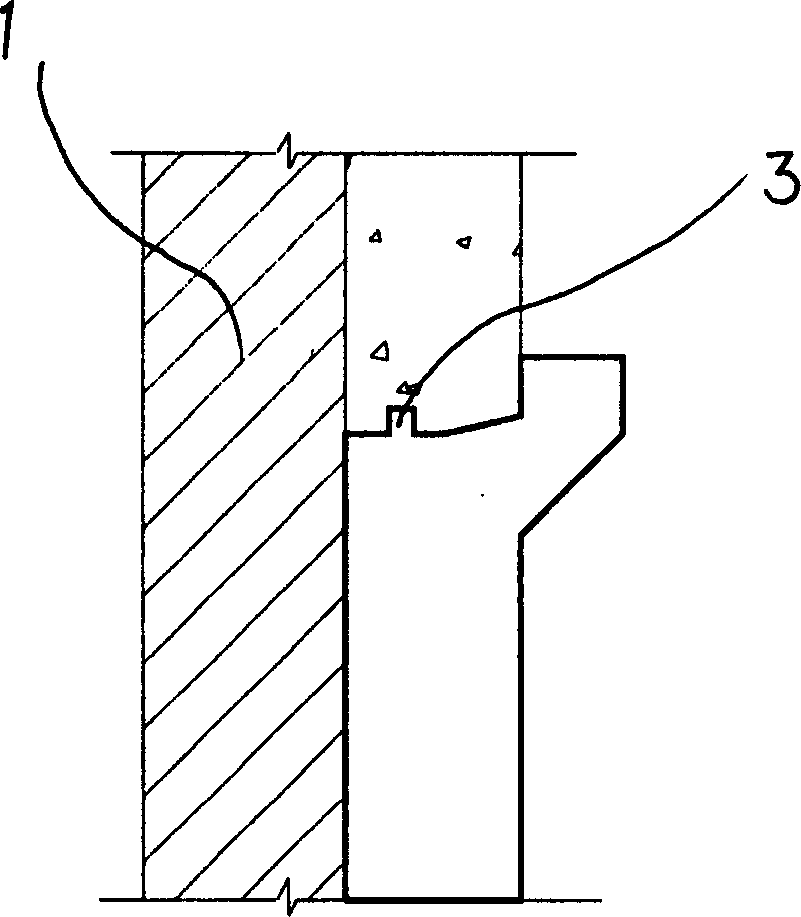

Embodiment 1

[0030] Example 1: A circular underground structure with a depth of -32.75m and a diameter of 18.57m on a soft soil foundation is surrounded by an underground diaphragm wall at a depth of -44.55m. Segmented semi-reverse construction method reverse connection construction method. The vertical reinforcement of the segmental semi-reversed sand tank joints is connected by spot welding and binding, and the segmental reverse sand tank joints are of tenon structure (depth 1.40m, width 1.5m, wooden 80mm*100mm tenon and groove, medium coarse sand Layer-by-layer compaction), 5-8m section reverse earthwork excavation, 300-500mm layered sand filling and compaction, 20 vertical reinforcement, pouring 80-100mm mortar cushion, wooden tenon and groove positioning, horizontal steel bar binding For construction, a 600*400mm door hole is reserved for formwork construction, and the 1200mm*300mm waist ring beam of the beam-slab structure is used to act as a false corbel, and the concrete is poured...

Embodiment 2

[0031] Example 2: A circular underground structure with a depth of -29.5m and a diameter of 14.5m on a soft soil foundation is surrounded by an underground diaphragm wall at a depth of -41.5m. Construction method of segmented reverse sand tank joint. Spot welding and binding are selected for the vertical steel bars of the joints of subsection reverse sand grooves, and the tenon structure of the subsection reverse sand groove joints (depth 1.40m, width 1.5m, wooden 80mm*100mm tenon and groove, medium coarse sand Layer tamping), 5-10m section reverse earthwork excavation, 300-500mm layered sand filling and tamping, 20 vertical reinforcement, pouring 80-100mm concrete cushion, wooden tenon and groove positioning, template construction reservation 600*400mm door hole, using the 1100mm*300mm waist ring beam of the beam-slab structure to act as a false corbel, and the 500-600mm concrete is poured in layers. Implementation effect: There are no harmful cracks in the construction joi...

Embodiment 3

[0032] Example 3: A circular underground structure with a depth of -33.0m and a diameter of 28.1m on a soft soil foundation is surrounded by an underground diaphragm wall at a depth of -53.0m. Construction method of segmented reverse sand tank joint. Spot welding and binding are selected for the vertical steel bars of the sand groove joints of subsections, and the tenon structure of the joints of sand grooves is reversed in sections (depth 1.60m, width 0.8-1.6m, wooden 100mm*100mm tenon and groove, medium thick Sand layered and compacted), 5-8m segmental reverse earthwork excavation, 300-500mm layered sand filling and compaction, 25 vertical reinforcement, pouring 80-100mm concrete or 100mm sand cushion, wooden tongue and groove positioning , leave 600*400mm door holes for formwork construction, set 400mm*700mm false corbels, and pour concrete in layers of 500-600mm. Implementation effect: There are no harmful cracks in the construction joints of the semi-reverse constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com