Array type micro-electromechanic capacitor microphone

A technology of capacitive microphones and micro-electromechanical capacitors, applied in electrical components, transducer circuits, electrostatic transducer microphones, etc., can solve problems such as the difficulty of integrating capacitive microphones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Before explaining the technical details of the present invention in detail, it should be specifically stated that, for the sake of clarity, the following are all described with actual manufacturing processes, as well as various explanatory figures, units, materials, etc., but familiar sound energy, electrical energy, mechanical energy Theories and mutual conversion relations, micro-electro-mechanical system technology process, and microphone technicians can easily know that the present invention is not limited by the description of the actual process, and the numbers, unit materials, etc. The practical application of the present invention.

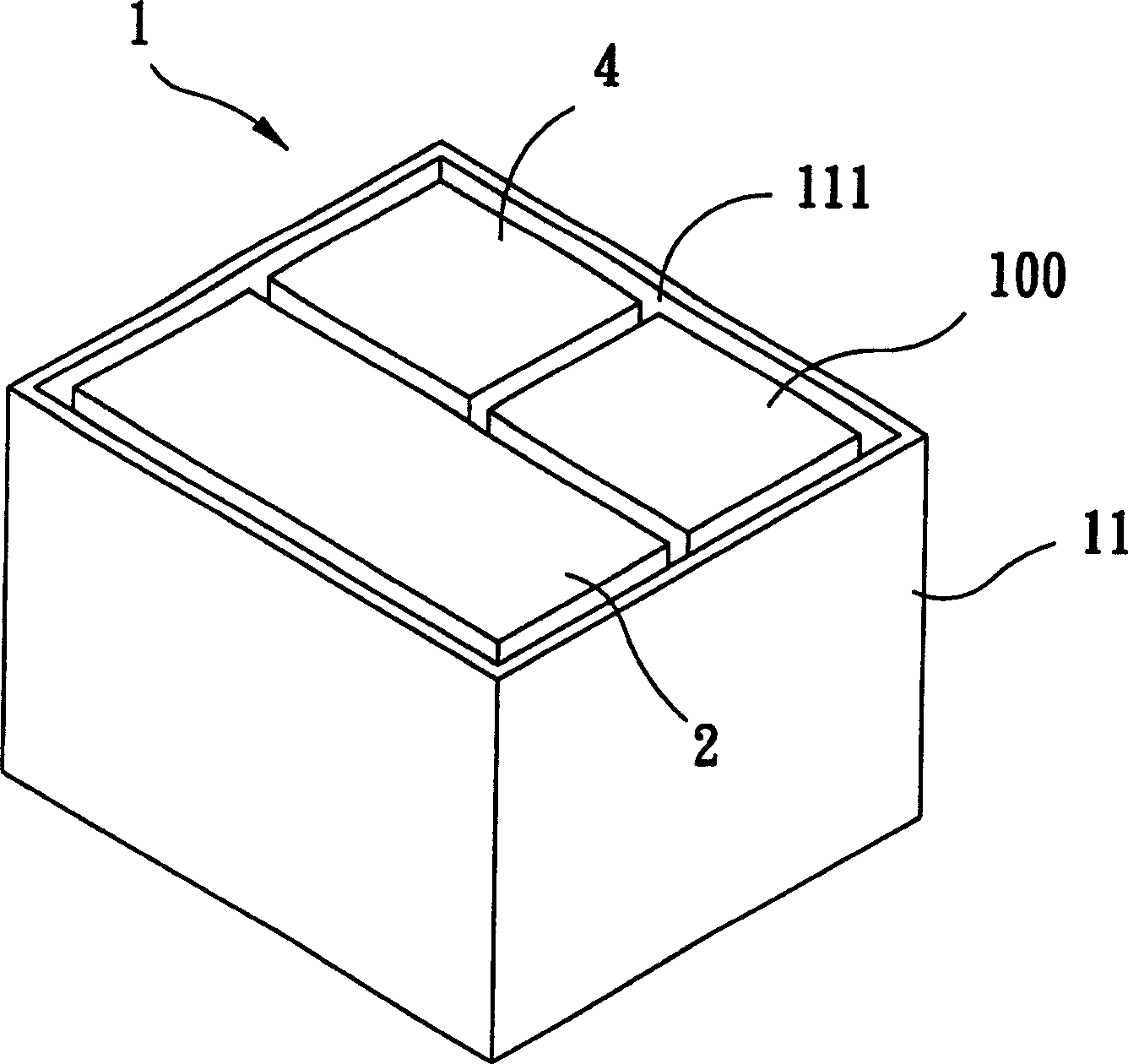

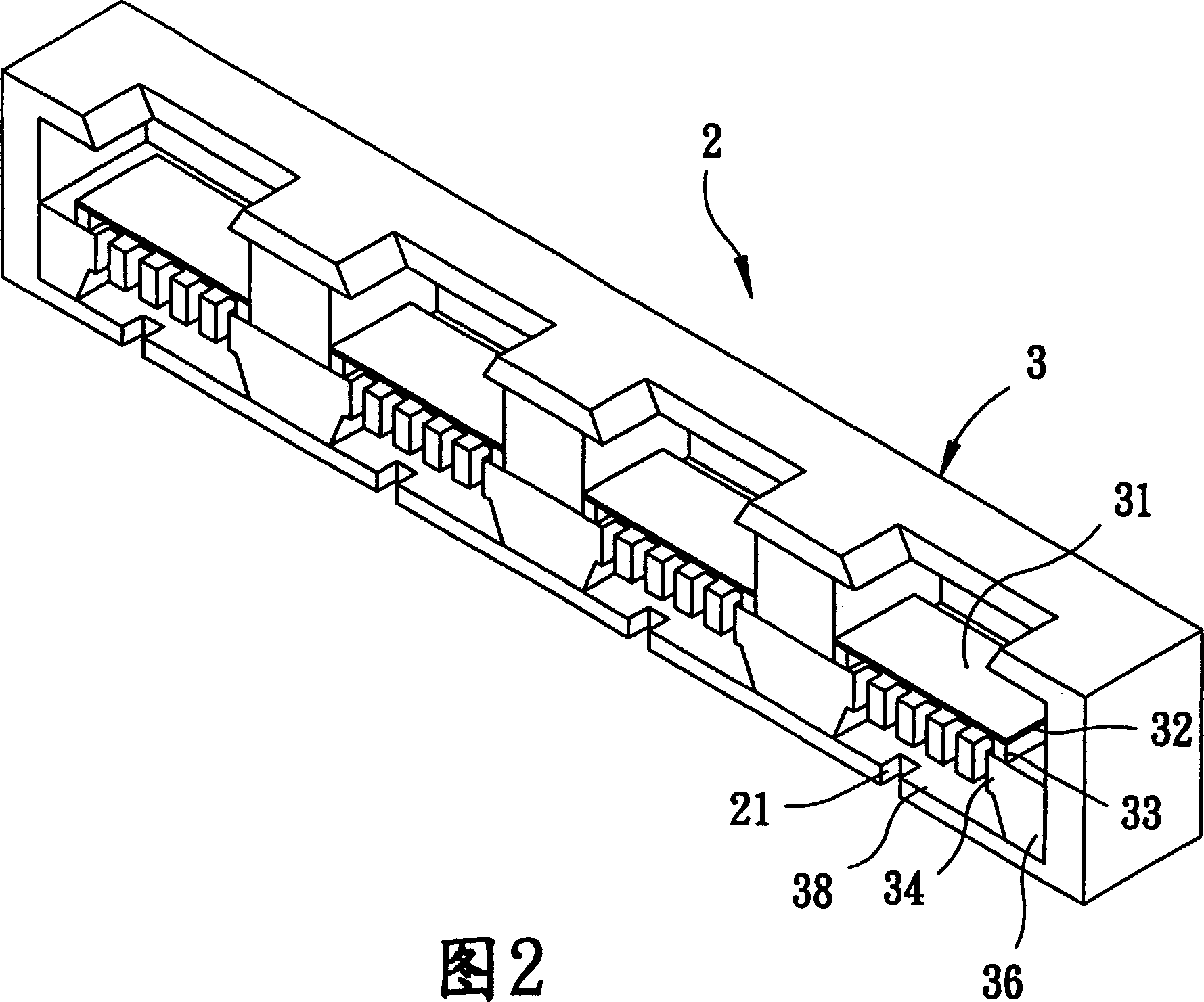

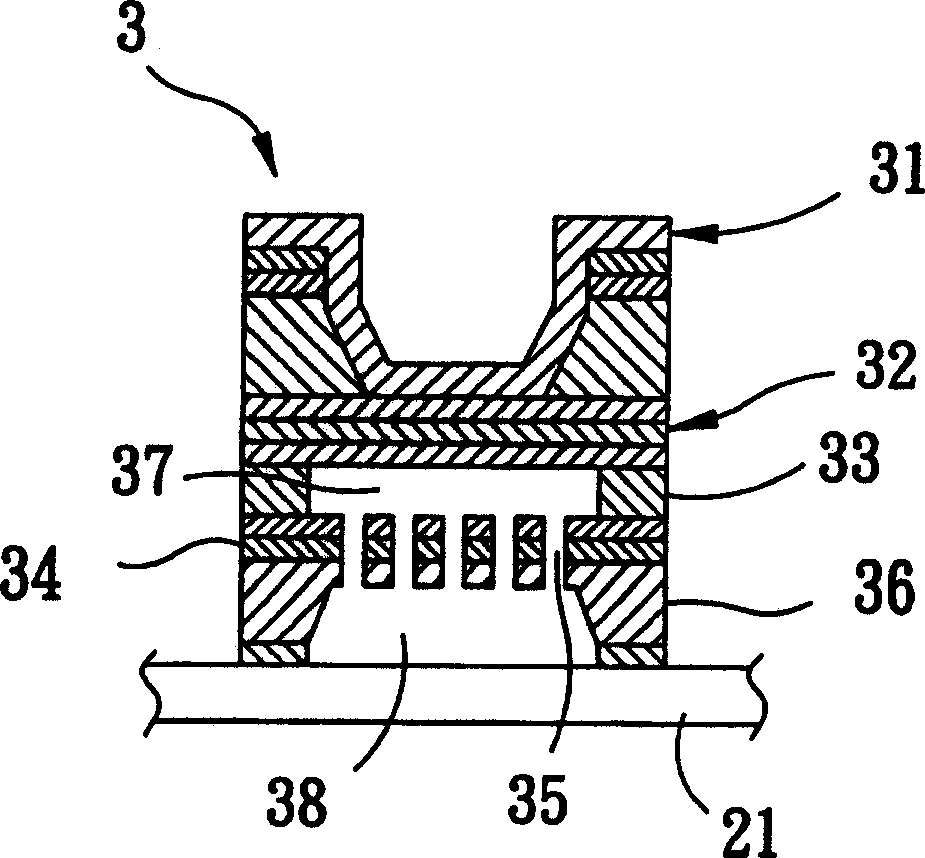

[0044] Such as figure 1 , as shown in FIG. 2 , an array microelectromechanical condenser microphone 1 of the present invention includes a base 11 , a condenser microphone device 2 , an analog computing device 4 , and a field effect transistor (FieldEmission Transistor; FET) 100 .

[0045] The base 11 defines an accommodating space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com