High-temperature superconductive magnetic levitation device

A high-temperature superconducting and magnetic levitation technology, applied in transportation and packaging, electric traction, electric vehicles, etc., can solve problems such as resistance heating, low levitation height, and limited current-carrying capacity of wires, so as to reduce power and cost and simplify control System, to achieve the effect of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1

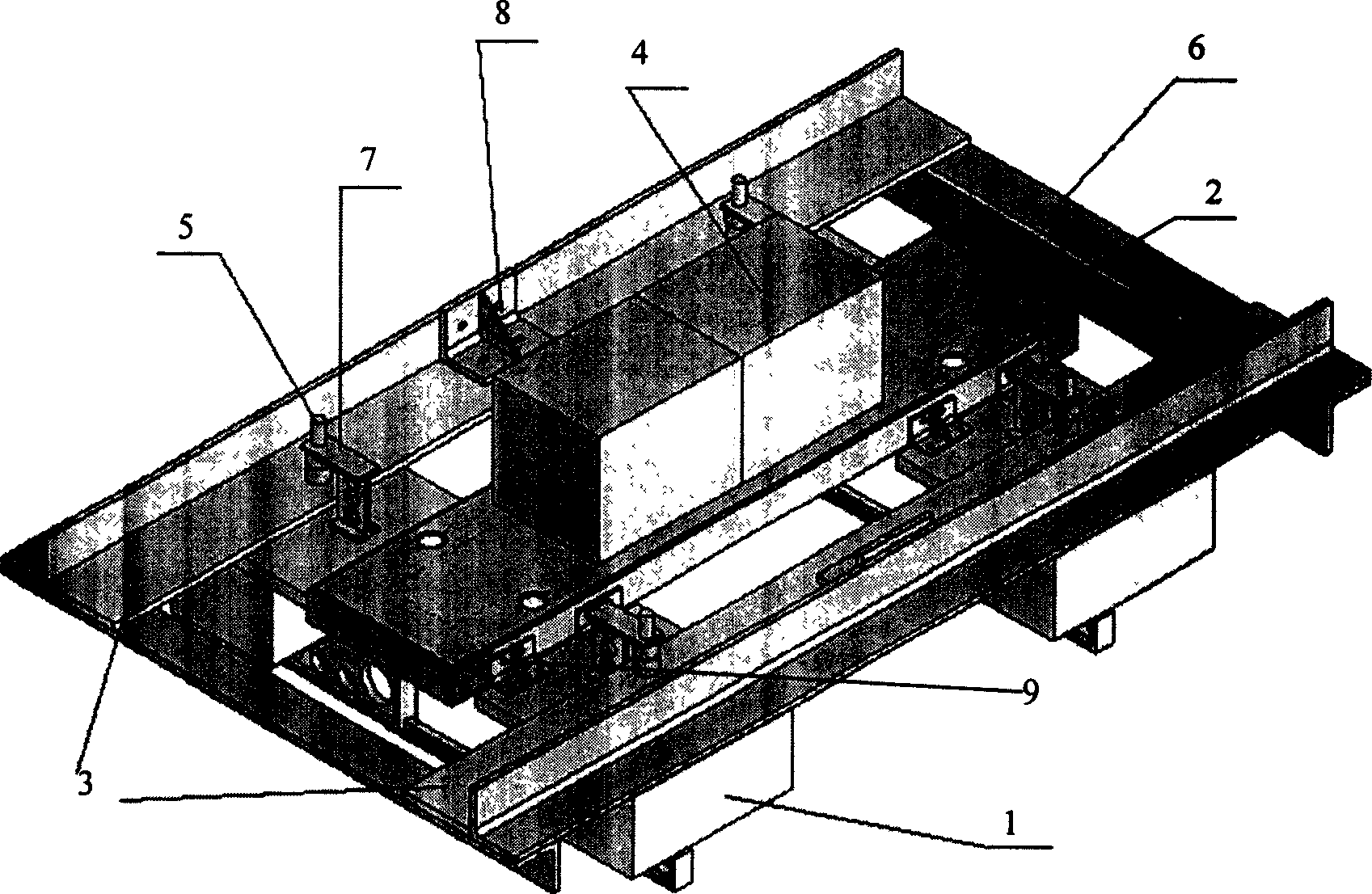

[0050] A high-temperature superconducting magnetic levitation device embodiment (1) as shown in Figure (1), a kind of high-temperature superconducting magnetic levitation device embodiment (1) implemented by the present invention is a principle experimental car body, a high-temperature The superconducting magnetic levitation device is characterized in that the high-temperature superconducting magnet assembly (1) is connected with the car body (2) through the magnet and the car body connecting piece (9). The two steel rails (3) on both sides are placed on a frame made of angle steel. In order to prevent the deformation of the steel guide rail from being too large, we use angle steel reinforcements (8) to connect with the frame. The air gap sensor (5) is integrally formed with the high temperature superconducting magnet assembly through a connecting piece (7). The air gap sensor (5) is an eddy current sensor, and the eddy current sensor detects the relative position between the...

