Composite silk and its preparing method

A composite silk and tencel technology, applied in textiles, papermaking, yarn and other directions, can solve the problems of inability to use processing, mixed fibers, and unable to fully reflect the advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Tencel adopts the conventional method: blowing - carding - pre-merging into a strip, the quantitative of a strip is 18 grams / 5 meters;

[0029] 1# silk cotton strips are cut into b strips by conventional methods, and the weight of b strips is 10 grams / 5 meters;

[0030] The tencel-spun silk mixture adopts the conventional method: blowing - carding - pre-cutting into c strips, and the weight is 15 grams / 5 meters.

[0031] Among them, the fineness of silk is 0.8dtex; the fineness of Tencel is 1.2dtex;

[0032] The temperature during spinning is 25°C and the relative humidity is 80%;

[0033] The linear speed of the output roller of the air-jet spinning is 195 m / min.

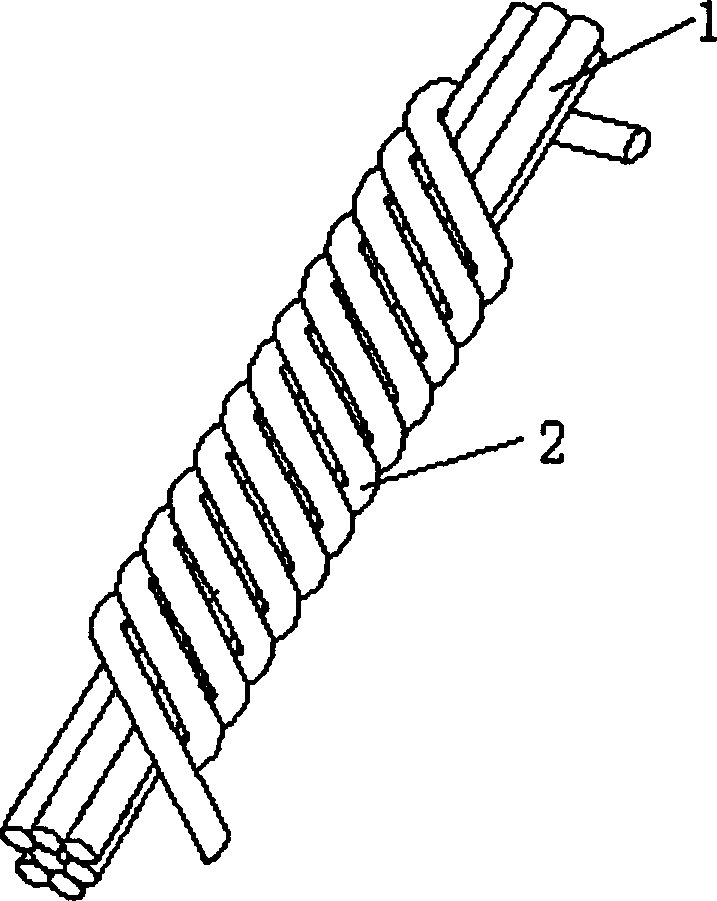

[0034] That is, the tencel-spun silk composite silk of the present invention is obtained, and its structure is as follows figure 1 . Adopt Q / WFAS016-2003 enterprise standard to test the above-mentioned Tencel-silk composite yarn, and the results are as follows: Excellent product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com