Automatic flexible producing assembling system

An assembly system and flexible manufacturing technology, applied in the field of automated flexible manufacturing assembly systems, can solve the problems of complex structure, single action, high cost, etc., and achieve the effect of simple actuator, comprehensive functions, and large storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, embodiment is described.

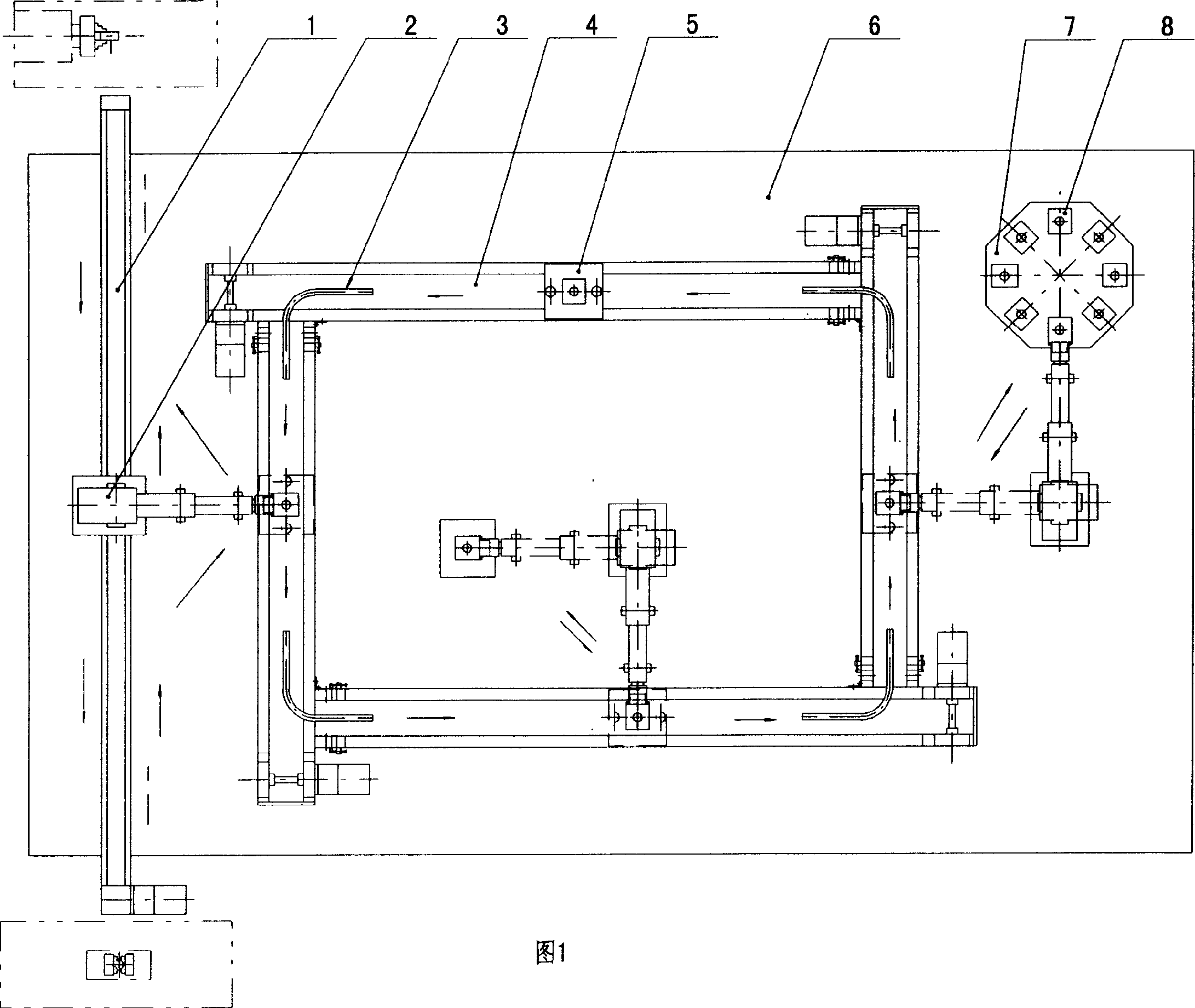

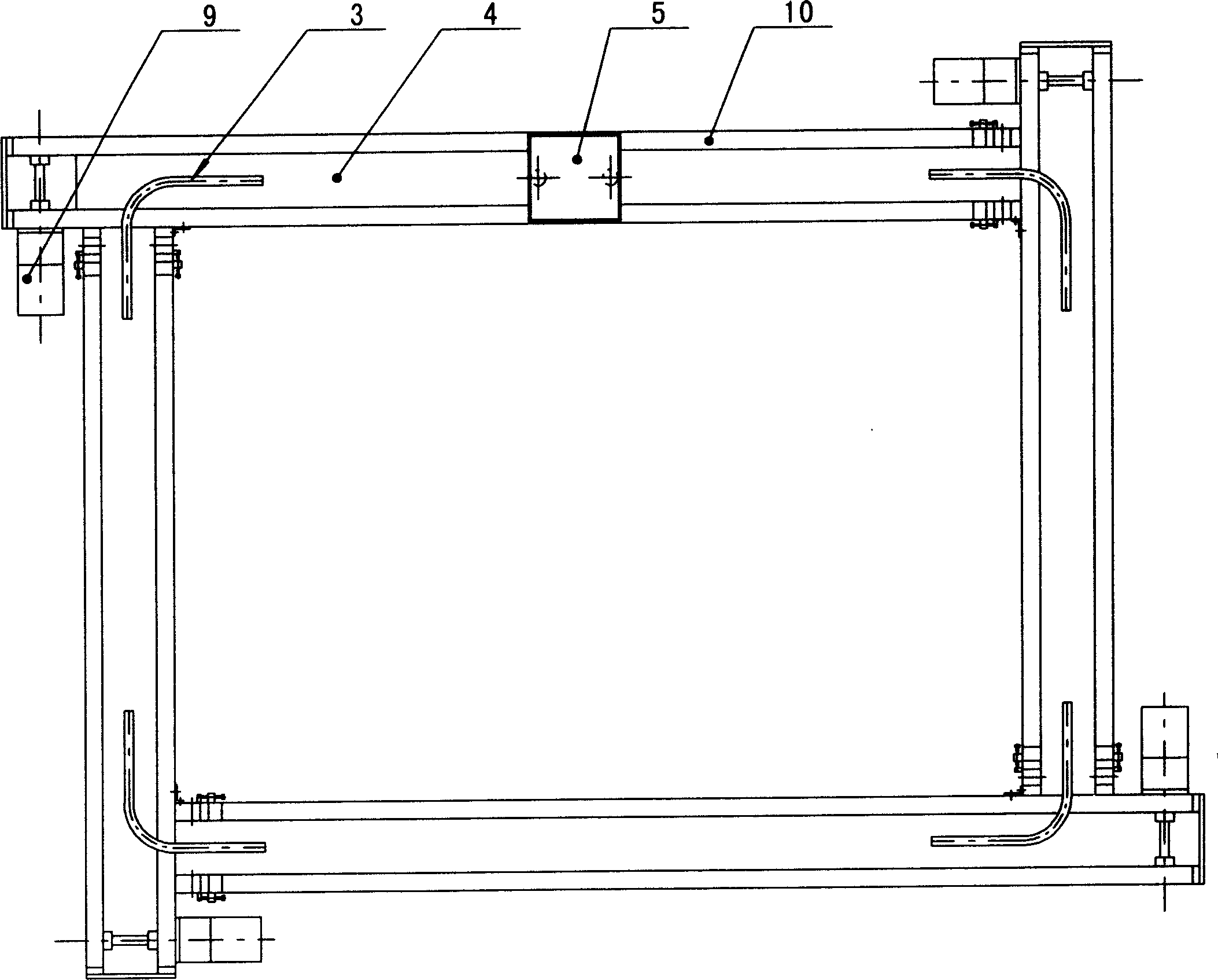

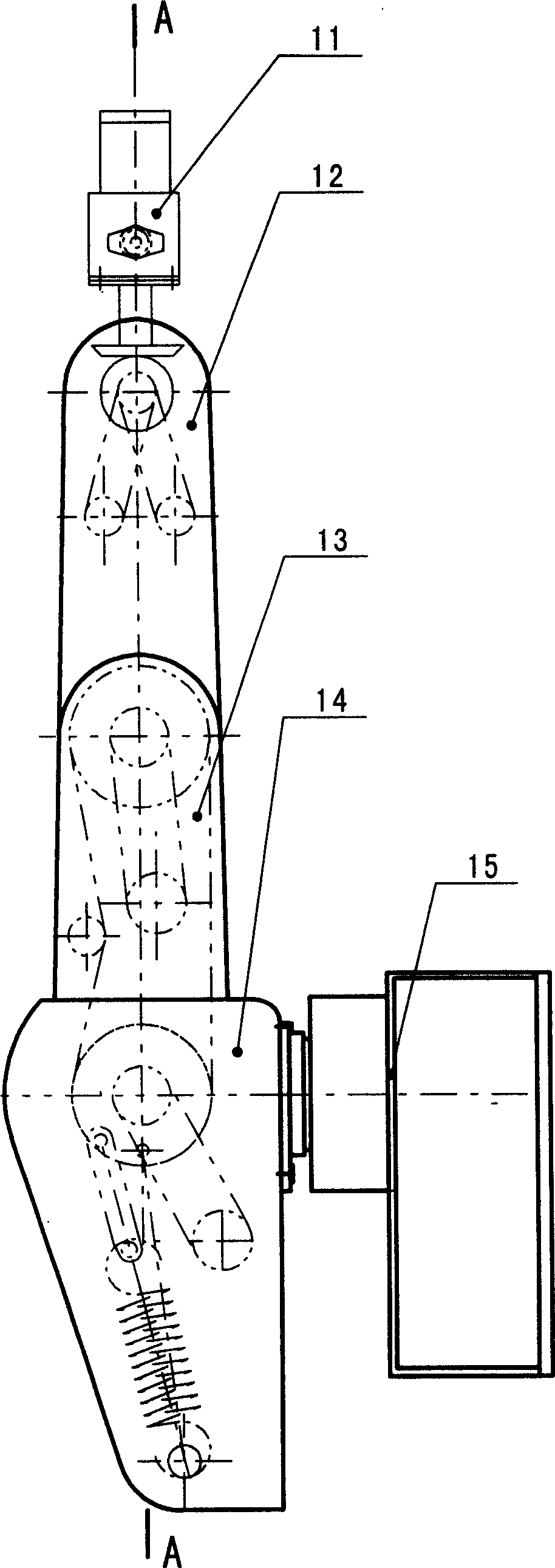

[0025] First refer to Figure 1: various components of the automated flexible manufacturing assembly system are installed on the system working platform 6, and the components installed on the system working platform include: the parts transmission line 4, the manipulator 2 and the parts library 7, and a straight line is also installed Transmission line 1, the two ends of the linear transmission line are equipped with automatic processing lathes (CNC) and other processing devices (as shown in dotted lines), and the manipulator running on it is used to take the parts from the transmission line to the lathe for processing, and then place them Back to the parts transmission line. The part transmission line conveying parts adopts the part tray 5 that can run on the part transmission line. In this embodiment, there are three manipulators shown, which are respectively placed at the warehouse-in position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com