Embodiment (2

[0057] A high-temperature superconducting magnetic levitation device embodiment (1) as shown in Figure (1), a kind of high-temperature superconducting magnetic levitation device embodiment (1) implemented by the present invention is a principle experimental car body, a high-temperature The superconducting magnetic levitation device is characterized in that the high-temperature superconducting magnet assembly (1) is connected with the car body (2) through the magnet and the car body connecting piece (9). The two steel rails (3) on both sides are placed on a frame made of angle steel. In order to prevent the deformation of the steel guide rail from being too large, we use angle steel reinforcements (8) to connect with the frame. The air gap sensor (5) is integrally formed with the high temperature superconducting magnet assembly through a connecting piece (7). The air gap sensor (5) is an eddy current sensor, and the eddy current sensor detects the relative position between the...

Embodiment (3

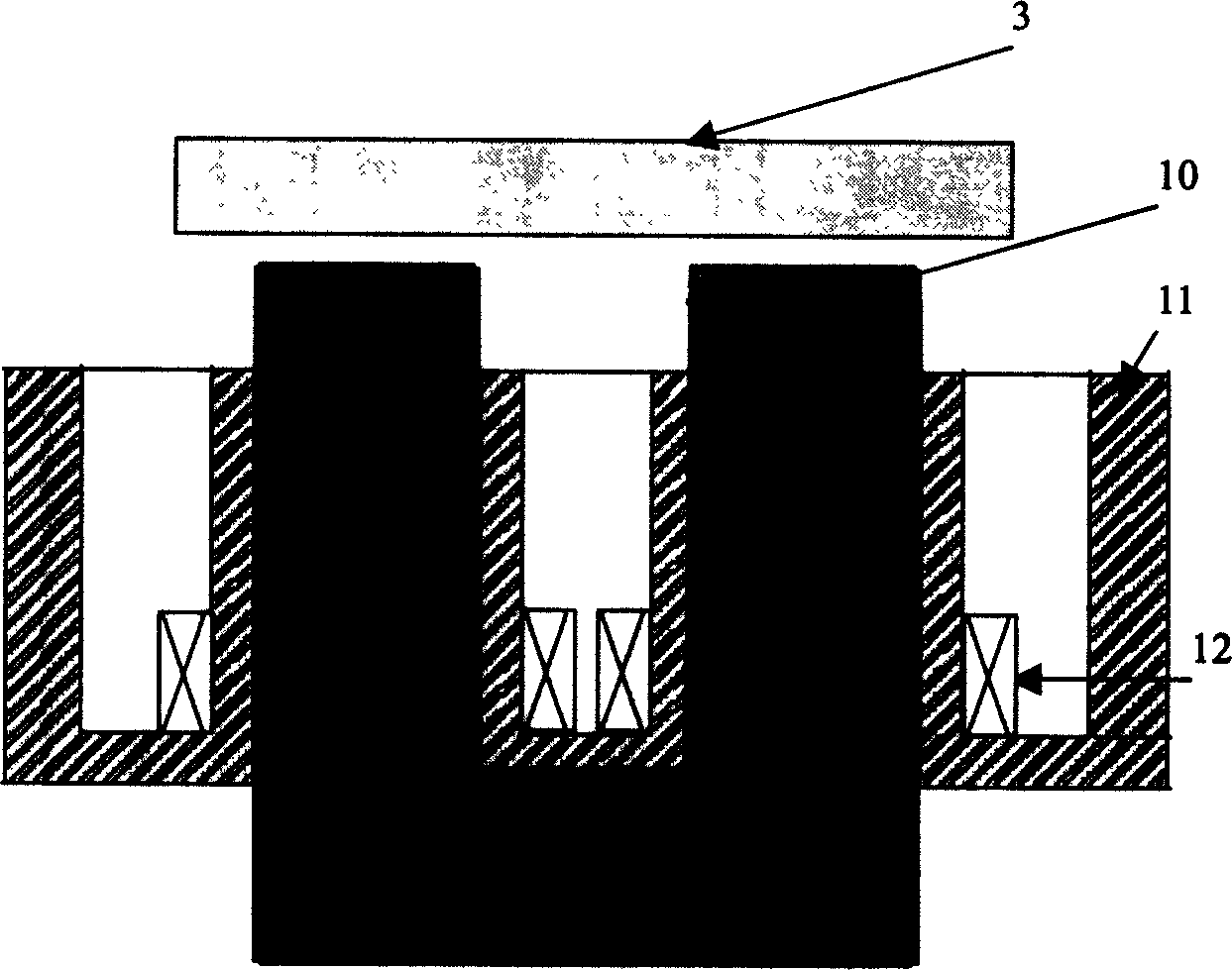

[0065] An example (3) of a high-temperature superconducting magnetic levitation device is shown in Figure (5). On the basis of the embodiment (2), we added the permanent magnet (14) as a third means that can provide the suspension force in the vertical direction. The permanent magnet can be used as a part of the U-shaped iron core, integrated in a magnetic circuit, or used as a separate magnetic circuit.

[0066] Compared with the high-speed maglev train, one of the characteristics of the superconducting maglev device of the present invention is that the car body runs at a low speed; it is suitable for short-distance urban traffic, sightseeing and entertainment with low energy consumption, low vibration, low noise, and high environmental protection transportation tool, which will greatly reduce the technical and infrastructure costs of the superconducting magnetic levitation device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com