XPS board with steel wire mesh with oblique inserted wire

A technology of extruded polystyrene board and steel wire mesh frame is applied in the field of building thermal insulation materials, which can solve the problems of low compressive shear strength, high thermal conductivity, bonding force, and the disadvantage of thermal insulation index and external surface stability, and achieve high shear resistance. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Referring now to the drawings in detail, preferred embodiments of the present invention will be described.

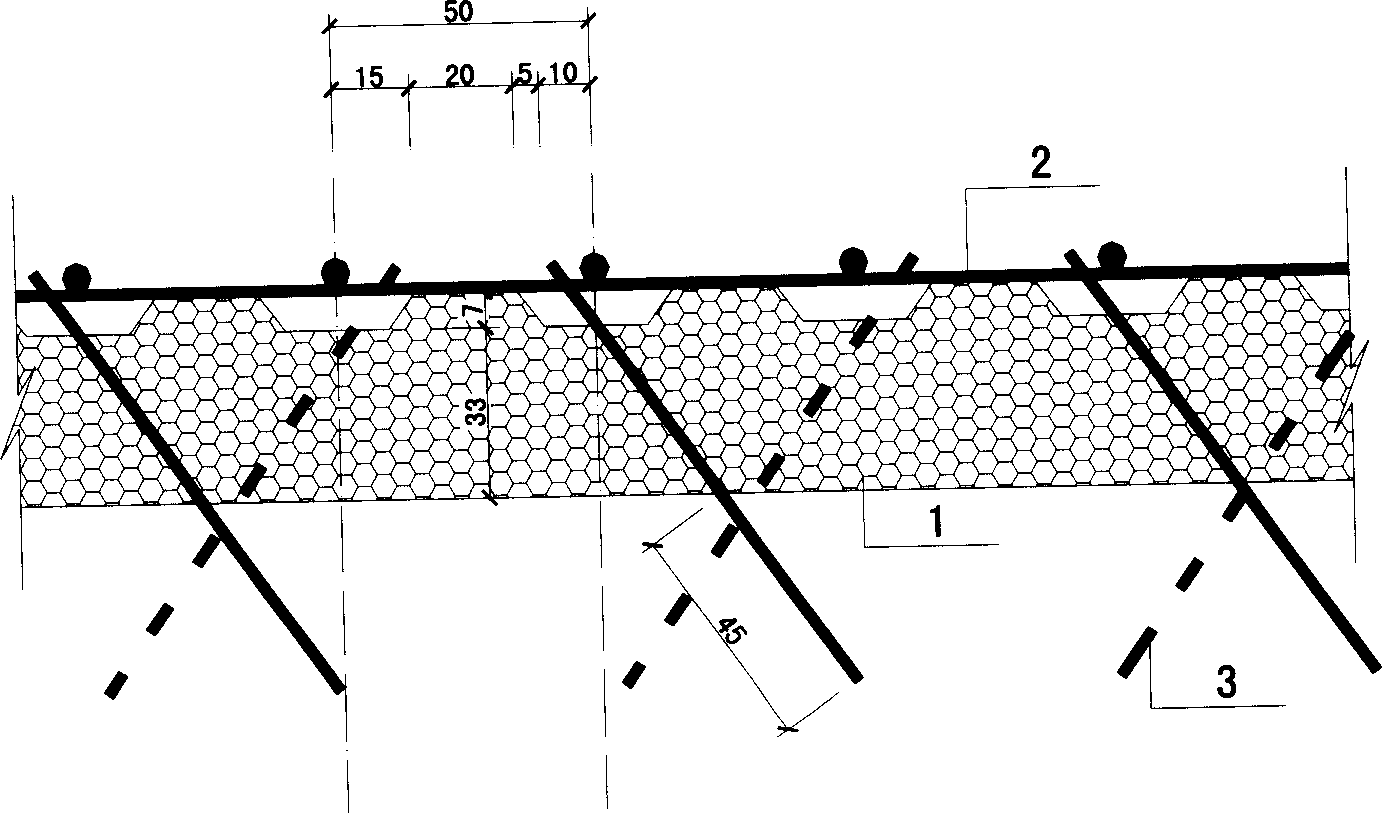

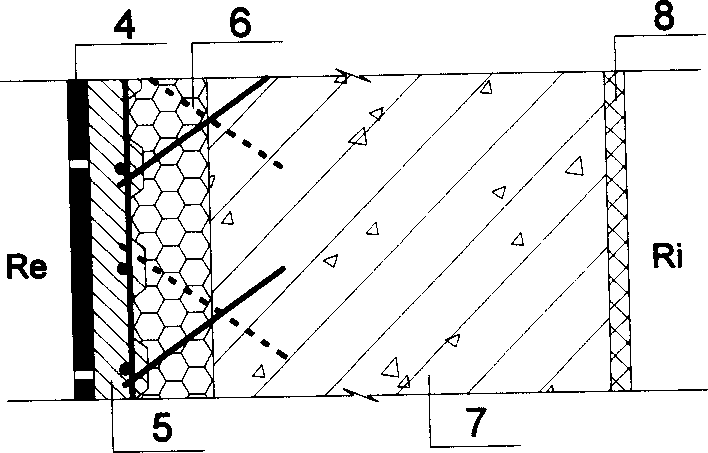

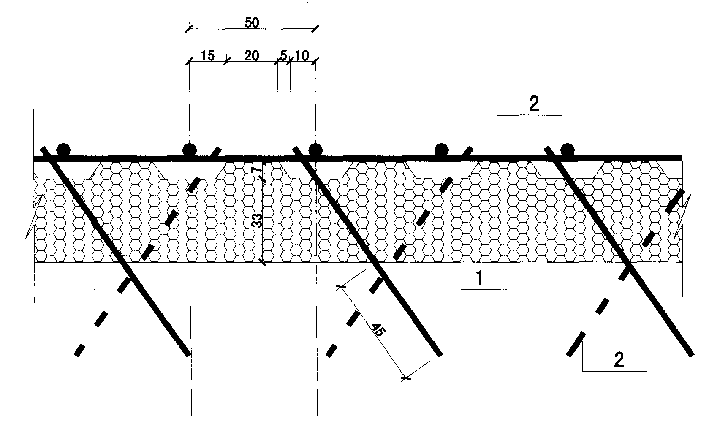

[0016] Using 40mm thick extruded polystyrene board, board length 2400mm, board width 600mm, single-sided groove processing, groove depth 7mm, groove center distance 50mm. The galvanized steel wire with a diameter of ф2.5mm is obliquely inserted, and the galvanized steel wire exposes about 45mm on the side without the groove, and the number of galvanized steel wires is ≤200 per square meter. On the grooved side of the extruded polystyrene board, the mesh opening is 50×50mm, the low-carbon steel wire diameter is ф2.0mm low-carbon (galvanized) steel wire mesh, and welded with the inserted galvanized steel wire, the strength of the solder joint : Tensile strength ≥ 300N. A product of the present invention can be produced by spraying the interface treatment agent on both sides. The combination of this product and the reinforced concrete wall reaches 0.5Mpa; on the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com