Method for producing grass planting brick and water permeable brick using reclaimed waste plastic

A technology of waste plastics and grass-planting bricks, applied in the field of manufacturing building materials products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

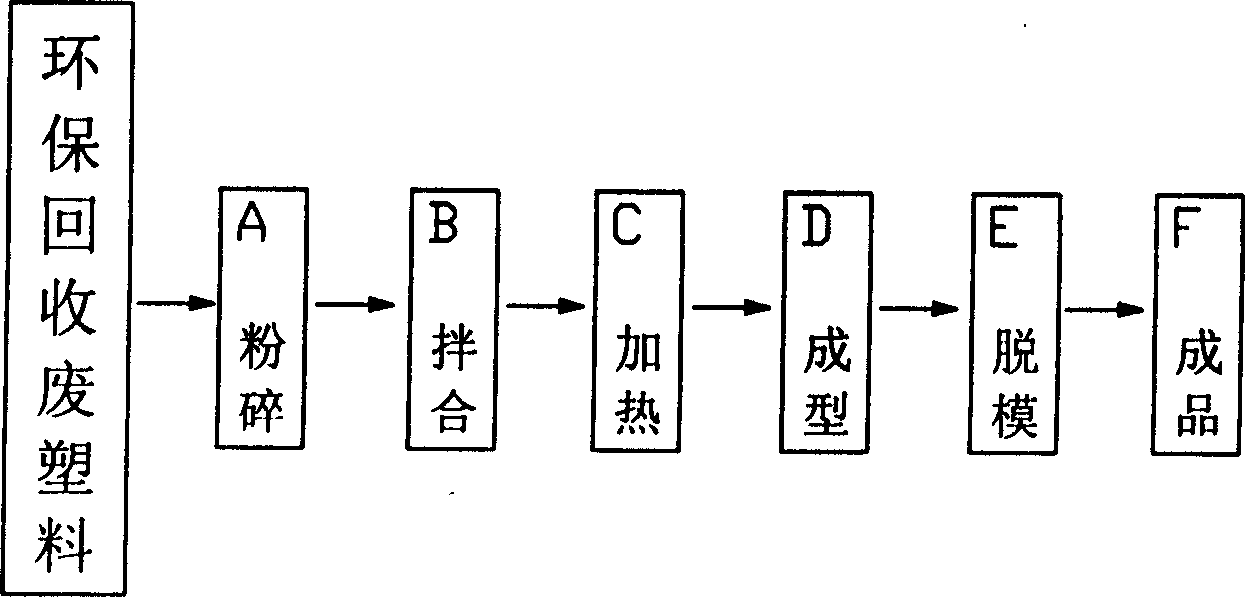

[0047] See shown in accompanying drawing 1: this figure is the manufacturing flowchart of the present invention, and it mainly is made up of following several steps:

[0048] A. Crushing, crushing environmentally friendly recycled waste plastics into suitable particle shapes.

[0049] B. Mixing, mixing the crushed waste plastics requires proportion of silica and coloring materials.

[0050] C. Heating, heating the evenly stirred raw materials into a fluid state.

[0051] D. Forming, casting the heated raw material into the required mold.

[0052] E. Demoulding, after the casting molding raw materials are cooled, the demoulding work can be carried out.

[0053] F. Finished product, after demoulding, it is a finished product, which can be shipped at any time and delivered to the site for assembly.

[0054] Thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com